Anti-slope-slipping structure with warning function

An anti-slip and functional technology, applied in the directions of roads, road signs, traffic signals, etc., can solve the problems of lack of initiative and insignificant effect, so as to improve the warning effect, reduce the probability of collision accidents, and reduce the occurrence of traffic accidents. The effect of the probability of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

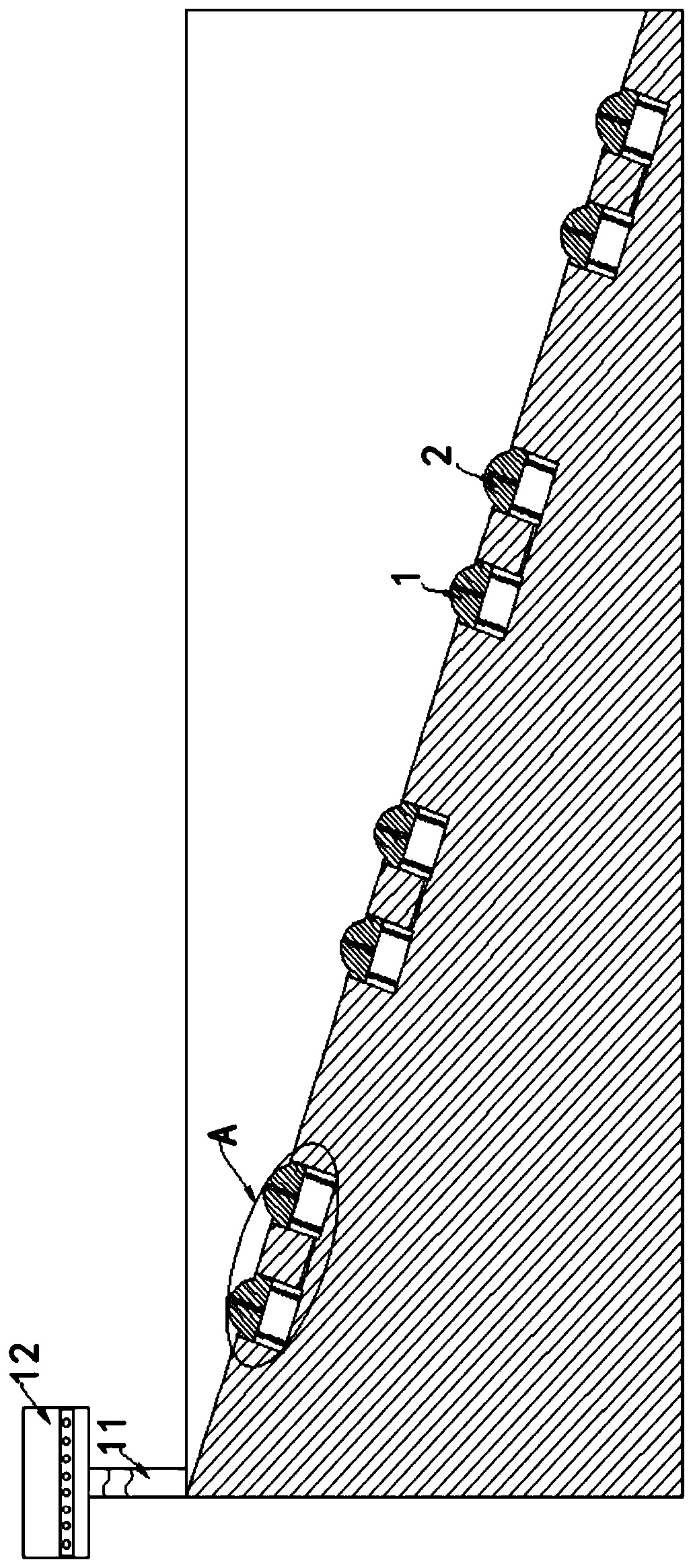

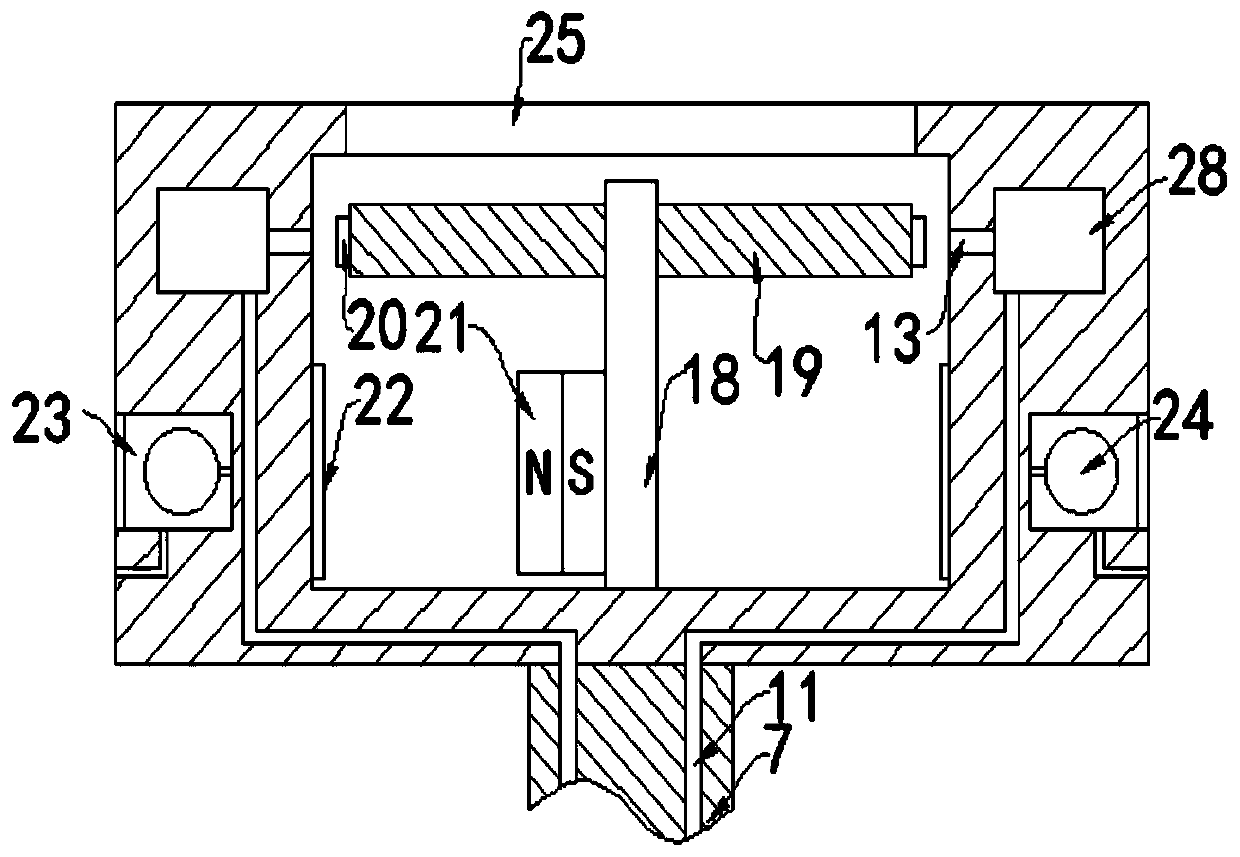

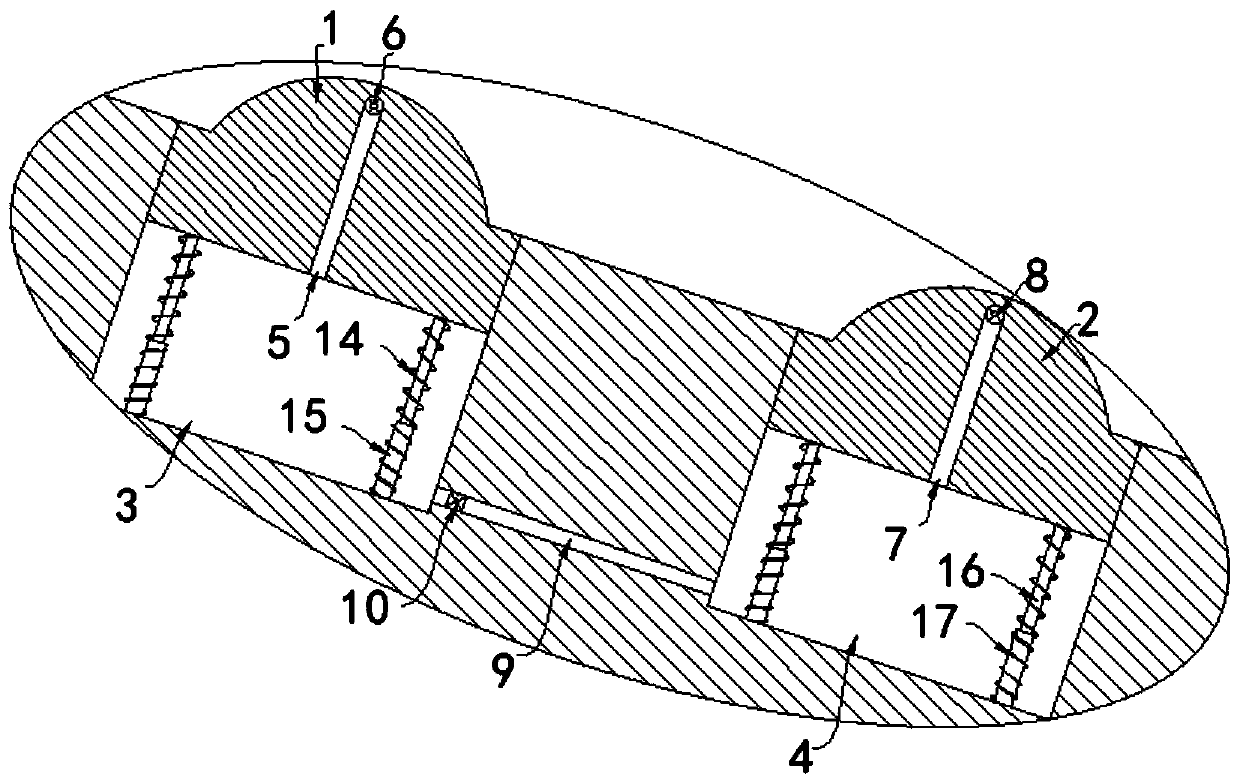

[0022] refer to Figure 1-4 , an anti-slope structure with a warning function, including a first deceleration belt 1, a second deceleration belt 2 and a slope for installing the first deceleration belt 1 and the second deceleration belt 2, and there are multiple first deceleration belts on the slope Groove 3 and a plurality of second grooves 4, the first deceleration belt 1 is slidingly sealed in the first groove 3, and the bottom of the first groove 3 is directly fixedly connected with the first deceleration belt 1 with a plurality of first buffers Assemblies, the side wall of the first deceleration belt 1 is provided with an air inlet 5 communicating with the first groove 3, and a first one-way pressure valve 6 is installed in the air inlet 5, wherein, after the first one-way pressure The air of the valve 6 can only flow into the first groove 3 from the outside, and the second deceleration belt 2 is slidingly sealed in the second groove 4. It should be noted that the first d...

Embodiment 2

[0029] The difference between this embodiment and Embodiment 1 is that a sealing plate 26 is fixedly installed in the opening 25, and an explosion opening 27 is arranged on the sealing plate 26. technology, so I won’t go into details here.

[0030] In this embodiment, when the air entering the warning box 12 is discharged to the outside through the explosion port 27, it can produce a piercing sound, which can further improve the safety warning function of the device at the exit of the garage by cooperating with the flashing lights.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com