Camera detection method

A detection method and camera technology, which is applied in the field of camera detection, can solve problems such as the inability to sieve good products and defective products, lack of efficient and reliable camera defective product detection methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

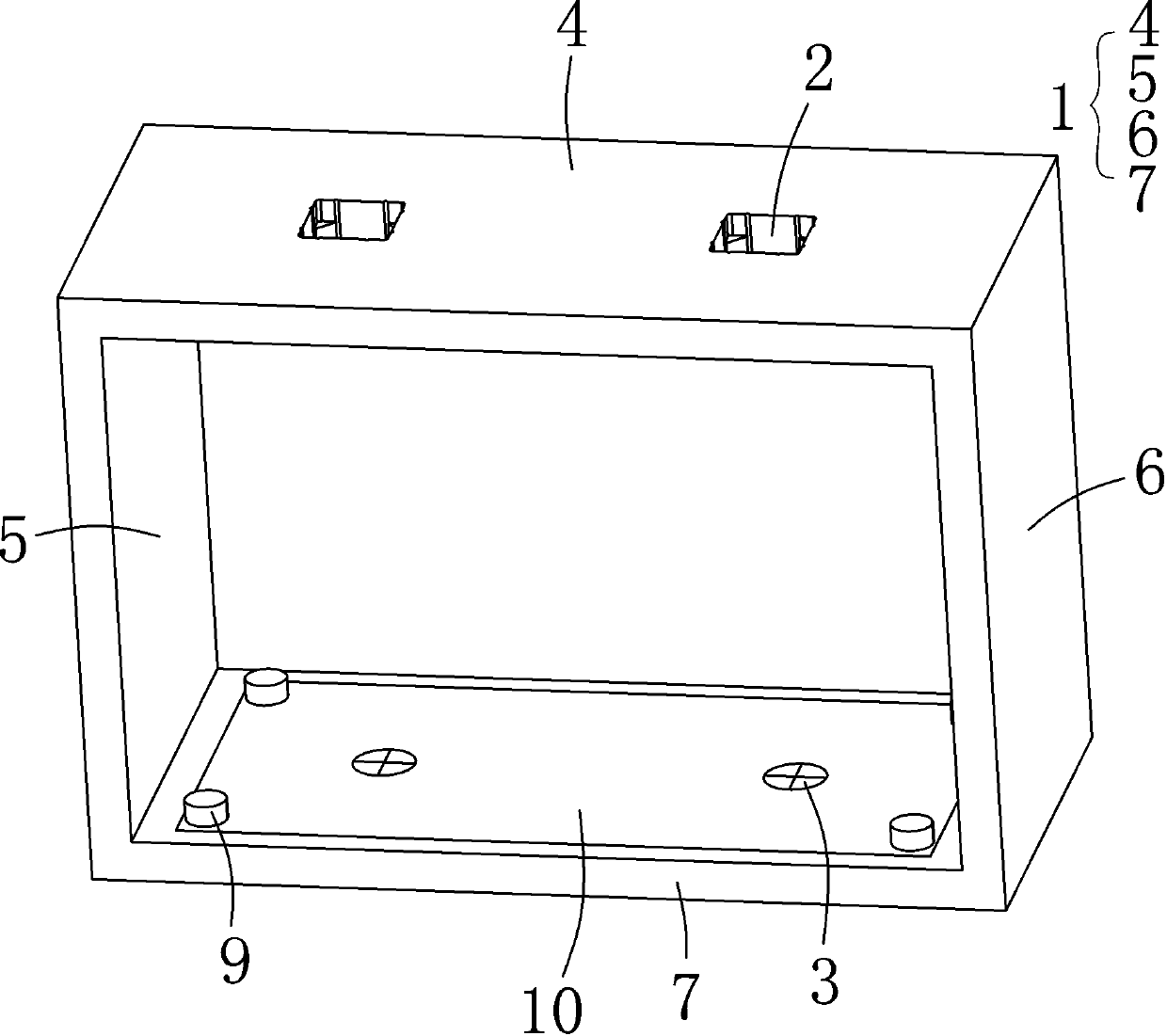

[0027] Please refer to Figure 1-3 , Embodiment 1 of the present invention includes:

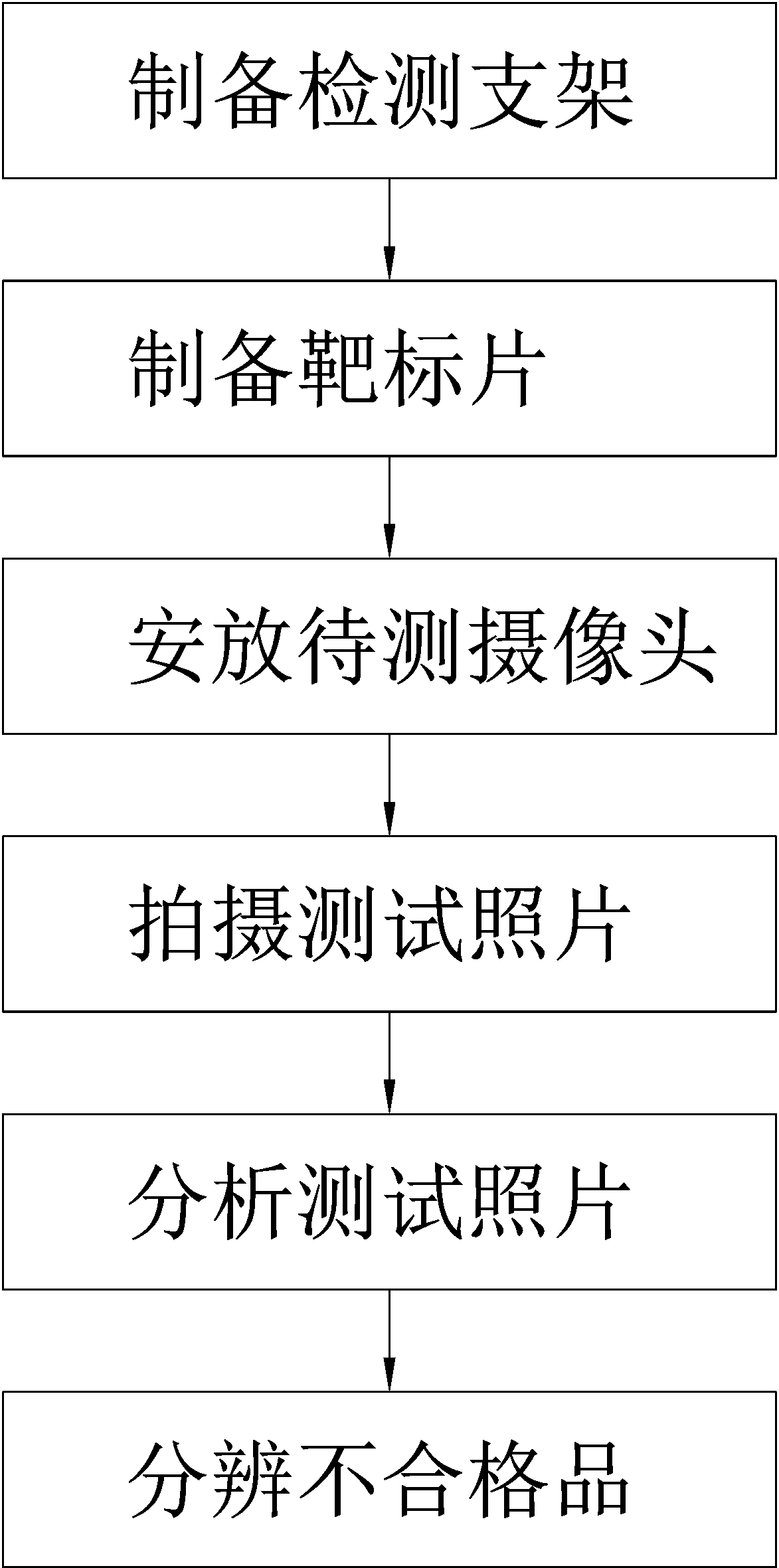

[0028] A camera detection method, comprising the steps of:

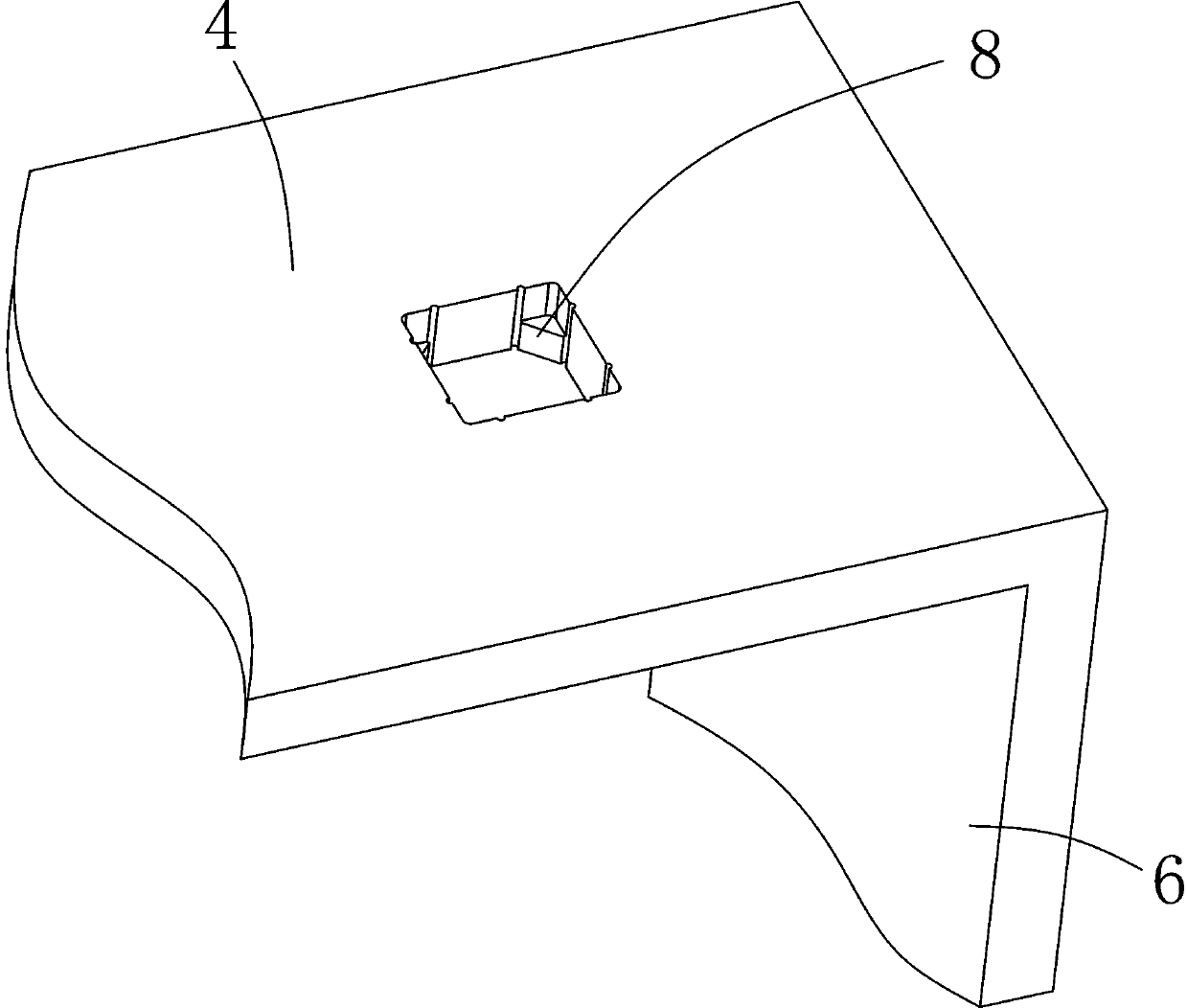

[0029] Step 1. Prepare the detection bracket. The upper part of the bracket is a fixed position for fixing the camera to be tested, and the lower part of the bracket is a workbench. The camera to be tested fixed at the fixed position can take pictures of the workbench; the detection bracket 1 includes a top plate 4 and a side plate-5 , side plate 2 6 and bottom plate 7; the fixing position is to dig the mounting hole 2 located at the top plate 4, the target 3 faces the mounting hole 2, the lens of the camera placed on the mounting hole 2 faces the target 3, and the mounting hole 2 runs through the top plate 4 , The inner wall of the mounting hole 2 is also provided with a block 8 .

[0030] Step 2. Prepare the target sheet, select the sheet as the target sheet, and draw or paste the target on the surface of the target sheet. The ...

Embodiment 2

[0036] Embodiment 2 of the present invention includes:

[0037] A camera detection method, comprising the steps of:

[0038] Step 1. Prepare the detection bracket. The upper part of the bracket is the fixed position for fixing the camera to be tested, and the lower part of the bracket is the workbench. The camera to be tested fixed at the fixed position can take pictures of the workbench; the detection bracket includes top plate, side plate 1, and side plate Erhe bottom plate; the fixed position is to dig the mounting hole located on the top plate, the target faces the mounting hole, the lens of the camera placed on the mounting hole faces the target, the mounting hole runs through the top plate, and the inner wall of the mounting hole is also provided with a block.

[0039] Step 2. Prepare the target sheet, select the sheet as the target sheet, and draw or paste the target on the surface of the target sheet. The target has an outer circle and a cross-shaped intersection locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com