A method of controlling an electric water heater

A technology for electric water heaters and control methods, applied to fluid heaters, lighting and heating equipment, etc., can solve problems such as scalding users and insufficient hot water, and achieve the effect of satisfying bathing experience, improving water safety and water experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

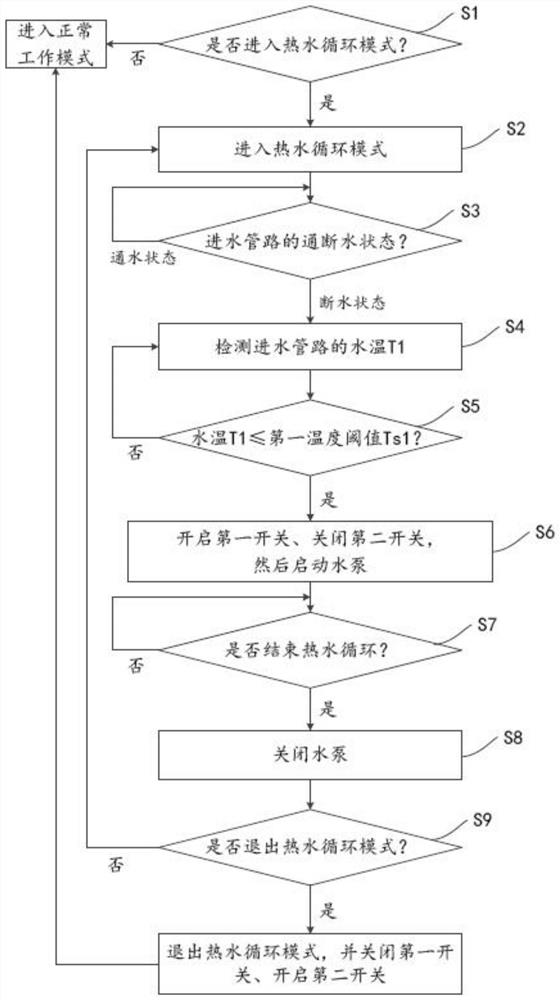

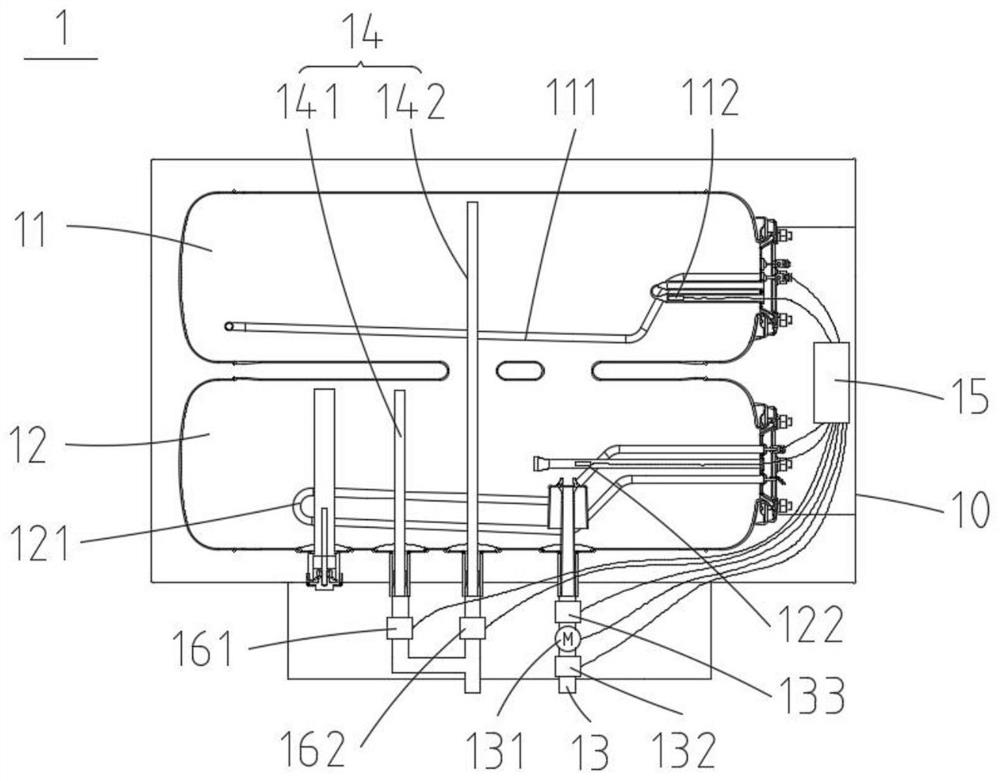

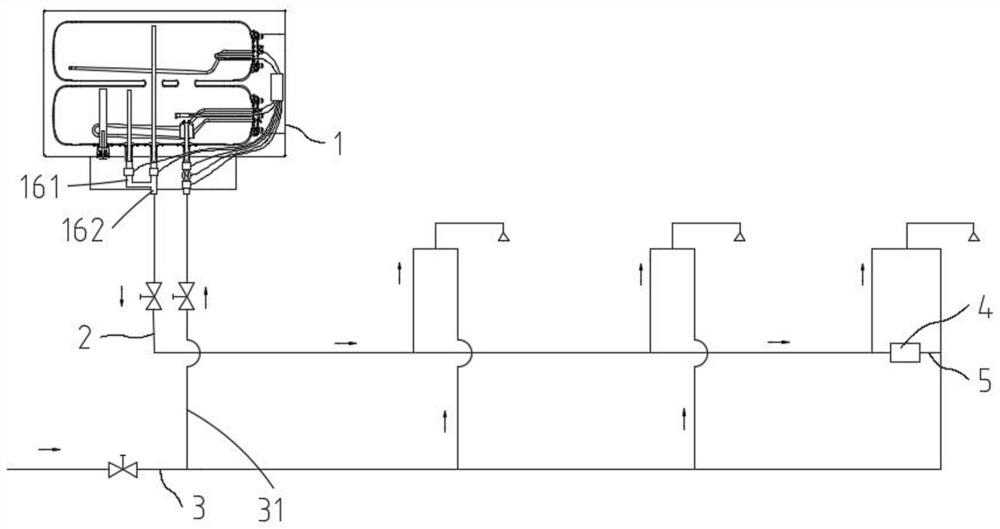

[0030] Such as figure 2 As shown, a control method for an electric water heater, the electric water heater 1 includes a box body 10, an upper liner 11, a lower liner 12, a water inlet pipeline 13, a water outlet pipeline 14 and an electric control assembly 15, and the box body 10 is provided with The upper inner tank 11 and the lower inner tank 12 are connected to each other, the upper inner tank 11 is arranged directly above the lower inner tank 12 and its water temperature T4 is not less than the water temperature T3 of the lower inner tank 12 . A water pump 131 , a temperature detection device 132 and a water flow detection device 133 are provided on the water inlet pipeline 13 . The water outlet pipeline 14 includes a first water outlet pipe 141 and a second water outlet pipe 142. The upper end of the first water outlet pipe 141 vertically penetrates the bottom of the box body 10 and then extends into the lower inner container 12 for discharging the lower inner container ...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is that the control method for continuously judging whether to end the hot water circulation is different. Specifically, in step S7, it is continuously judged whether to end the hot water cycle, which continuously judges whether the working time t of the water pump 131 reaches the preset time value ts, and determines whether to end the hot water cycle based on the judgment result.

[0054] In this embodiment, the electronic control unit 15 is integrated with a timer, and the timer starts counting t when the water pump 131 starts working. If the working time t=the preset time value ts, it indicates that the hot water circulation needs to be ended. If the working time t

[0055] It can be seen that by detecting and judging whether the working time t of the w...

Embodiment 3

[0057] The difference between this embodiment and embodiment 1 or embodiment 2 is that the control method for continuously judging whether to end the hot water circulation is different. Specifically, in step S7, it is continuously judged whether to end the hot water circulation, and the water flow increase value ΔQ of the water inlet pipeline 13 is sampled once at a continuous interval time Δt, and it is judged whether the water flow increase value ΔQ is greater than or equal to the preset water flow rate Qs , and decide whether to end the hot water circulation based on the judgment result.

[0058] In this embodiment, the electronic control component 15 is integrated with a timer. When the water pump 131 or the lower heating device 121 starts to work, the timer starts counting. If the water flow increase value △Q of the water inlet pipeline 13 is greater than or equal to the preset water flow rate Qs, it indicates that the user is using hot water during the hot water circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com