Guide-post-free mold

A mold and guide post technology, applied in the field of non-guide post molds, can solve the problems of shortening the service life of the mold, reducing the positioning accuracy of the mold, increasing the cost of the mold, etc., to improve the precision and life, reduce the external size, and stabilize the production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

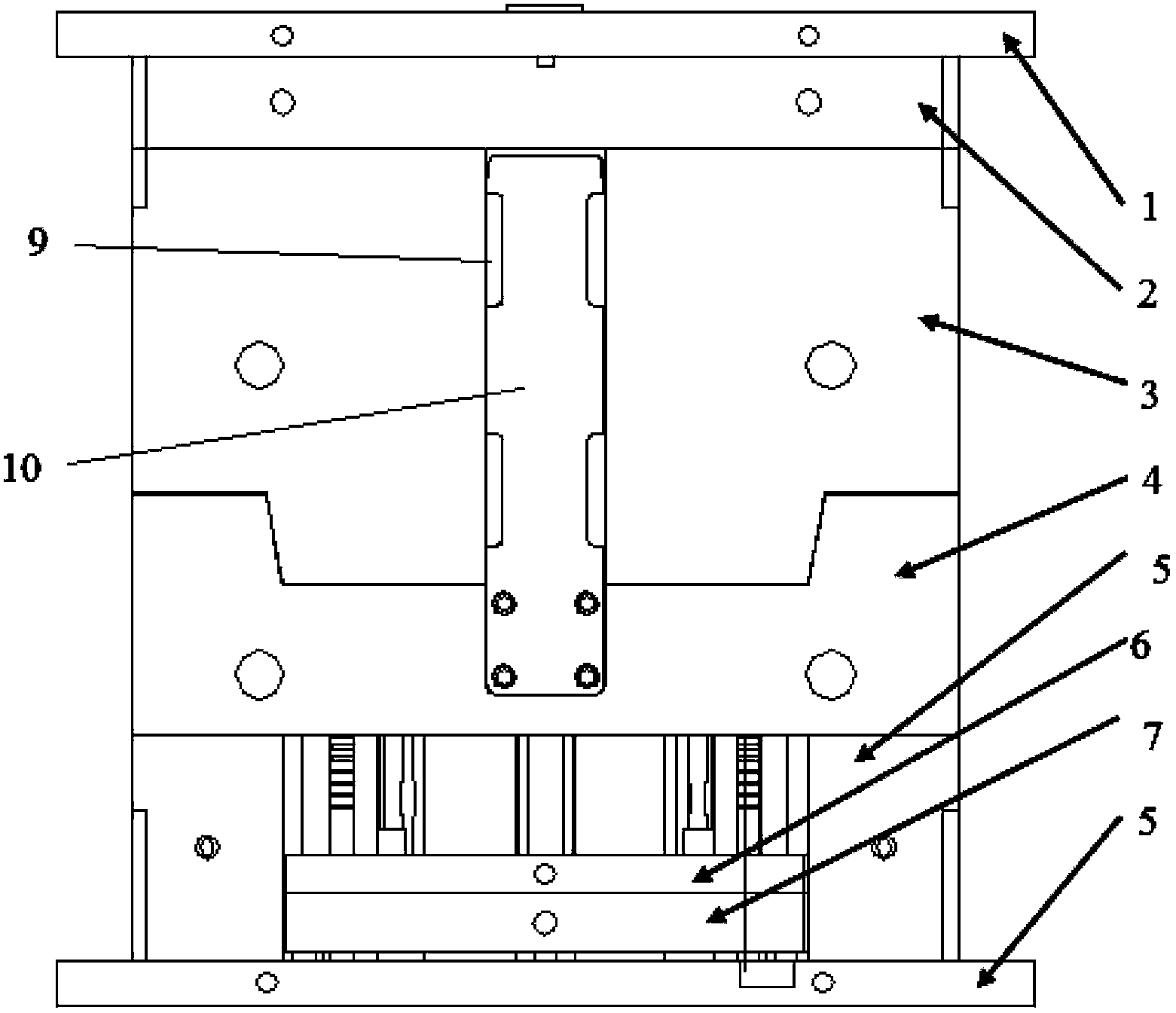

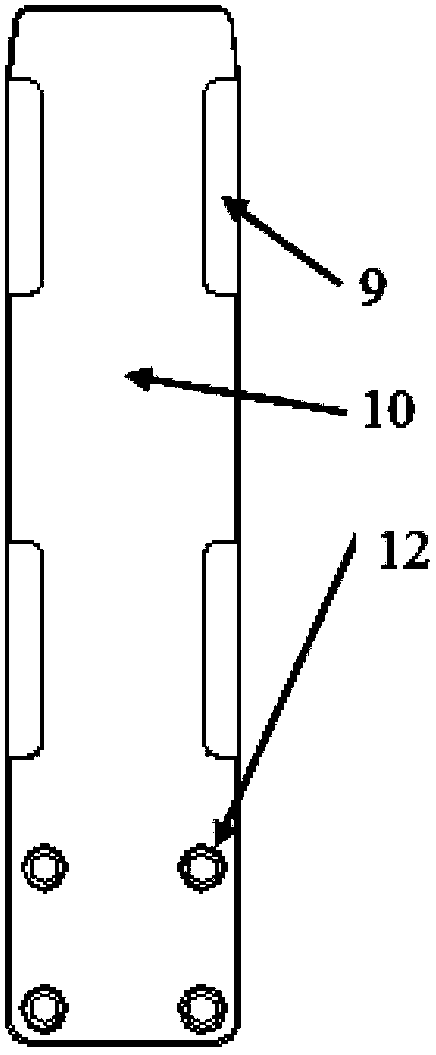

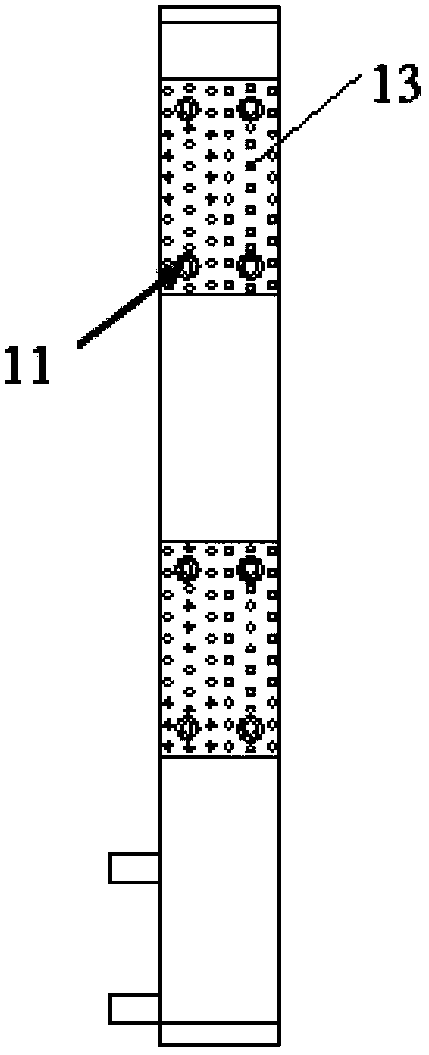

[0021] Such as Figure 1-3 As shown, a mold without guide pillars includes A plate 3 and B plate 4, the top of A plate 3 is fixed on the I-shaped plate 1 through the splitter plate 2 to form an upper mold, and the lower mold includes B plate 4, square iron 5, bottom plate 8. The face needle plate 6 and the bottom needle plate 7, and the B plate 4 are fixed on the bottom plate 8 through the square iron 5 arranged under the four corners of the bottom, and the bottom needle plate 7 and the face needle are arranged in turn between the bottom plate 8 and the B plate 4 board6.

[0022] The B plate 4 is square, and its surrounding sides are respectively provided with a positioning in-line block 10, the in-line block 10 is a positioning square iron, and the material is a carburized SUJ2 iron block, and its lower end is fixed on the B plate by a screw M2012 4, the upper end extends upwards, and the extended length matches the height of the A plate 3; each in-line block 10 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com