Cutter clamping structure of tool changing mechanism

A technology of clamping structure and tool changing mechanism, which can be used in clamping, manufacturing tools, metal processing mechanical parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

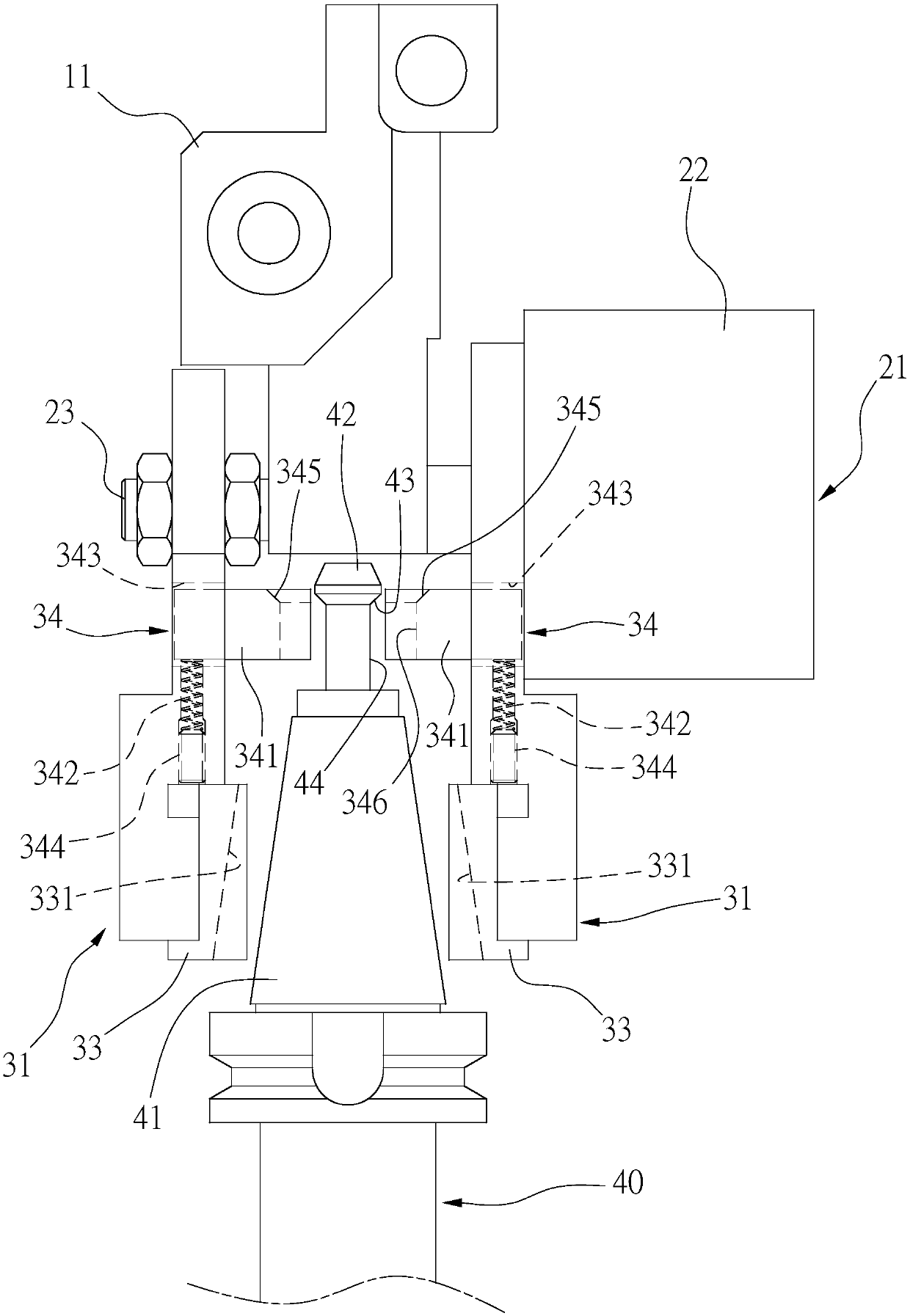

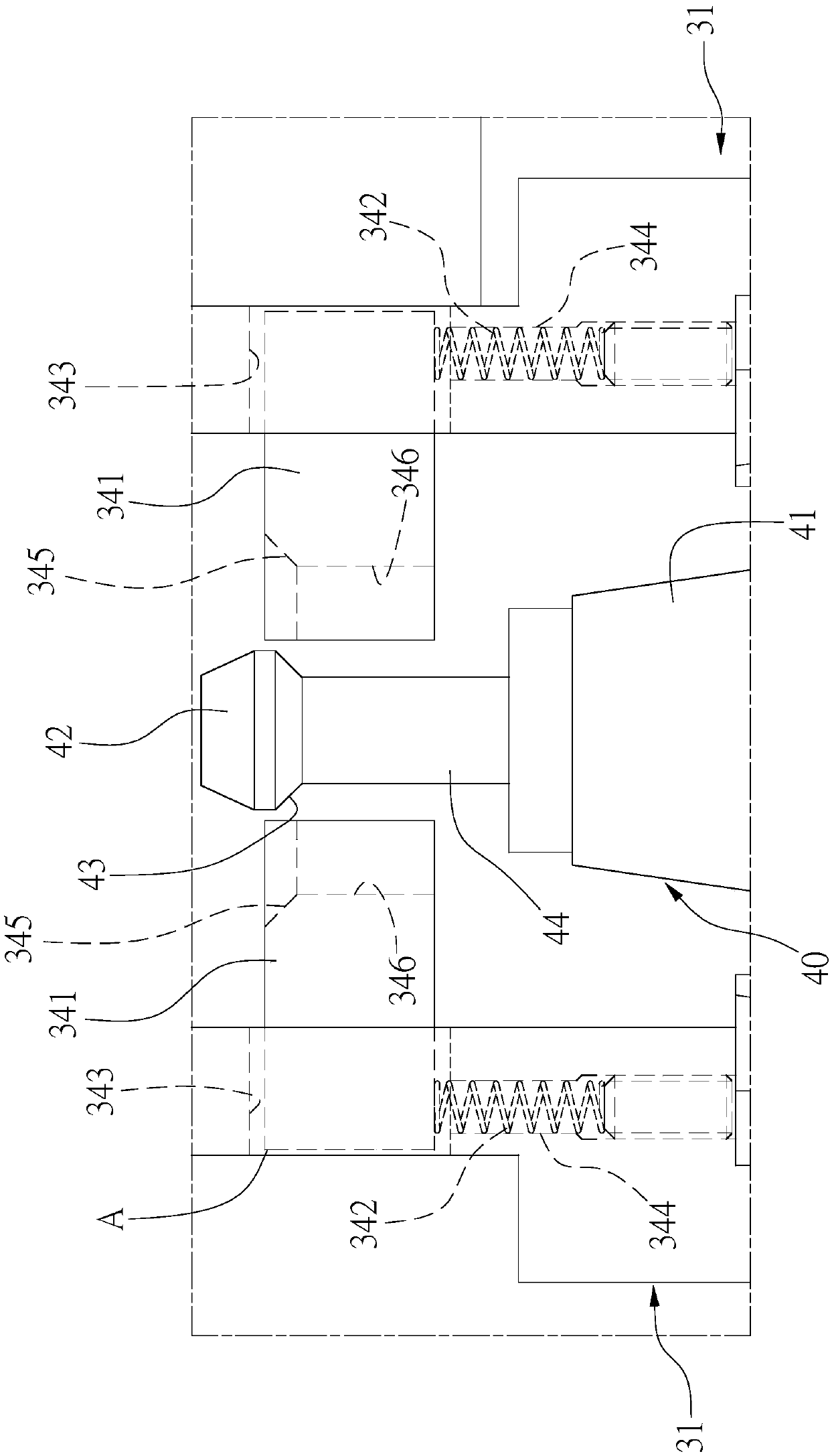

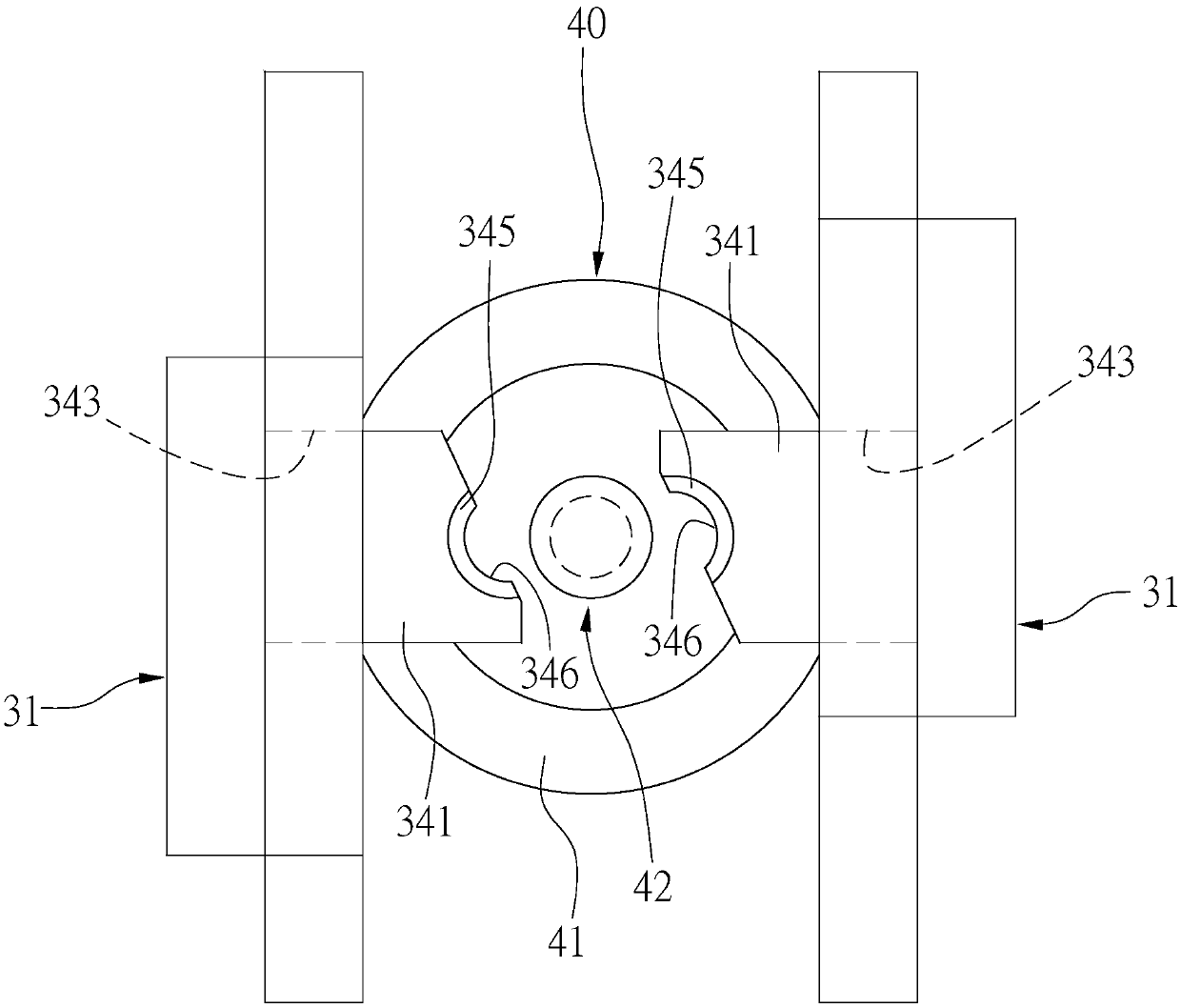

[0022] see Figure 1 to Figure 6 , those shown in the figure are preferred embodiments selected by the present invention, which are for illustration purposes only, and are not limited by the embodiments in the patent application.

[0023] Such as Figure 1 to Figure 3 As shown, the present invention provides a tool clamping structure, which is mainly composed of a set of seat body 11, a driving mechanism 21 and two clamping arms 31 arranged on the tool changing mechanism, wherein:

[0024] The driving mechanism 21 is disposed on the base body 11 , and the driving mechanism 21 is composed of a driving unit 22 and at least one telescopic rod 23 .

[0025] Two clamping arms 31, which are combined on the telescopic rod 23, and can drive the telescopic rod 23 to drive the clamping arm 31 through the drive unit 22, so that the two clamping arms 31 can move toward each other and are in a clamping position A The two clamping arms 31 have a first clamping portion 33 and a second clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com