Moveable blade for lever type plate shearing machine

The technology of a shearing machine and a moving blade is applied to the cutting tools, shearing devices, metal processing equipment and other directions of the shearing machine device, which can solve the problems of poor safety, easy to bite the moving blade, and the material to be cut hurts people. , to achieve the effect of stable feeding, reliable grasping and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

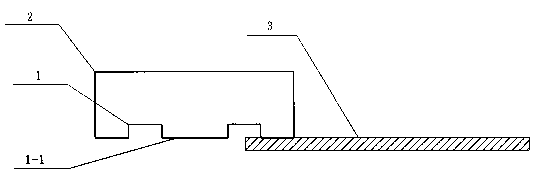

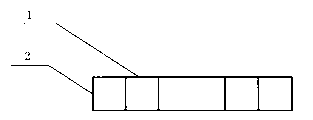

[0014] like figure 1 and figure 2 As shown, a movable blade for a lever type shearing machine is composed of a blade body 1 with a knife edge 1-1 at one end, and a groove 2 is opened on the blade body 1, and two grooves 2 are provided.

[0015] When the present invention is used, as figure 1 As shown, the material 3 to be cut is pushed from one side of the blade body 1 into between the movable blade of the lever shearing machine and the matching fixed blade, and after being cut by the movable blade and the fixed blade, the cut is completed. The material is pulled out from the other side of the blade body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com