Metal liquid directional pouring method for casting and molding

A casting molding and pouring method technology is applied in the control of pouring molten metal from a casting ladle, casting equipment, metal processing equipment, etc., and can solve the problems of low degree of automation, high risk factor, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

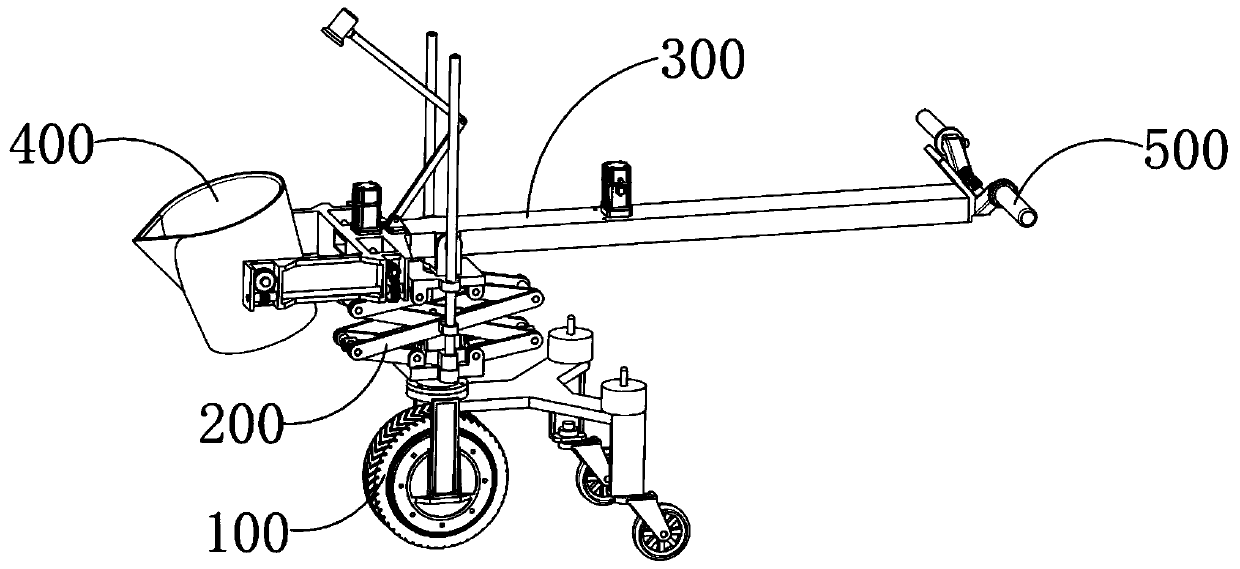

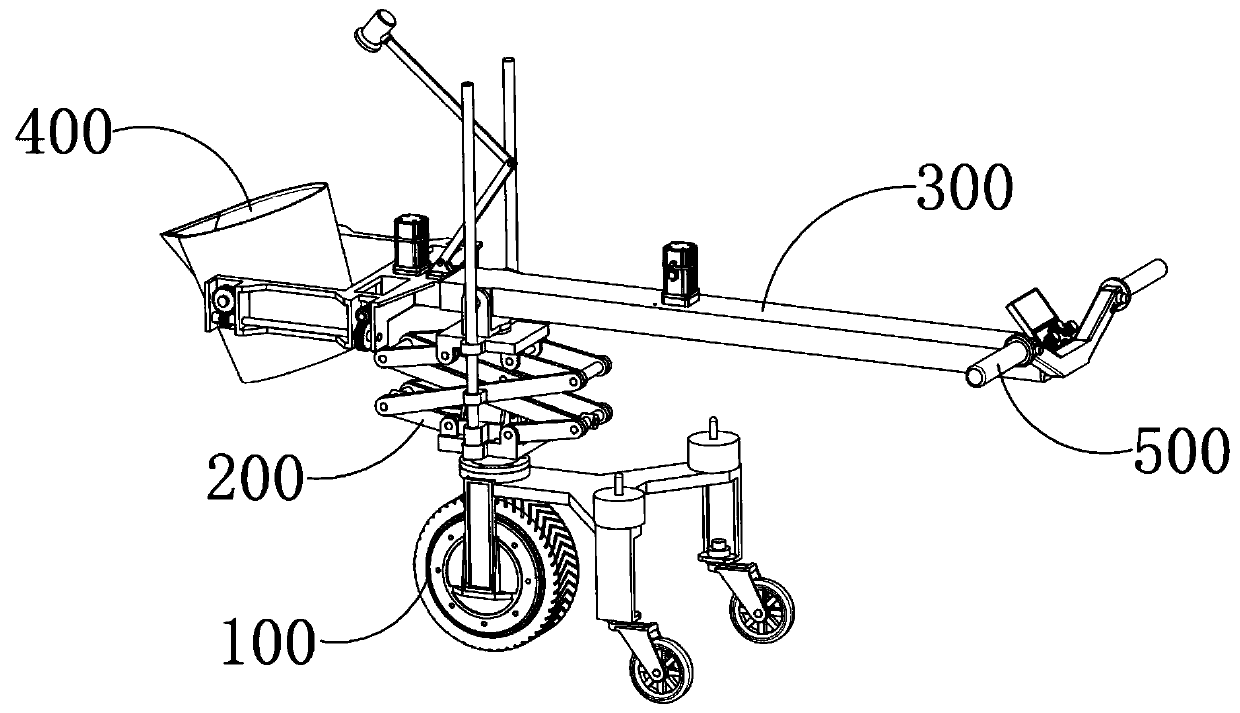

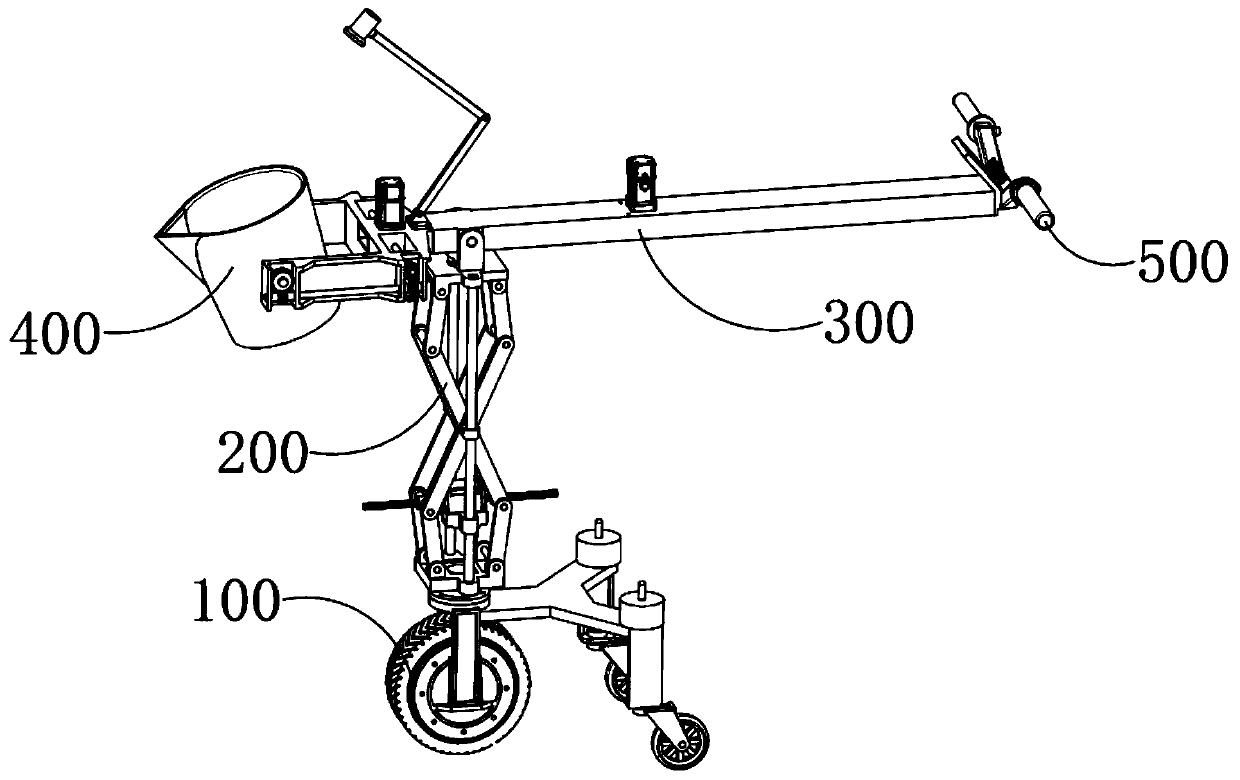

[0069] A metal liquid directional pouring method for casting molding, the steps of which are:

[0070] (1) Telescopic distance adjustment stage;

[0071] S1: first put the molten metal into the container 400, then, the operator holds the control armrest 500 with both hands, starts the telescopic mechanism 300 to gradually extend, and the distance between the telescopic end and the fixed end of the telescopic mechanism 300 increases, The barrel 400 gradually moves away from the operator until the ambient temperature felt by the operator is appropriate;

[0072] The container 400 is set on the telescopic end of the telescopic mechanism 300 and can be tilted, and the control armrest 500 is set on the fixed end of the telescopic mechanism 300 and can control the forward and backward of the traveling mechanism 100, and can control the raising and lowering of the lifting mechanism 100 , can control the elongation and shortening of the telescopic mechanism 300, can control the conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com