Automatic blow-drying equipment and blow-drying method for nuclear power air cooling radiator

A radiator and air-cooling technology, which is applied in the field of automatic drying equipment for nuclear power air-cooled radiators, can solve problems such as the difficulty of quickly and effectively removing moisture from the radiator core, reduce labor costs and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation of the automatic drying equipment and drying method of the nuclear power air-cooled radiator of the present invention will be described in detail below in conjunction with the accompanying drawings.

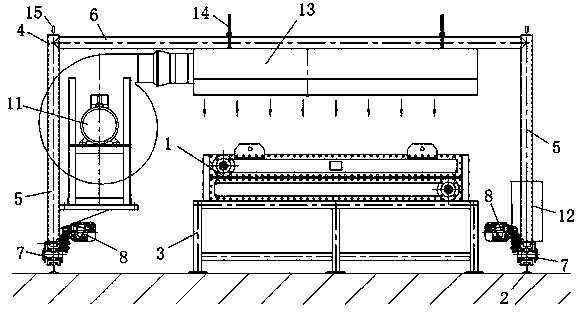

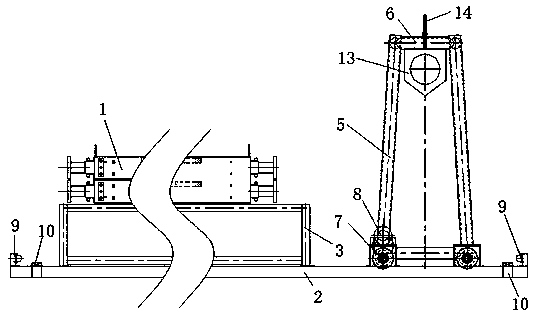

[0039] See attached figure 1 , 2 , The automatic drying equipment for nuclear power air-cooled radiators includes guide rails 2 arranged on both sides of the air-cooled radiator 1 in the length direction, and the guide rails 2 are fixed on the ground or in the workshop. The length of the guide rail 2 is slightly longer than that of the air-cooled radiator 1, and the air-cooled radiator 1 is arranged on the radiator support 3, so that the air-cooled radiator 1 forms an air flow space.

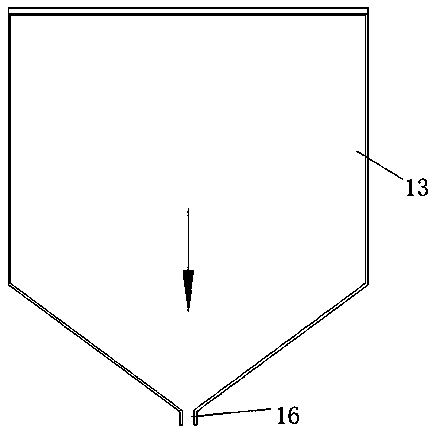

[0040] A gantry-type air duct device frame 4 is provided on the guide rail 2, including two columns 5 and a crossbeam 6 in the middle. The variable-speed driving device 8 is arranged on the two columns 5, and the driving roller 7 rolls to make the air duct devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com