Anti-scouring packer

A packer and anti-scouring technology, which is applied in the direction of sealing/packing, wellbore/well components, earthwork drilling and production, etc., can solve problems such as poor anti-scouring ability, no anchoring device, and damage to the rubber tube, and achieve anti-scouring Strong flushing ability, long service life and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

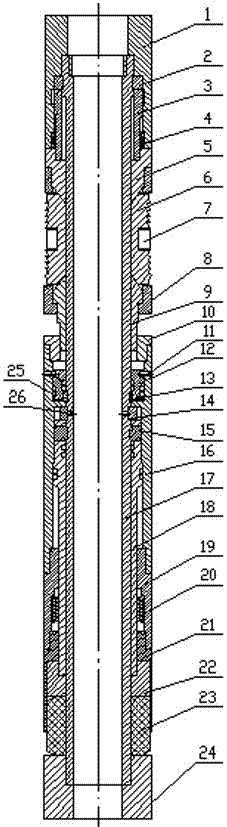

[0014] refer to figure 1 , an anti-scouring packer, including an unsealing joint 1, an unsealing ring 2, a connecting joint 3, a retaining ring 4, an upper cone 5, a slip 6, a spring leaf 7, a slip cover 8, and a lower cone 9 , upper pressure cap 10, setting pin 11, piston 12, upper limit ring 13, lower limit ring 14, lock block 15, hydraulic sleeve 16, main shaft 17, pressure transmission inner sleeve 18, pressure transmission sleeve 19, lock ring 20, Rubber sleeve protective cover 21, sliding joint 22, rubber sleeve 23 and lower joint 24. A main shaft 17 is installed and connected between the inside of the unsealing joint 1 and the inside of the lower joint 24, and the outside of the main shaft 17 is sequentially installed and connected with an unsealing ring 2, a connecting joint 3, an upper cone 5, slips 6, slip covers 8, Lower cone 9, upper pressure cap 10, piston 12, hydraulic sleeve 16, pressure transmission inner sleeve 18, pressure transmission sleeve 19, rubber slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com