Double-seal straddle formation testing method

A formation testing and spanning technology, which is applied in the field of downhole testing equipment and double-sealing spanning formation testing, can solve the problems of low test efficiency, many procedures and long time, and achieves the improvement of test efficiency, shortening procedures and avoiding pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The method for testing double-sealed straddle formations of the present invention comprises the following steps in turn: (1) perforating the first test well section to communicate the first formation with the casing;

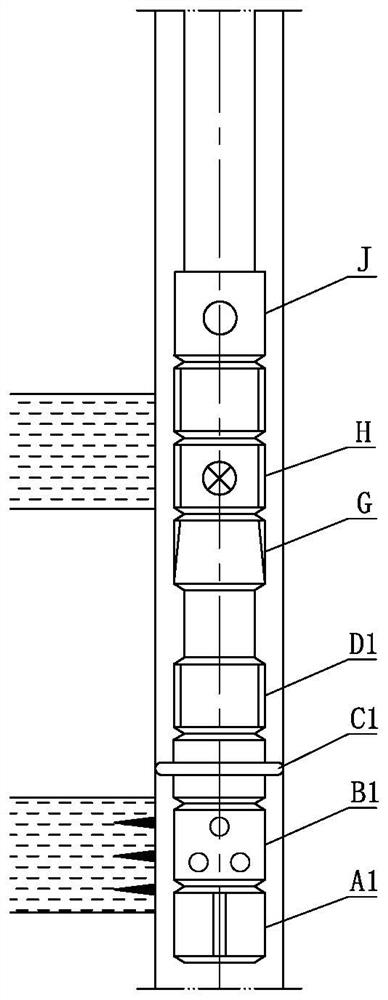

[0044] ⑵The single-sealed test string is assembled into the well, such as figure 1 As shown, the single-seal test string includes pressure gauge holder A1, screen pipe B1, slip packer C1, mechanical lock G, tester H and circulation valve J from bottom to top;

[0045] (3) The single-sealed test string is pulled out after completing the test of the first test section;

[0046] (4) Perforating the second test section to connect the second formation with the inside of the casing;

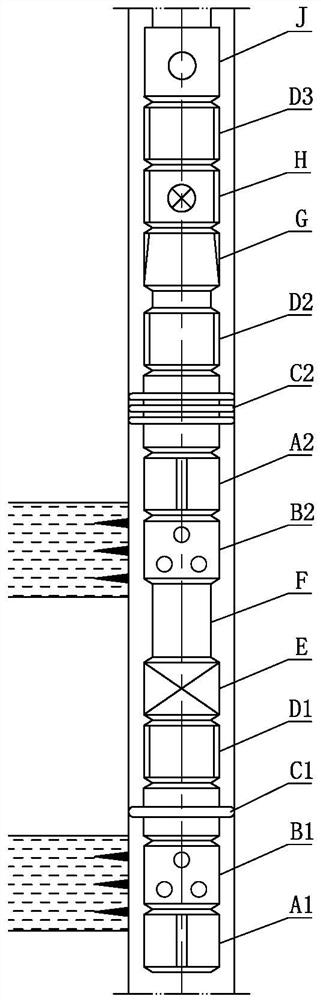

[0047] ⑸Double-sealed spanning test string is assembled into the well, such as figure 2 As shown, the double-seal straddle test string includes pressure gauge holder A1, screen pipe B1, slip packer C1, lifting nipple D1, plug E, adjusting nipple F, Screen tube 2 B2, pressure g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com