Novel intelligent emulsifying device and working method thereof

An emulsification device and intelligent technology, applied in chemical instruments and methods, mixing methods, mixers with rotating stirring devices, etc., can solve problems such as labor-intensive, time-consuming, and manual control troubles, and achieve stable working conditions and improved The effect of cleaning efficiency and improving control efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

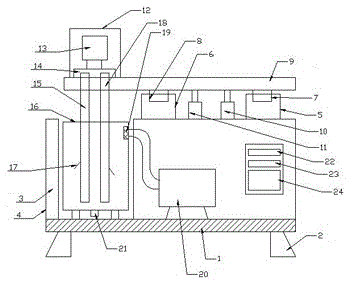

[0016] Such as figure 1 Shown is a novel intelligent emulsification device of the present invention, which consists of a base plate 1, a support leg 2 arranged at the bottom of the base plate 1, and an emulsification pot protection plate 3 and a box frame 4 arranged on both sides of the base plate 1, and the The lifting mixing assembly on the box frame 4, and the material storage assembly that is arranged on the bottom plate 1 and is located between the emulsification pot protection plate 3 and the box frame 4 and used in conjunction with the lifting mixing assembly, and is arranged in the casing of the box frame 4 The control assembly is composed of; the lifting mixing assembly includes the first support card seat 5 and the second support card seat 6 arranged on the box frame 4, and is arranged on the connecting plate 9 and is connected with the first support card seat 5 and the second support card The first positioning card post 7, the second positioning card post 8 used in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com