Fixing mechanism for mounting of toilet lid seat ring

A fixing mechanism and installation technology, used in workpiece clamping devices, manufacturing tools, etc., can solve problems such as scratches, affect appearance, surface scratches, etc., and achieve the effect of reducing scratches, reducing friction, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

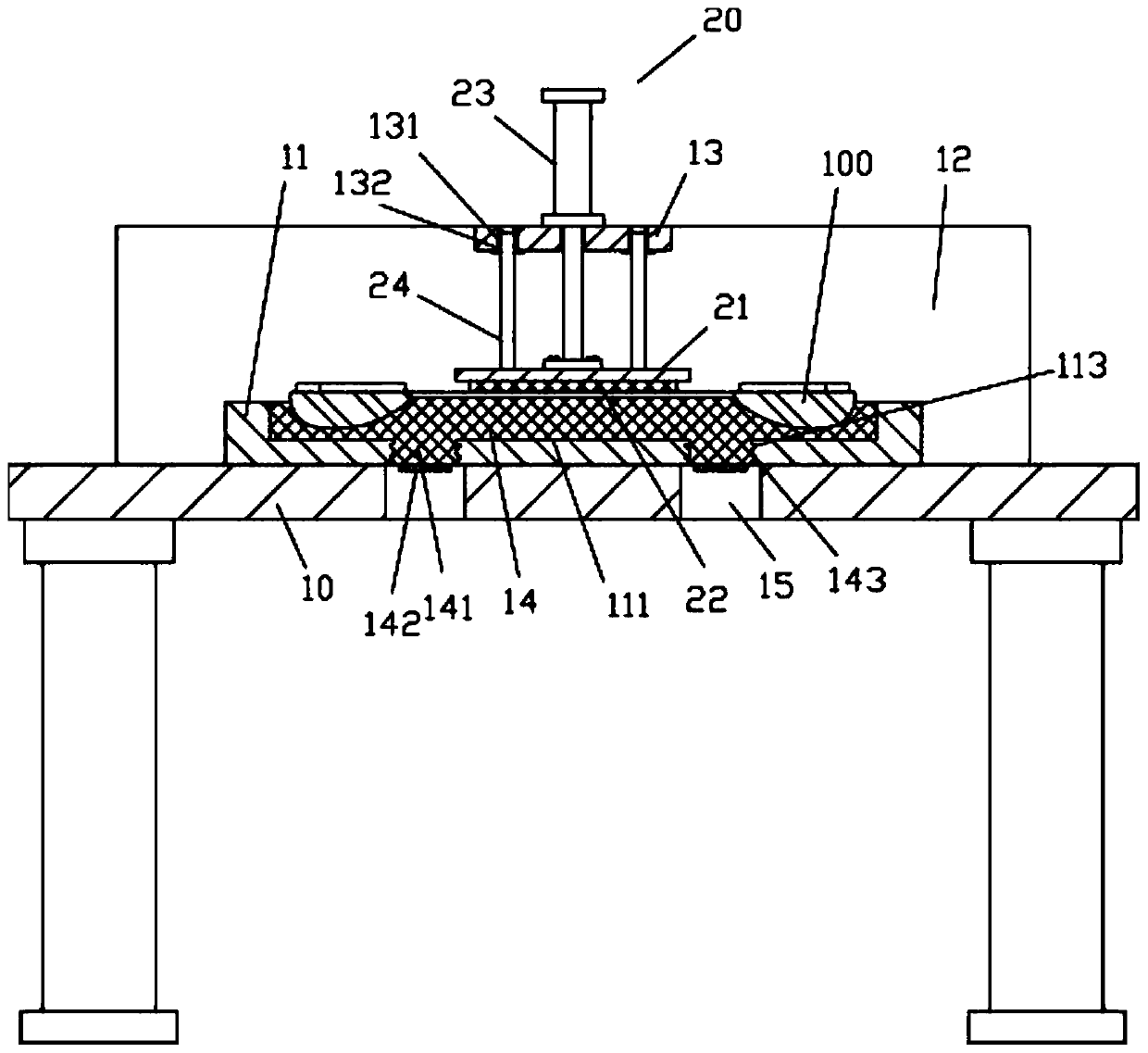

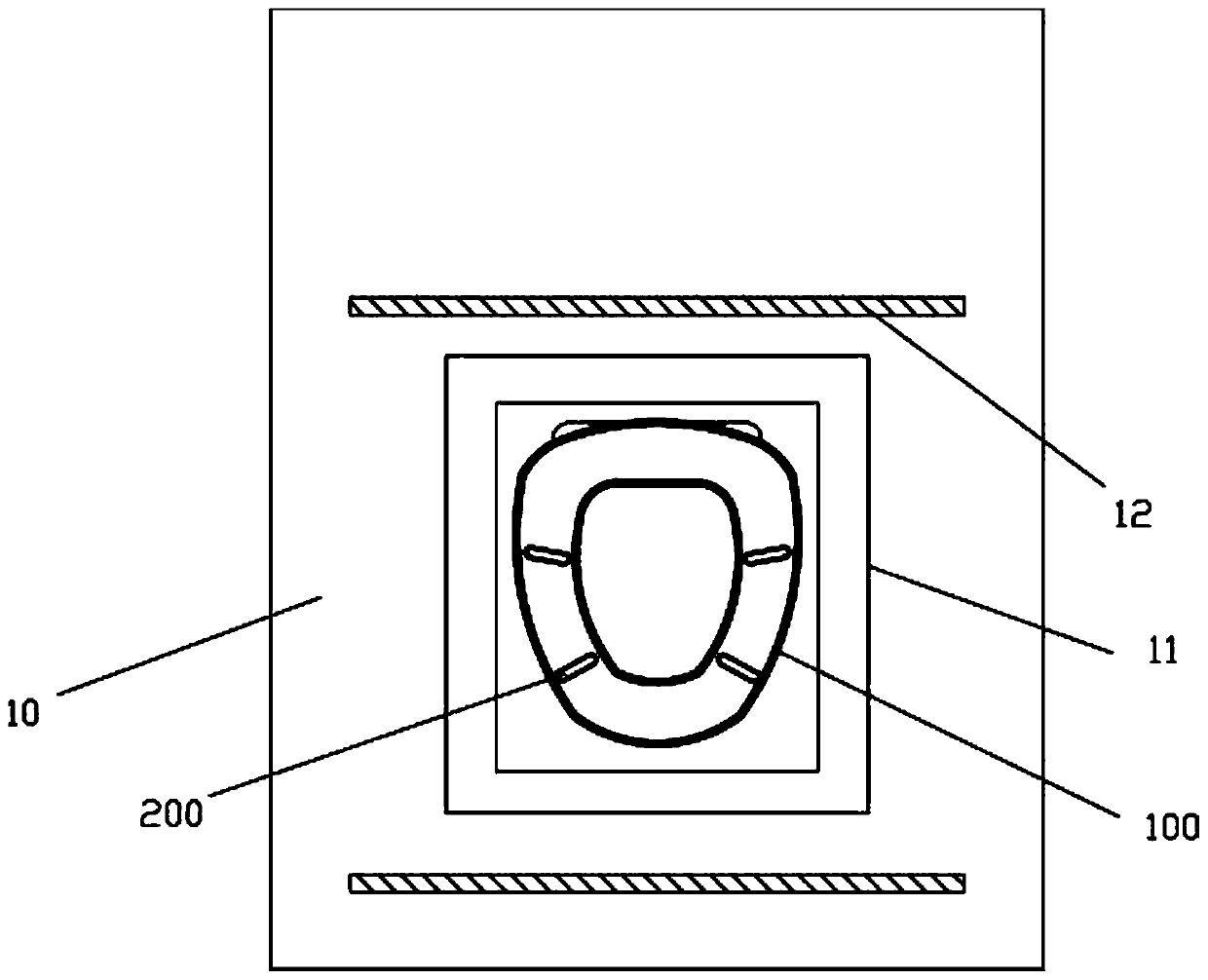

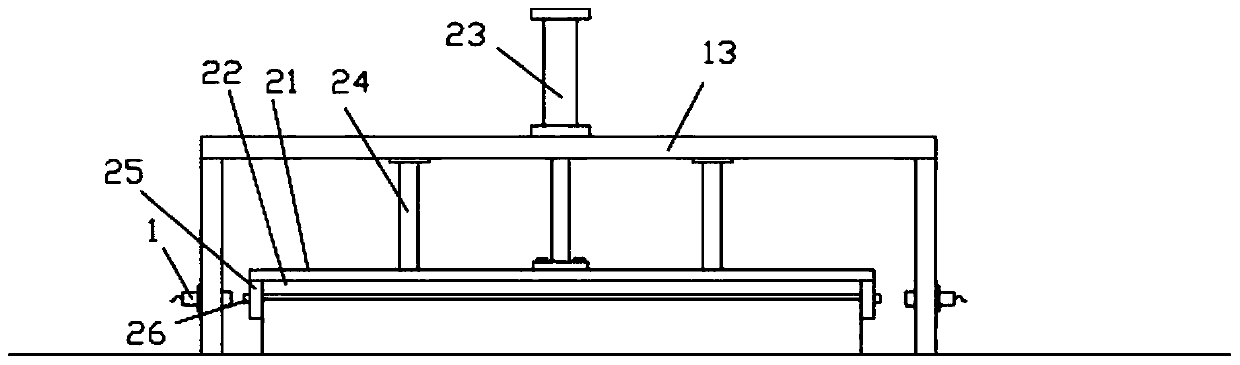

[0023] Examples, see e.g. Figure 1 to Figure 4 As shown, a fixing mechanism for installing a toilet lid seat includes an installation platform frame 10, the middle part of the top surface of the installation platform frame 10 is fixed with a connecting block 11, and the middle part of the top surface of the connecting block 11 is provided with a mounting groove 111 , the toilet seat 100 to be installed is placed upside down in the installation groove 111;

[0024] A supporting connecting plate 12 is fixed on the top surface of the installation platform frame 10 at the front and rear of the placing connecting block 11, and the middle transverse beam 13 is fixed on the top of the two supporting connecting plates 12.

[0025] On the surface, a pressing mechanism 20 is fixed on the middle transverse beam 13, and the pressing plate 21 of the pressing mechanism 20 presses against the top surface of the toilet seat 100 to be installed.

[0026] Furthermore, an elastic silicone pad ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap