Phase change heat storage asphalt and preparation method thereof

A phase change and asphalt technology, applied in chemical instruments and methods, heat exchange materials, building components, etc., can solve the problems of lack of heat storage and temperature control function, high cost, and achieve performance improvement, reduction in dosage, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

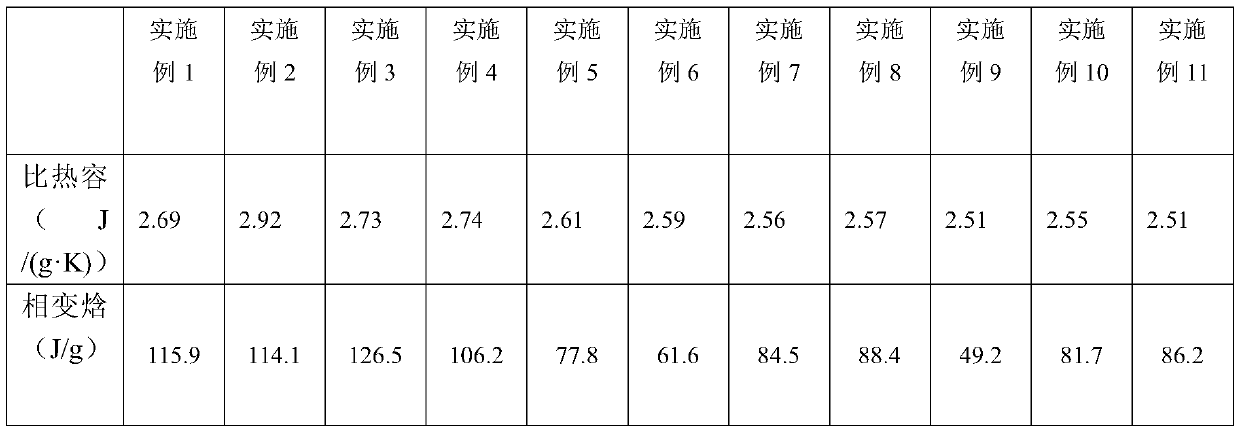

Embodiment 1

[0038] Phase change heat storage asphalt, including the following components by weight: 20 parts of asphalt and 20 parts of graphite adsorption phase change energy storage powder, wherein, the graphite adsorption phase change energy storage powder includes the following components by weight Parts: 100 parts of paraffin and 5 parts of worm-like expanded graphite, the expansion rate of the worm-like expanded graphite is 500ml / g, the particle size is 100 mesh, the expansion multiple is 400 times, and the bulk density is 0.2g / cm 3 .

Embodiment 2

[0040] Phase change heat storage asphalt, including the following components by weight: phase change heat storage asphalt, including the following components by weight: 70 parts of asphalt and 70 parts of graphite adsorption phase change energy storage powder, wherein the graphite adsorption phase Variable energy storage powder, including the following components in parts by weight: 100 parts of paraffin and 9 parts of worm-like expanded graphite, the expansion rate of the worm-like expanded graphite is 600ml / g, the particle size is 200 mesh, and the expansion ratio is 600 times , the bulk density is 0.5g / cm 3 .

Embodiment 3

[0042] The phase change heat storage asphalt includes the following components by weight: 40 parts of asphalt and 50 parts of graphite adsorption phase change energy storage powder, wherein the graphite adsorption phase change energy storage powder includes the following components by weight: 100 parts of fatty acid and 6 parts of worm-like expanded graphite, the expansion rate of the worm-like expanded graphite is 100ml / g, the particle size is 150 mesh, the expansion multiple is 500 times, and the bulk density is 0.3g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap