An automatic packing device for casing

An isolation device and automatic technology, applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problems of inconvenient operation of isolation operation, complex structure of isolation device and high manufacturing cost, and achieve Avoid setting in advance, improve the sealing effect, and achieve high sealing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is introduced below by accompanying drawing.

[0024] In this application, the end of the automatic isolation device for casing running into the wellbore according to the present invention near the wellhead is defined as the upper end or similar terms, and the end away from the wellhead is defined as the lower end or similar terms.

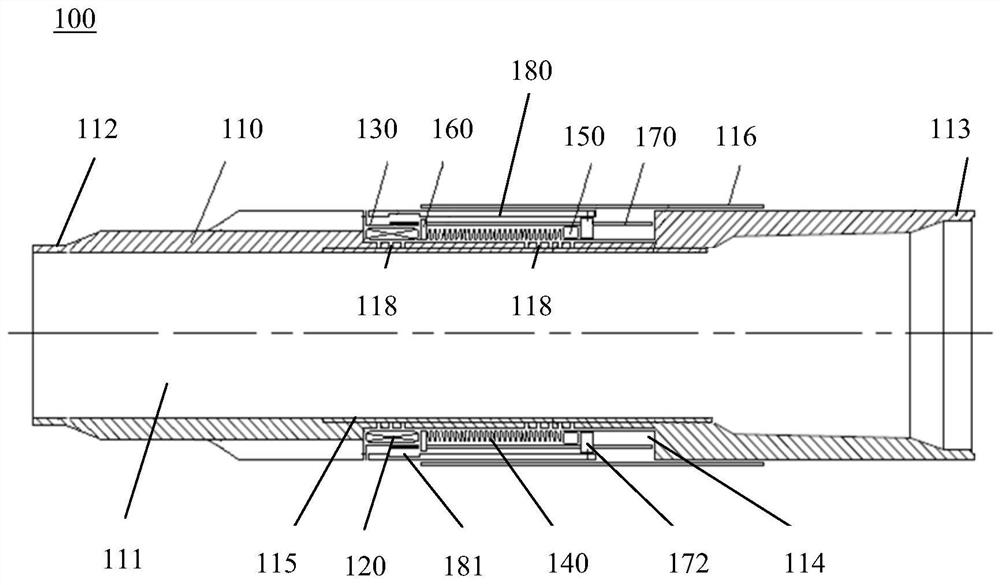

[0025] figure 1 The structure of the automatic isolation device 100 for casing according to the present invention is schematically shown. Such as figure 1 As shown, the automated containment device 100 includes a cylindrical body 110 . The main body 110 is provided with a central flow channel 111, and the central flow channel 111 is used for the fluid in the wellbore to flow therethrough. In one embodiment, the upper end of the body 110 is configured as a male snap joint 112 , and the lower end of the body 110 is configured as a female snap joint 113 . The body 110 is connected to other drilling tools through a pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com