Explosion-proof device of vacuum heat insulation container

An explosion-proof device and vacuum insulation technology, applied in pressure vessels, container filling methods, container discharge methods, etc., can solve the problems of low safety, lost workers, short vacuum life maintenance time, etc., to improve the sealing effect and meet the needs of use. Demand, design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

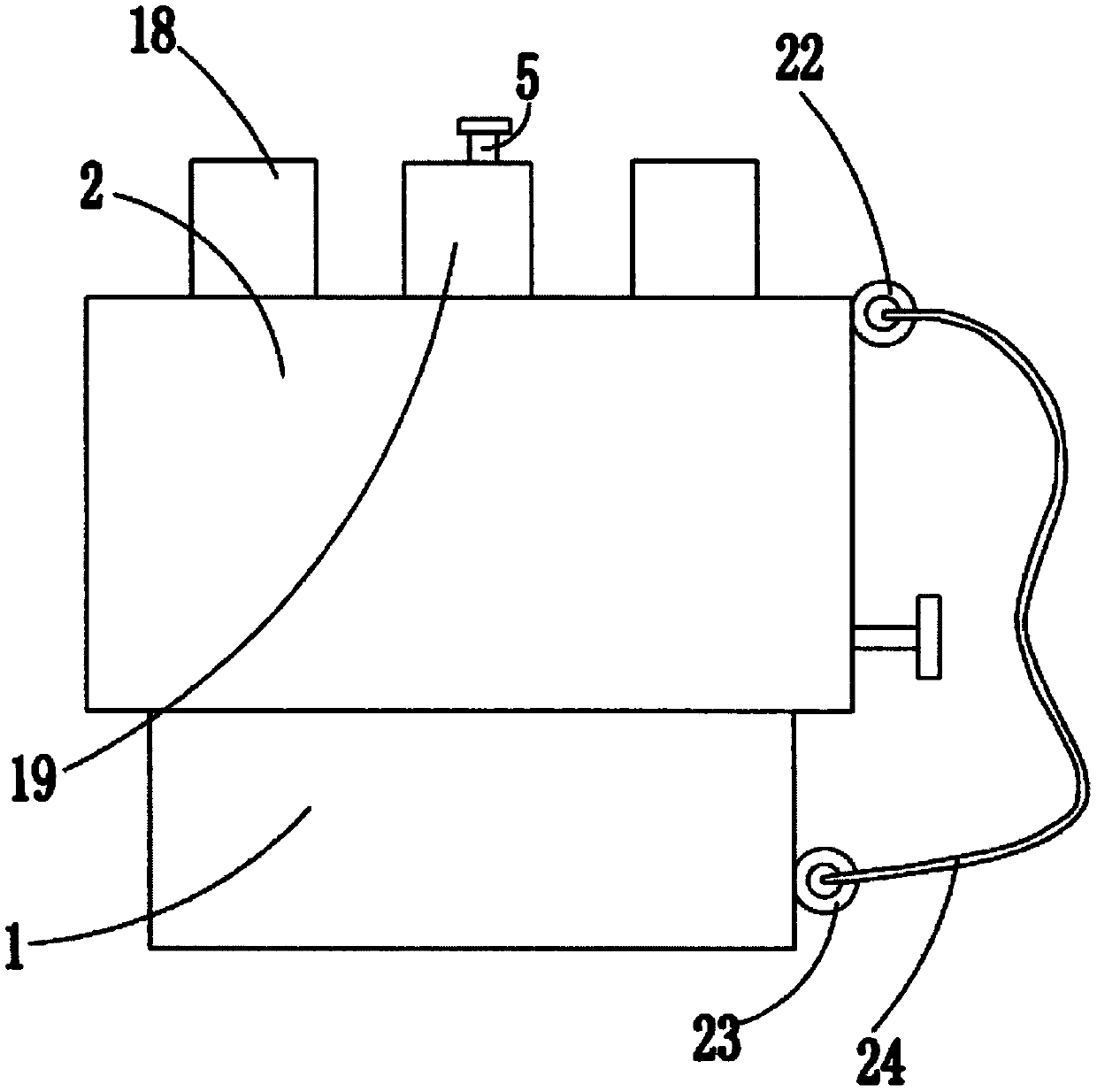

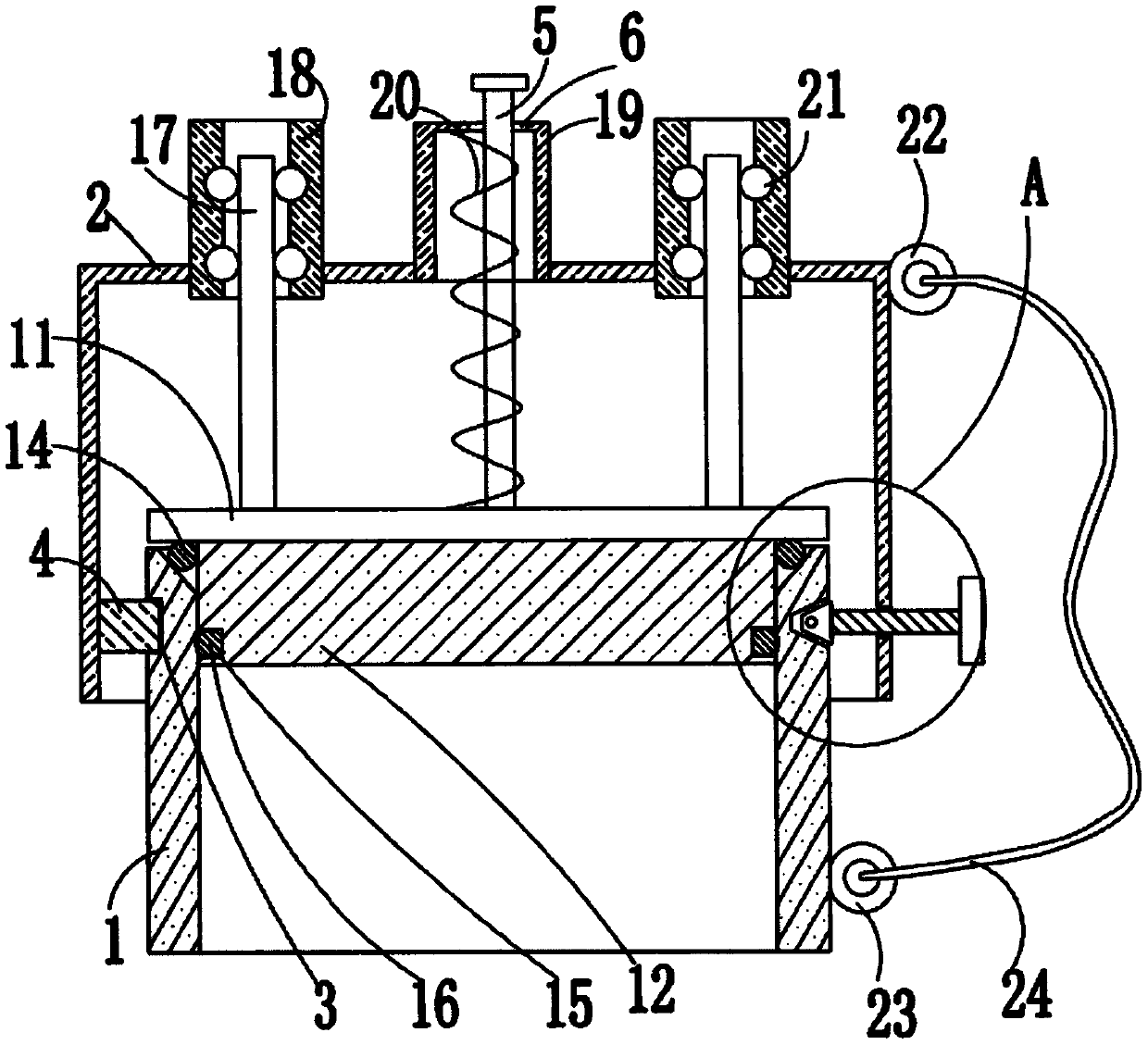

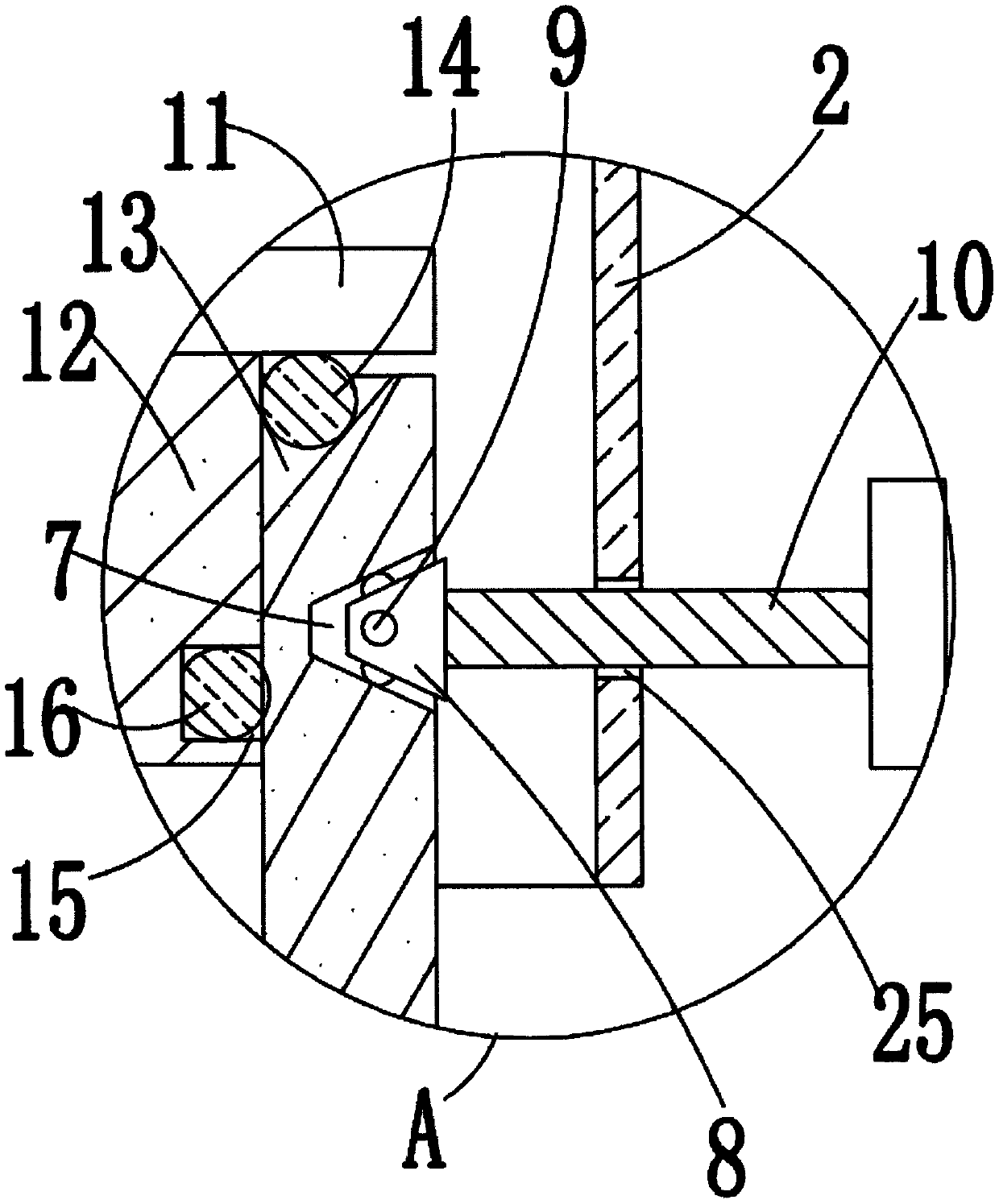

[0025] refer to Figure 1-5 , this embodiment proposes an explosion-proof device for a vacuum heat-insulated container, including an explosion-proof cylinder 1, a block 12 is set in a movable seal in the explosion-proof cylinder 1, and the top of the block 12 extends to the top of the explosion-proof cylinder 1 and is fixed. The upper cover 11 is connected, the explosion-proof cylinder 1 is covered with a protective cover 2, the top of one side of the explosion-proof cylinder 1 is provided with a rectangular groove 3, and the inner wall of one side of the protective cover 2 is fixedly connected with a rectangular block 4, a rectangular block 4 Fitted with the rectangular groove 3 movably, the top of the other side of the explosion-proof cylinder 1 is provided with a first frustum-shaped groove 7, and a frustum-shaped block 8 is arranged in the first frustum-shaped groove 7, and the outer side of the frustum-shaped block 8 is annularly embedded. A plurality of first balls 9 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com