Electrostatic chuck function hole anti-blocking device

An electrostatic chuck and functional hole technology, which is used in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems affecting the functionality of pores, electrode holes, and pin holes, and is difficult to clean, and achieves simple structure, energy saving and high efficiency. Cost, Ease of Use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The bonding process is usually used as an integration method in the electrostatic chuck manufacturing process. The bonding process is a method of connecting at least two parts together through an adhesive. Compared with welding, brazing and screwing, it has many advantages, such as firm bonded joints, good fatigue resistance, uniform load distribution, and It satisfies the connection of different materials very well. The bonding process is widely used in the processing and manufacturing process of semiconductors, such as chip packaging, wafer stacking, and the connection of various functional components of electrostatic chucks.

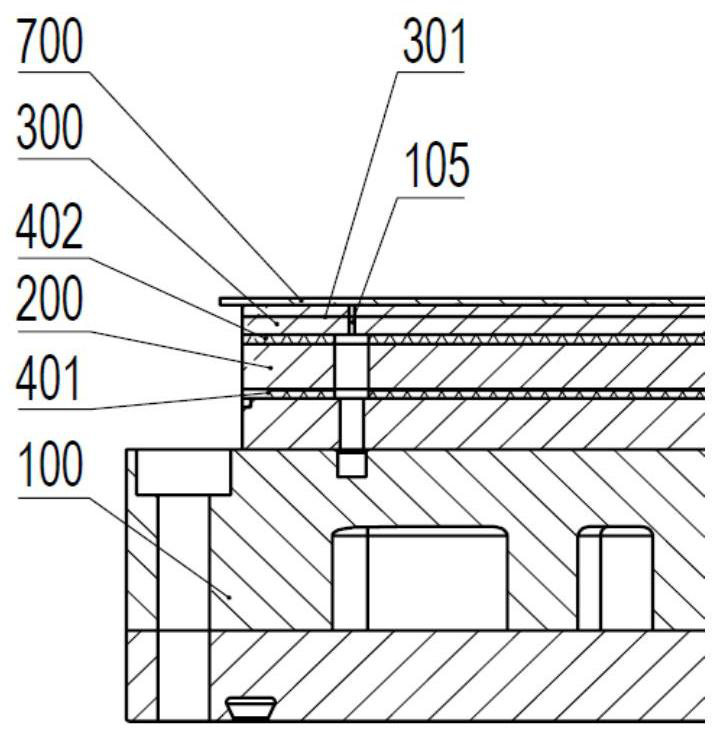

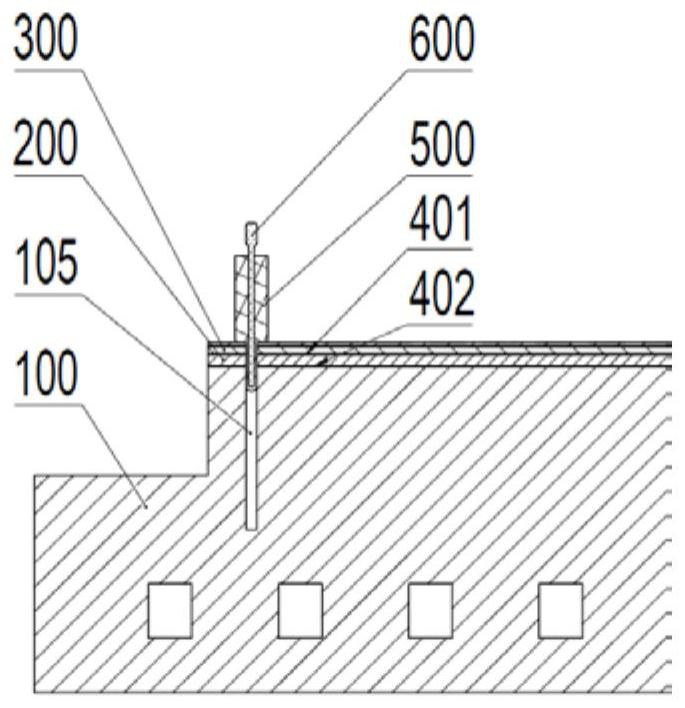

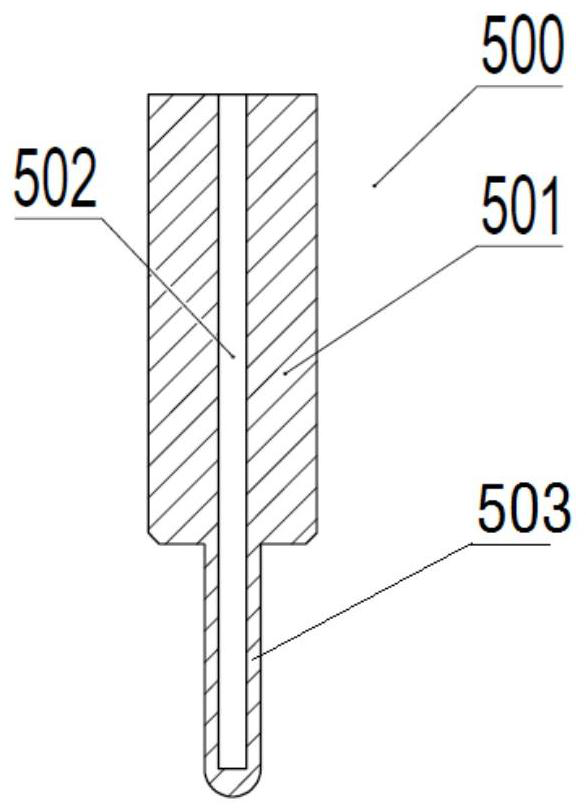

[0026] Such as figure 1 As shown, the composition of the electrostatic chuck is sequentially provided with a metal base 100 , a first adhesive layer 401 , a heater 200 , a second adhesive layer 402 and an insulating layer 300 from bottom to top. Wherein, a vertically penetrating Pin hole (not shown in the figure) is provided inside the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com