An automated production line for food plastic packaging

An automatic production line and plastic technology, which is applied in the field of plastic processing, can solve the problems of easy shaking of the sheet, slow heating of the sheet, and difficulty in collecting finished products, so as to improve the efficiency of plastic processing, reduce the difficulty, and improve the processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

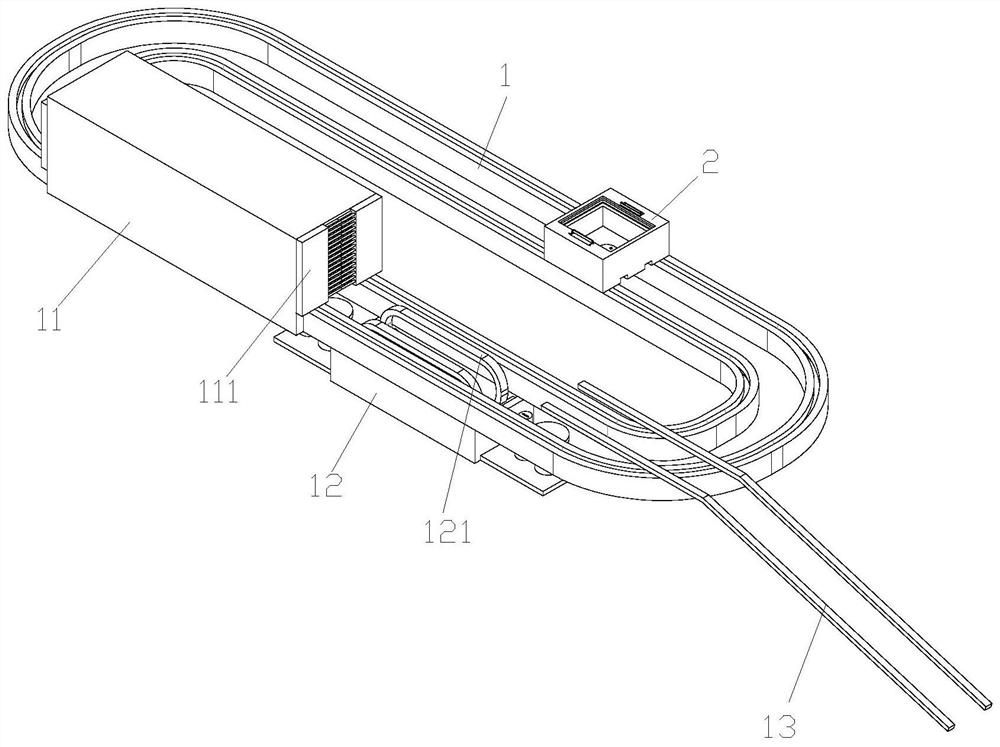

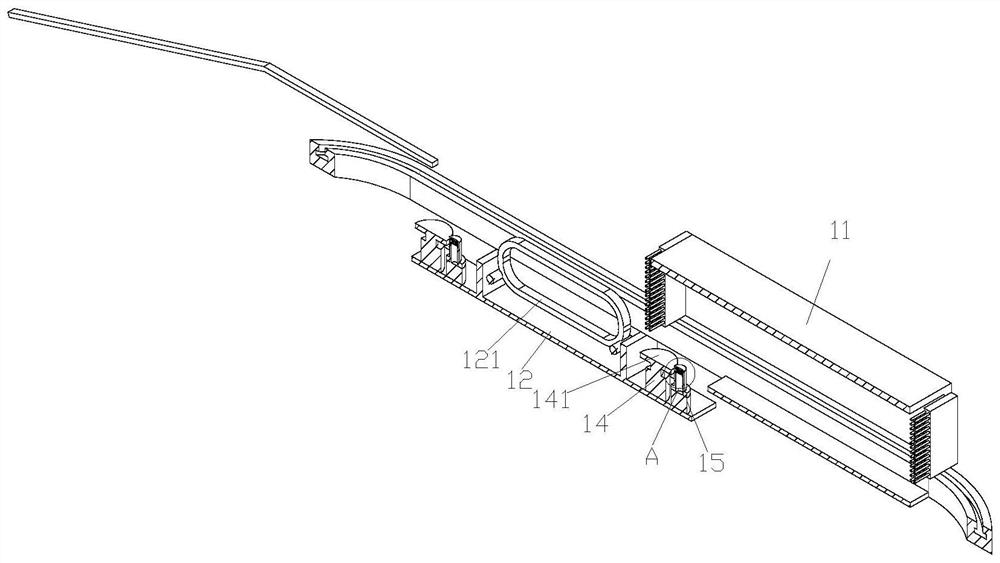

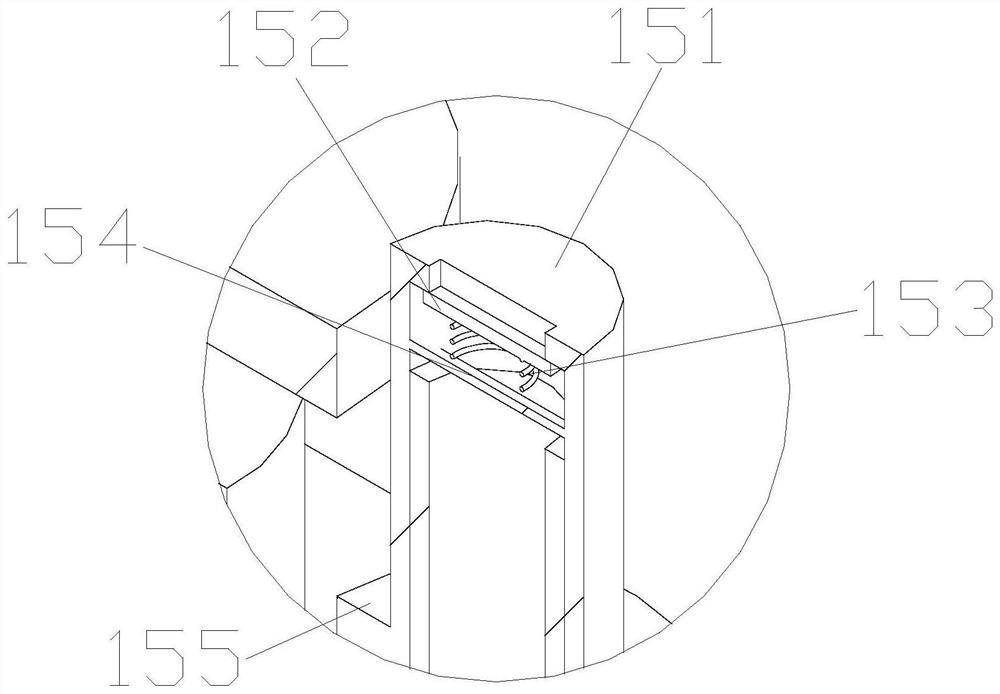

[0026] Such as Figure 1-10 As shown, an automatic production line for food plastic packaging includes a rail 1 and a loading block 2 arranged on the rail 1, a chamber 11 is provided on the rail 1, and a chamber 11 is provided on the inner wall of the chamber 11. Radiation heater, the inner wall of the chamber 11 is provided with a plurality of lenses; the side wall of the chamber is rotatably connected with a cover plate 111, and one end of the cover plate is provided with a plurality of bristles, which increases the thermal insulation effect of the chamber under the action of the cover plate , to avoid excessive dissipation of heat in the chamber, the bristles and the cover plate cooperate with each other, so as to push the cover plate to turn over when the loading block moves, so that the turning of the cover plate is more convenient; The air pump 15 matched with the material block 2, the loading block 2 is provided with a processing tank, the bottom of the processing tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com