A soluble metal sealing fracturing bridge plug

A metal sealing and fracturing technology, which is applied in sealing/isolation, wellbore/well components, production fluids, etc., can solve the problem of poor temperature resistance and pressure resistance of soluble rubber barrel seals and inability to mass-produce soluble bridge plugs Application, complex structure of soluble bridge plugs, etc., to achieve uniform force, reduce the risk of problems, and uniform deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

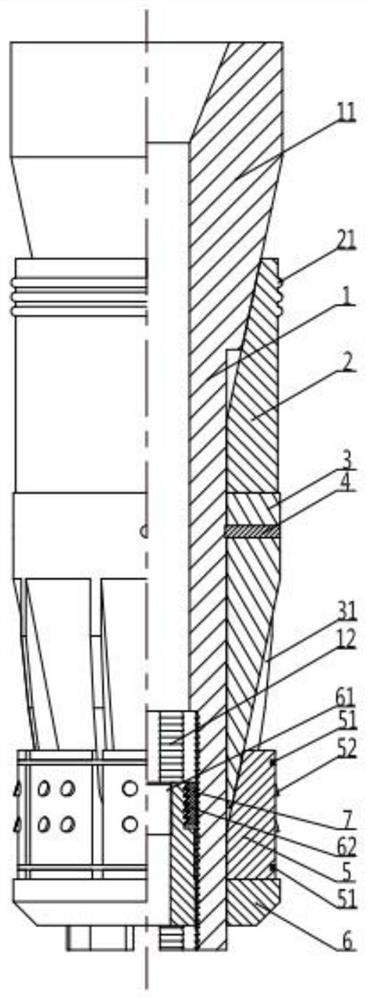

[0027] Below in conjunction with accompanying drawing and example, the present invention will be further described:

[0028] In the following description, when referring to the description of the working mode, the end close to the bottom of the well is the lower end, and the end close to the wellhead is the upper end. When it comes to the description of the structure of the bridge plug, the upper end is the direction in which the central support shaft 1 guides the circular table 11 , and the lower end is the direction of the sector-shaped insert rod 12 of the central supporting shaft 1 .

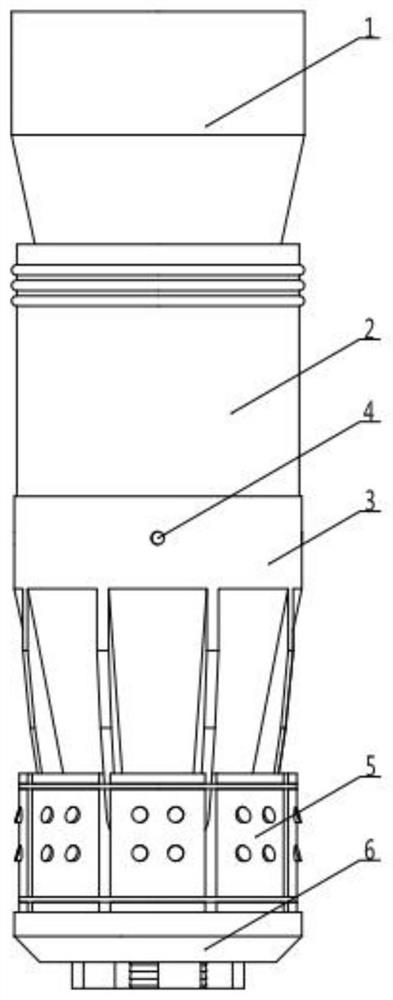

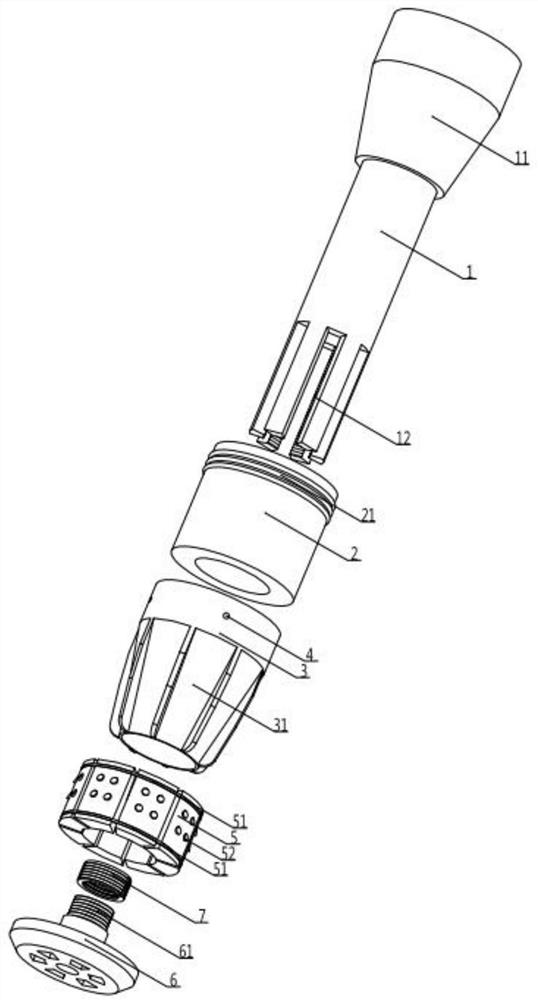

[0029] like Figure 1-Figure 8 As shown, a soluble metal sealing fracturing bridge plug of the present invention includes a central support shaft 1, a metal sealing sleeve 2, a wedge body 3, a safety pin 4, a slip assembly 5, a setting joint 6 and a locking ring 7, The central support shaft 1 is located at the uppermost part of the whole set of devices. The central support shaft 1 is made o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com