Distribution network line fault detection method based on integrated distribution box and high-voltage sensor

A high-voltage sensor, line fault technology, applied in the field of power distribution automation, can solve the problems of low ground fault detection accuracy, fault indicator products cannot achieve accurate on-site judgment of single-phase ground faults, etc., so as to reduce the access burden. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

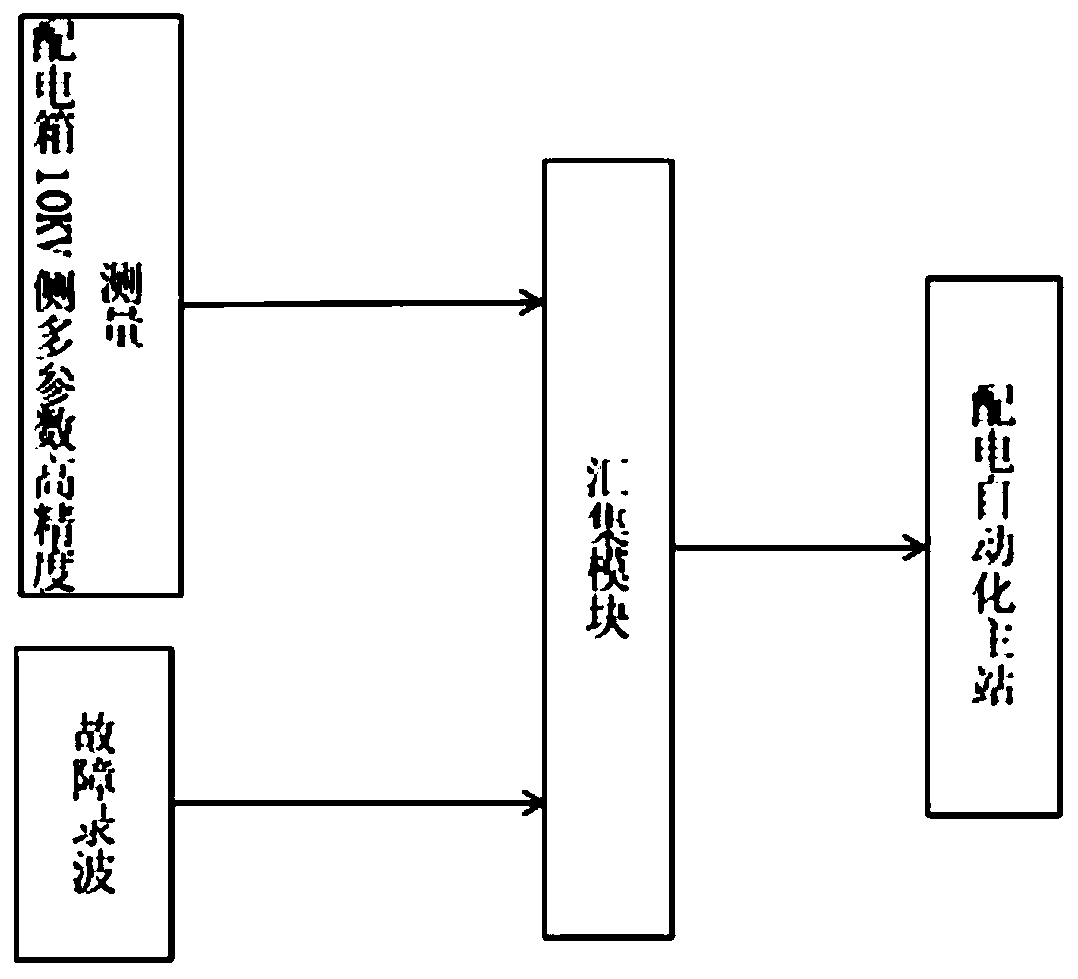

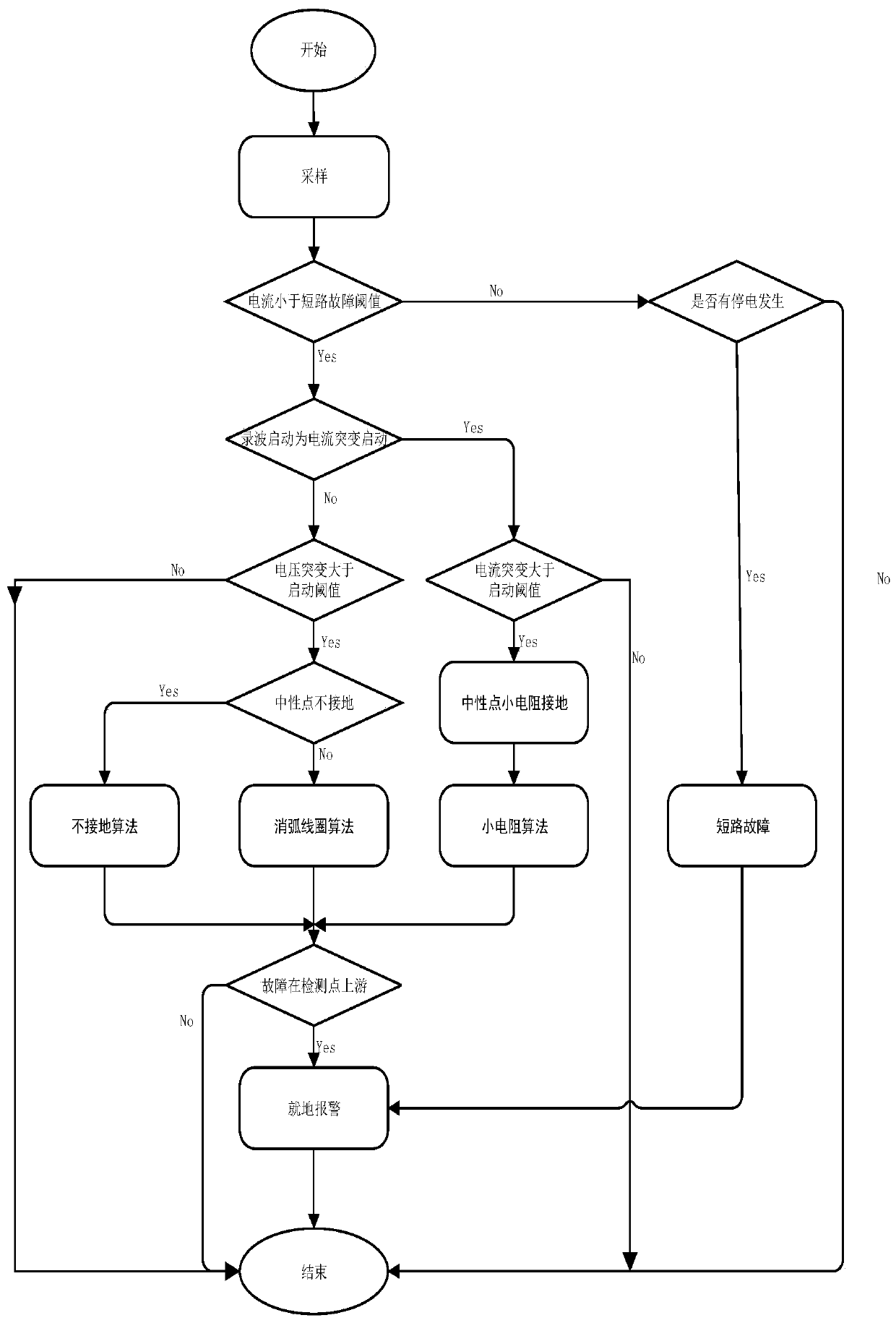

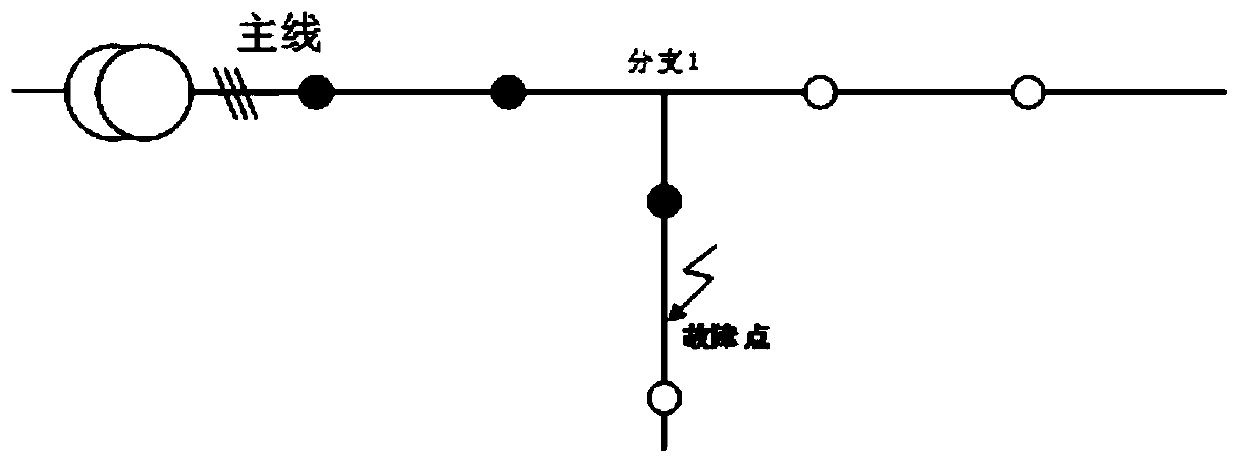

[0031] A distribution network line fault detection method based on an integrated distribution box and a high-voltage sensor, comprising:

[0032] Step 1. Install the sensor on the A, B and C phases of the corresponding line, and use wireless transmission to transmit the collected data to the collection module;

[0033] Step 2. The collection module is responsible for calculating the three-phase sensor data, judging the fault type and fault point section of the actual line on the spot, and the collection module transmits the final calculation result or line parameters to the integrated distribution box in real time through wireless transmission;

[0034] Step 3. The integrated distribution box wirelessly transmits the calculation results or line parameters to the master station.

[0035] The sensor is a bolt structure.

[0036] The collection module is installed in the integrated distribution box: the collection module is connected to the integrated distribution box controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com