Batch silkworm cocoon removing machine for silk processing

A cocoon removing machine and silkworm cocoon technology, applied in mechanical processing, silk fiber production, textiles and papermaking, etc., can solve the problems of cocoon picking, time-consuming, low efficiency, etc., and achieve the effect of convenient collection and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

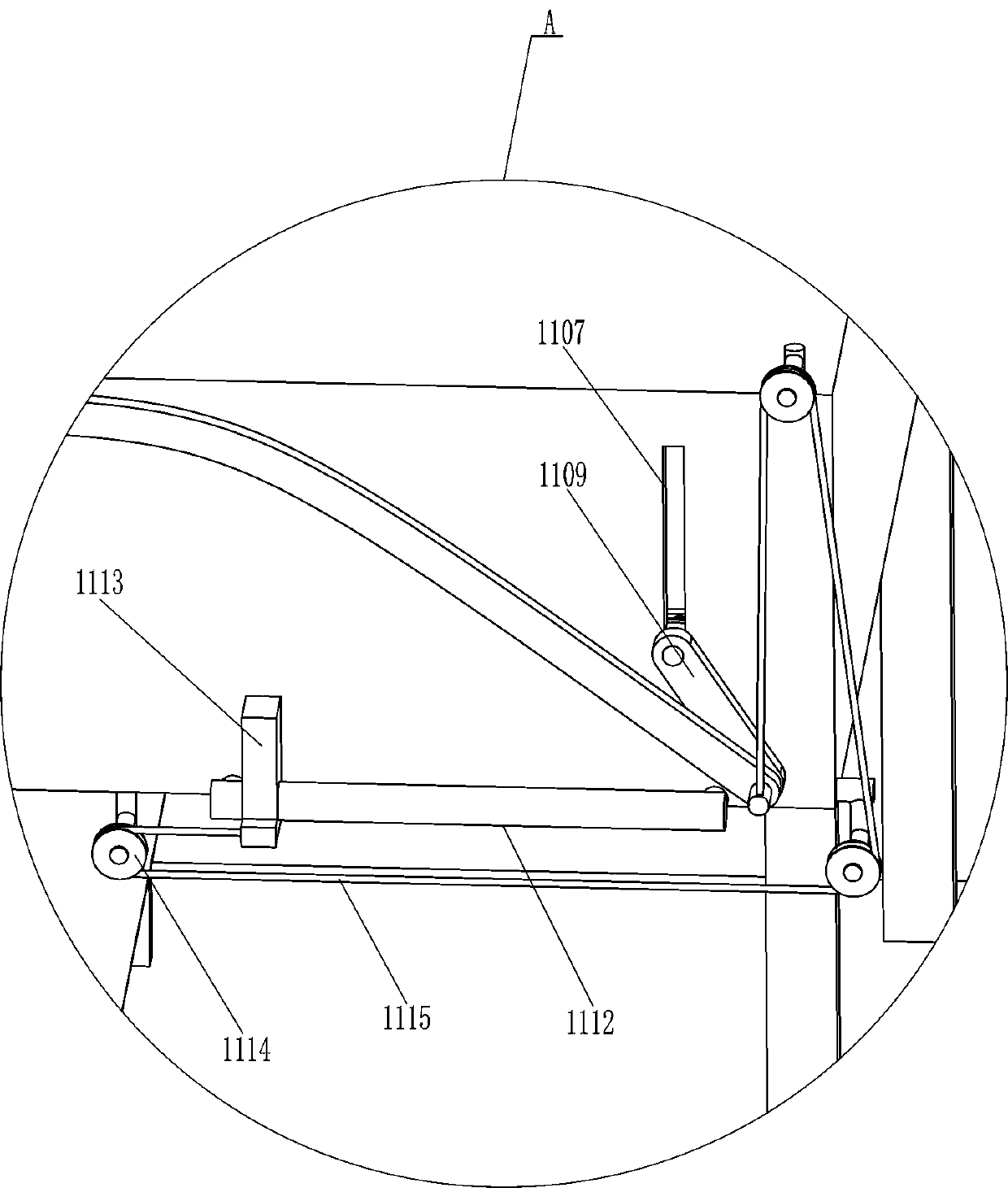

[0026] A batch cocoon removal machine for silk processing, as attached figure 1 , figure 2 , image 3 , Figure 4 and Figure 7 As shown, it includes a bottom plate 1, a first bracket 2, a frame body 3, a guide sleeve 4, a first support rod 5, a first push block 6, a support sleeve 7, a placement frame 8, a handle 9, a first spring 10 and a release Cocoon assembly 11, two first brackets 2 are installed on the left and right sides of the top of the bottom plate 1 through bolts, the tops of the four first brackets 2 are installed with a frame body 3 through bolts, and guide sleeves are installed on the front and rear sides of the left part of the frame body 3 4. The first support rods 5 are slidingly provided in the two guide sleeves 4, the first push block 6 is connected to the right ends of the two first support rods 5, and the two first support rods 5 are slidingly provided with supports Cover 7, a placement frame 8 is connected between the two support sleeves 7 through ...

Embodiment 2

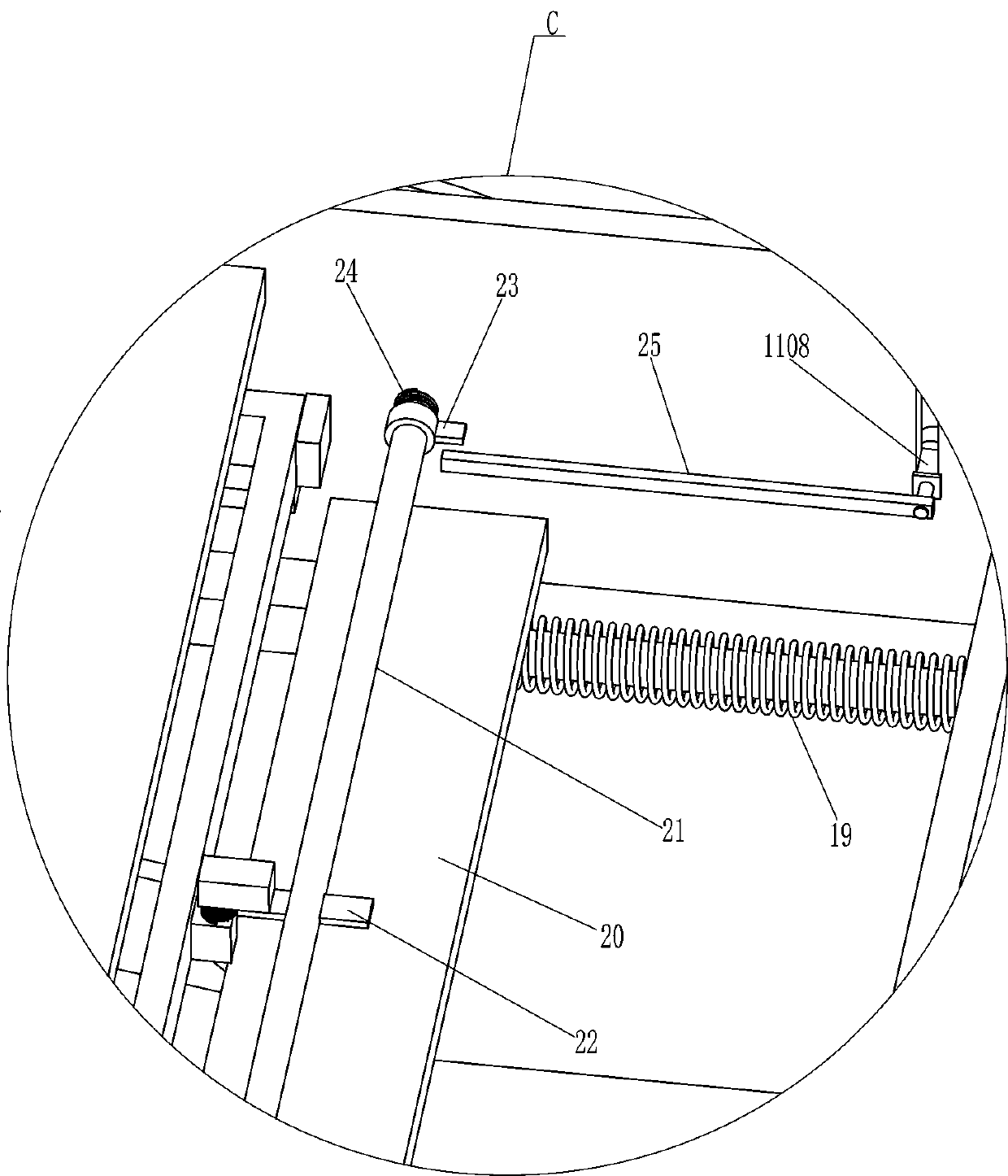

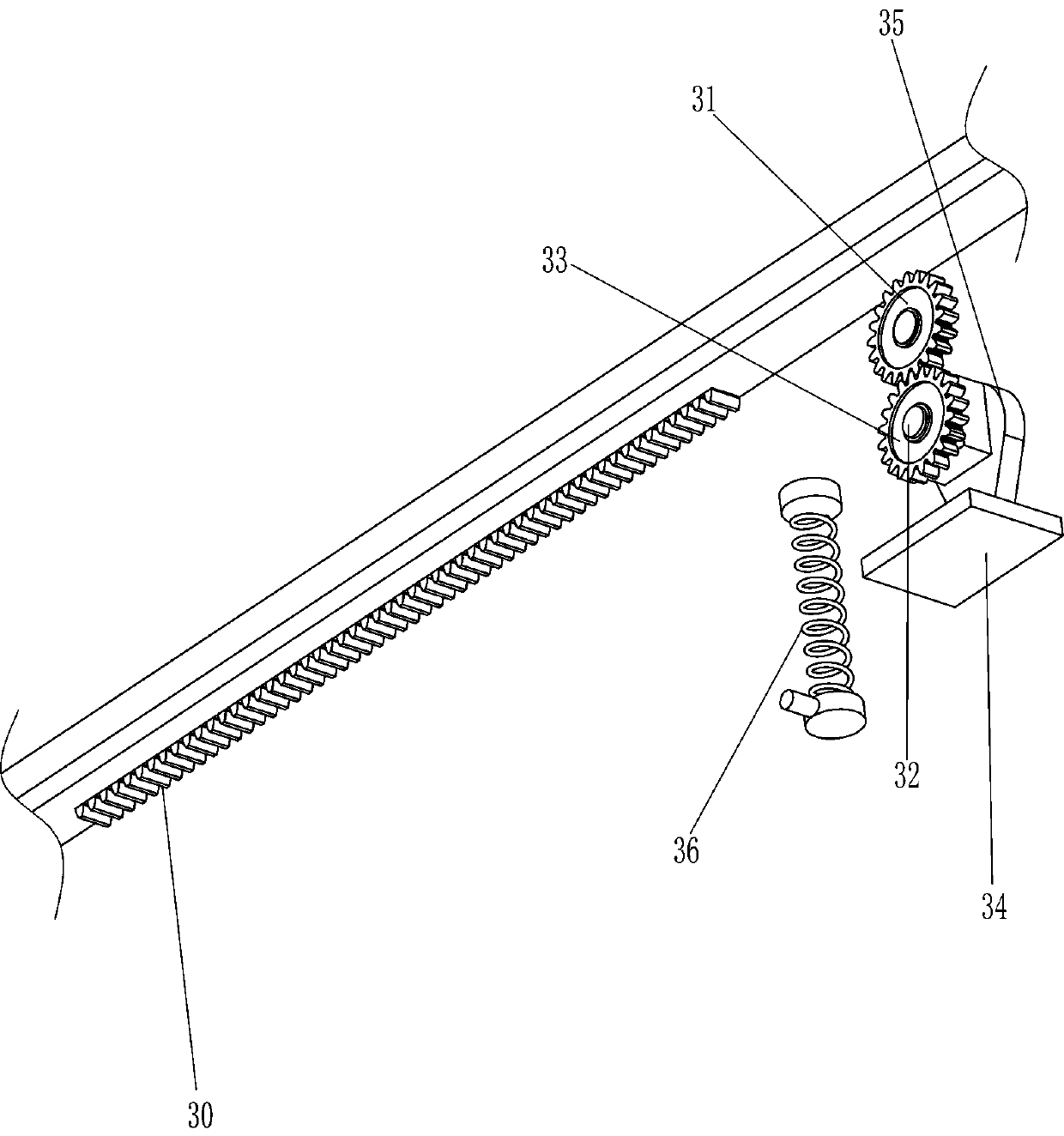

[0031] On the basis of embodiment 1, as attached figure 1 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, it also includes a sliding sleeve 12, a second slider 13, a contact block 14, a third spring 15, a second guide rod 16, a third slider 17, a buffer sleeve 18, a fourth spring 19, a scraper 20, The first rotating shaft 21, the first rotary push block 22, the second rotary push block 23, the torsion spring 24 and the contact rod 25, the middle part of the right side of the placement frame 8 is equipped with a sliding sleeve 12 by a bolt, and the sliding sleeve 12 is provided with a sliding sleeve 12. Two sliders 13, the bottom of the second slider 13 is a slope, the top of the second slider 13 is connected with a contact block 14, a third spring 15 is connected between the contact block 14 and the sliding sleeve 12, and the third spring 15 is wound around the second On the slide block 13, a second guide rod 16 is installed on the front and rear parts of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com