Controlling of a work machine based on sensed variables

A machine and mobile operation technology, applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of inability to accurately estimate the volume of the contents, difficulty in measuring efficiency, and the efficiency of the soil removal process. Low and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

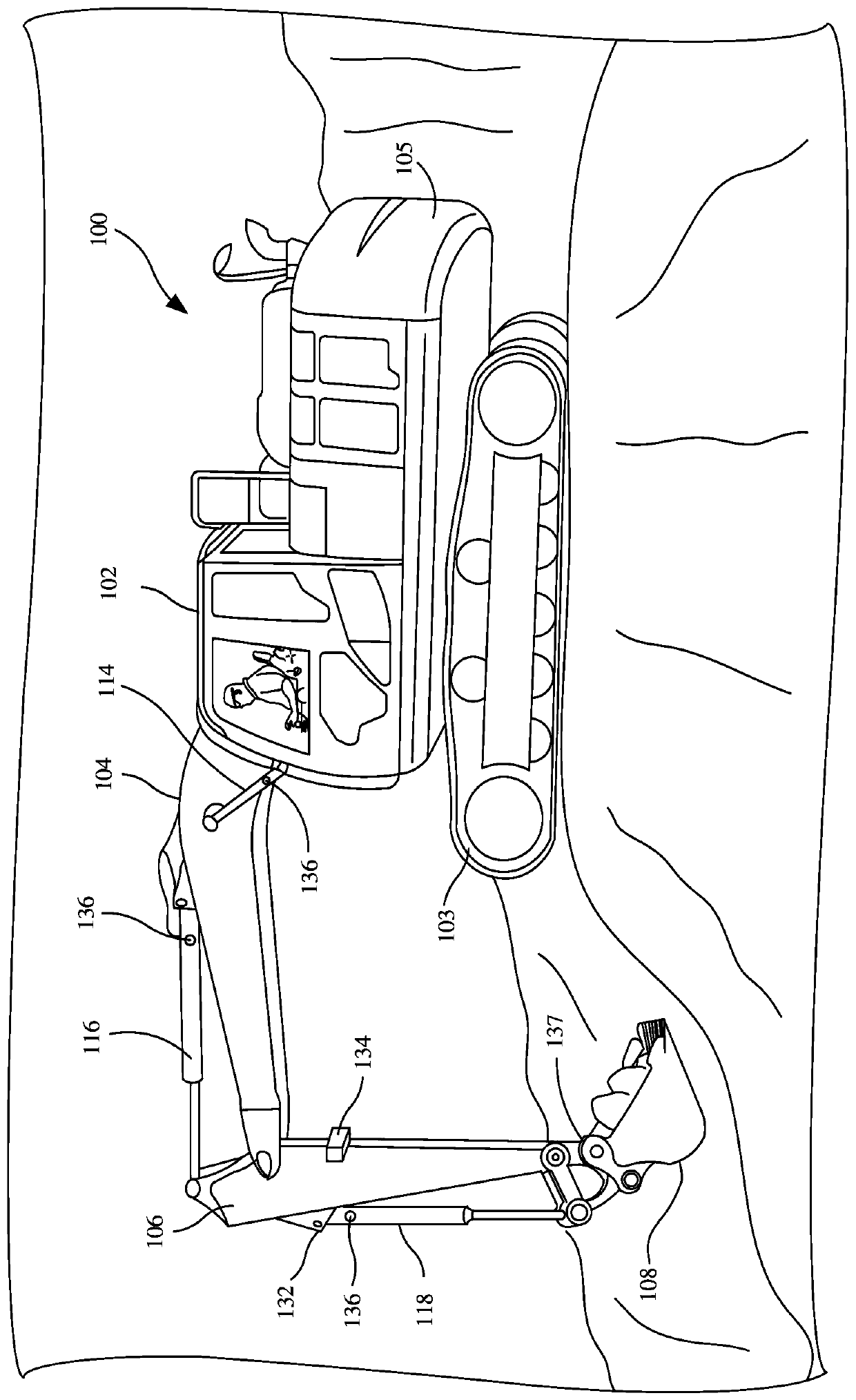

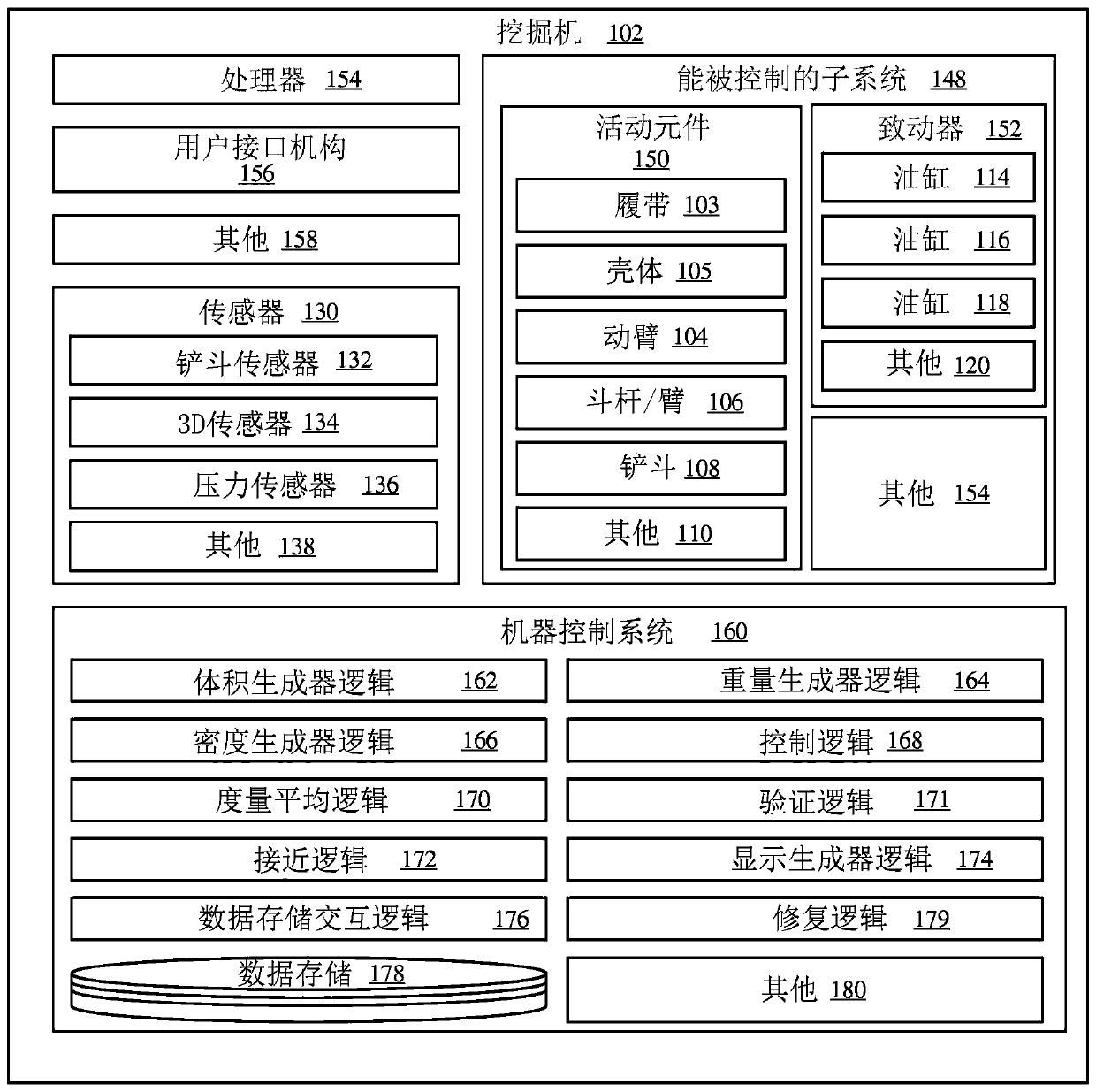

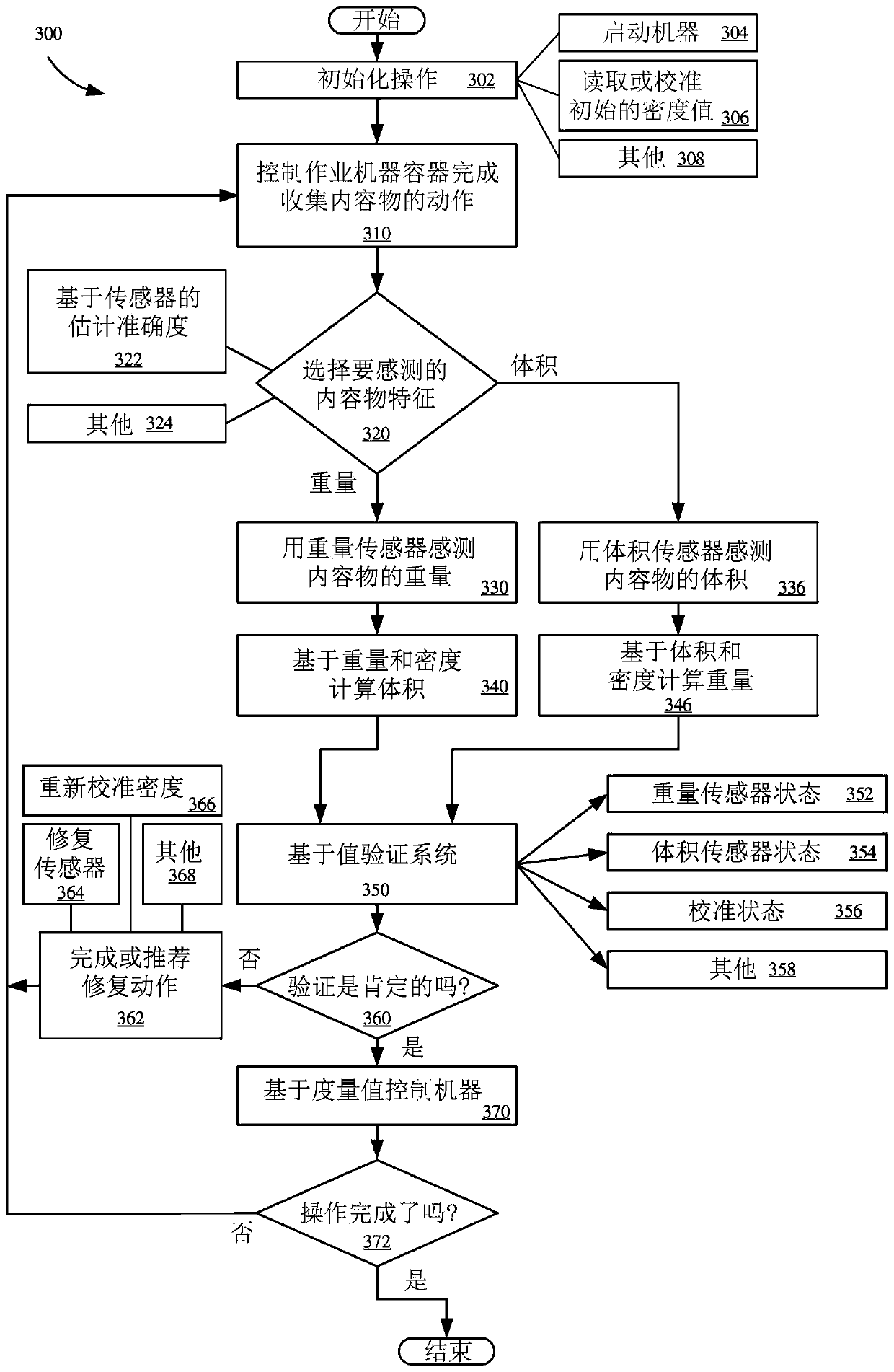

[0089] Embodiment 1 is a mobile work machine, which includes:

[0090] frame;

[0091] a ground engaging element movably supported by the frame and driven by a motor to drive movement of the mobile work machine;

[0092] a container movably supported by the frame, the container configured to receive contents;

[0093] an actuator configured to controllably drive movement of the container relative to the frame;

[0094] a control system configured to: generate an actuator control signal indicative of commanded movement of the actuator; and provide the actuator control signal to the actuator to control the actuator carry out said commanded movement; and

[0095] A content density determination system, communicatively coupled to the control system, is configured to determine the density of the contents of the container.

Embodiment 2

[0096] Embodiment 2 is the mobile work machine of Embodiment 1, further comprising:

[0097] a volume sensor configured to generate a volume sensor signal;

[0098] volume generator logic configured to determine the volume of the contents of the container based on the volume sensor signal; and

[0099] Wherein, the content density determination system determines the density based on the volume of the content.

Embodiment 3

[0100] Embodiment 3 is the mobile work machine of any or all of the preceding embodiments, further comprising:

[0101] a weight sensor configured to generate a weight sensor signal;

[0102] weight generator logic configured to determine the weight of the contents of the container based on the weight sensor signal; and

[0103] Wherein, the content density determination system determines the density based on the weight of the content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com