Steel wire separation fixator for gastrointestinal endoscope maintenance and application method thereof

A technology of separating and fixing steel wires, applied in the field of medical maintenance, can solve problems such as knotting, four steel wires are difficult to keep in position, and waste time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

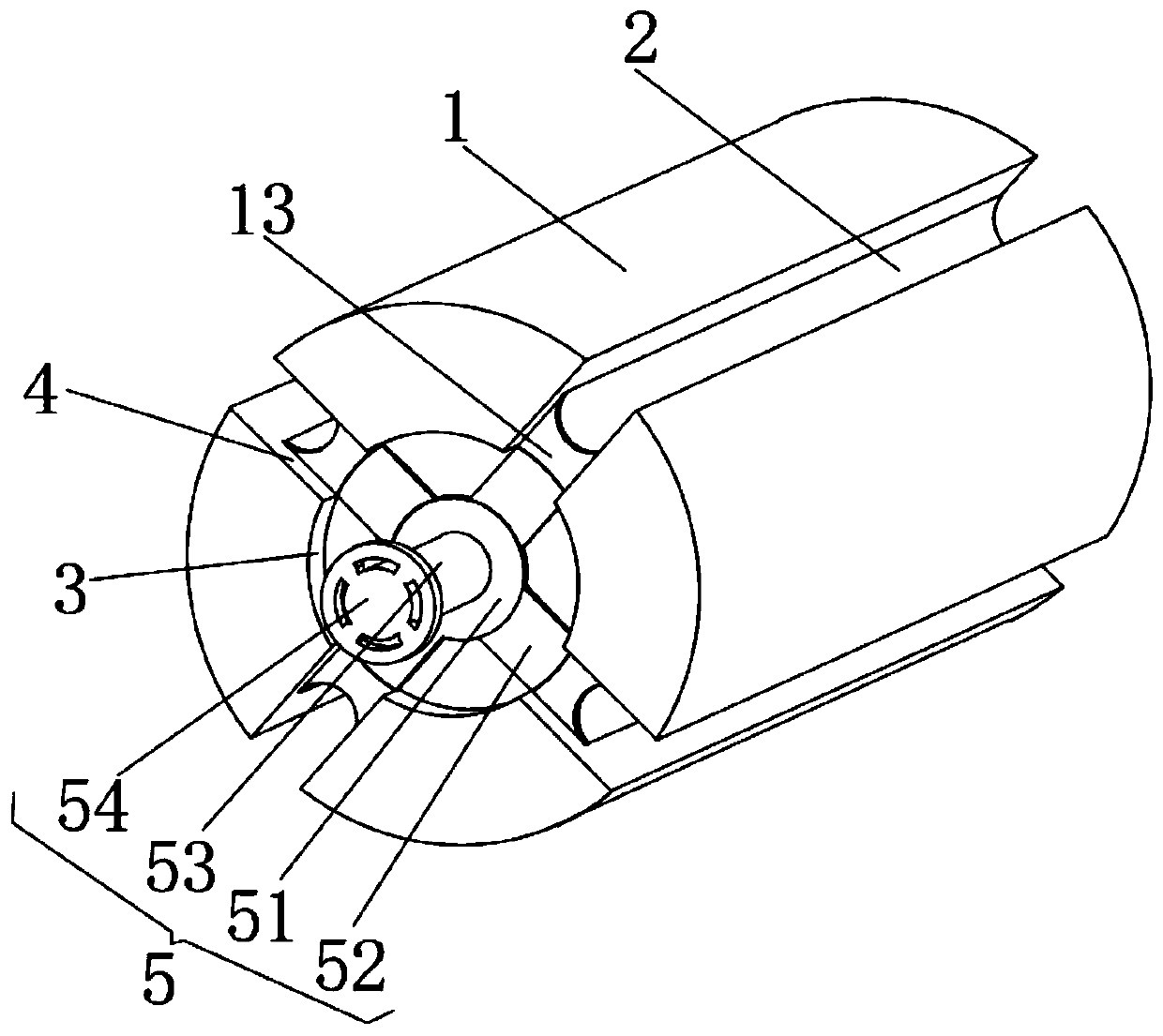

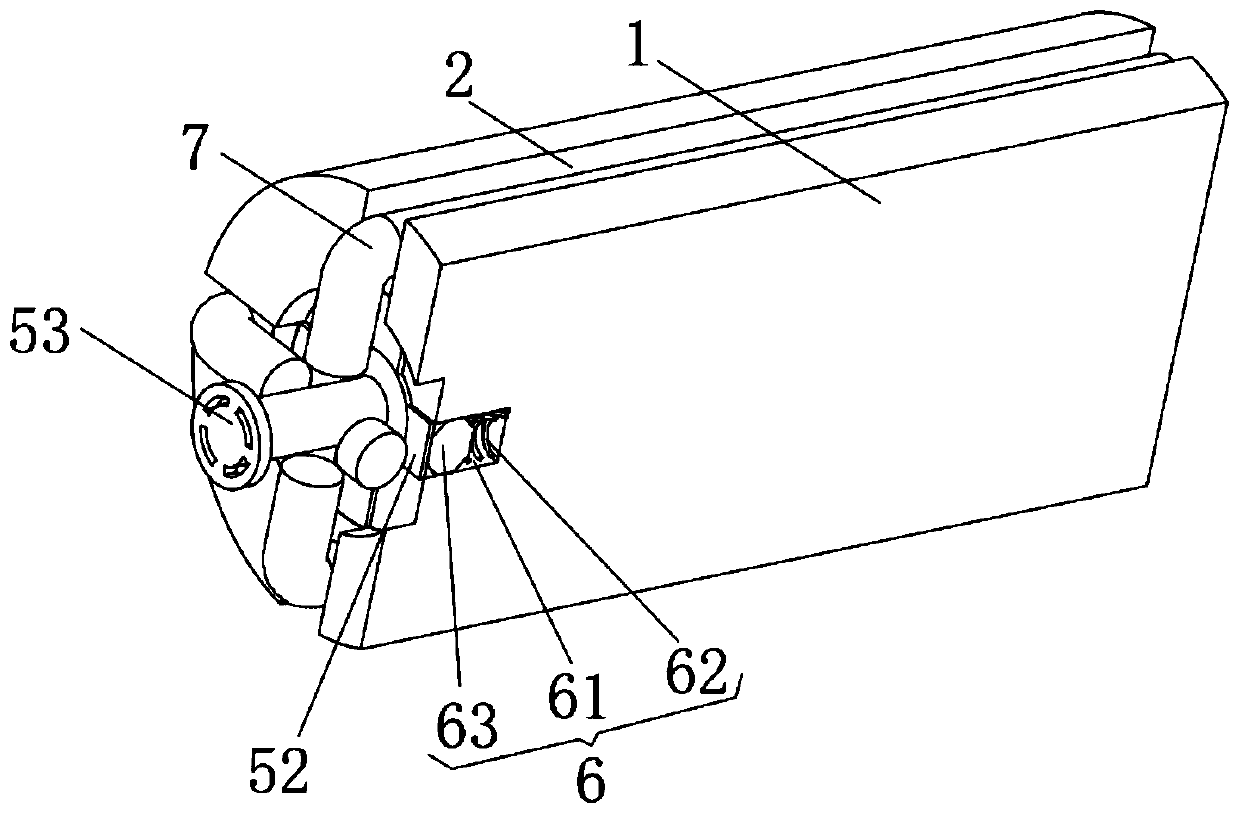

[0024] Embodiment 1: A steel wire separation fixer for gastrointestinal endoscope maintenance, including an inner core 1, a barrier unit 5, a support unit 6 and a limit unit 8, and four corresponding placements are provided on the circumferential surface of the inner core 1 Groove 2, the middle part of the inner core 1 left end surface is provided with a mounting groove 3, and the edge of the inner core 1 left end surface is provided with four corresponding first card slots 4, the first card slots 4 are respectively connected with the placement groove 2 and the installation groove 3 communicate, the barrier unit 5 is installed inside the installation groove 3, the barrier unit 5 includes a turntable 51, a baffle plate 52, a rotating shaft 53 and a handle 54, the turntable 51 is rotatably connected to the inside of the installation groove 3, and the circumference surface of the turntable 51 is fixed with Four mutually corresponding baffles 52, the rotating shaft 53 is fixed on t...

Embodiment 2

[0027] The difference between this embodiment and Embodiment 1 is:

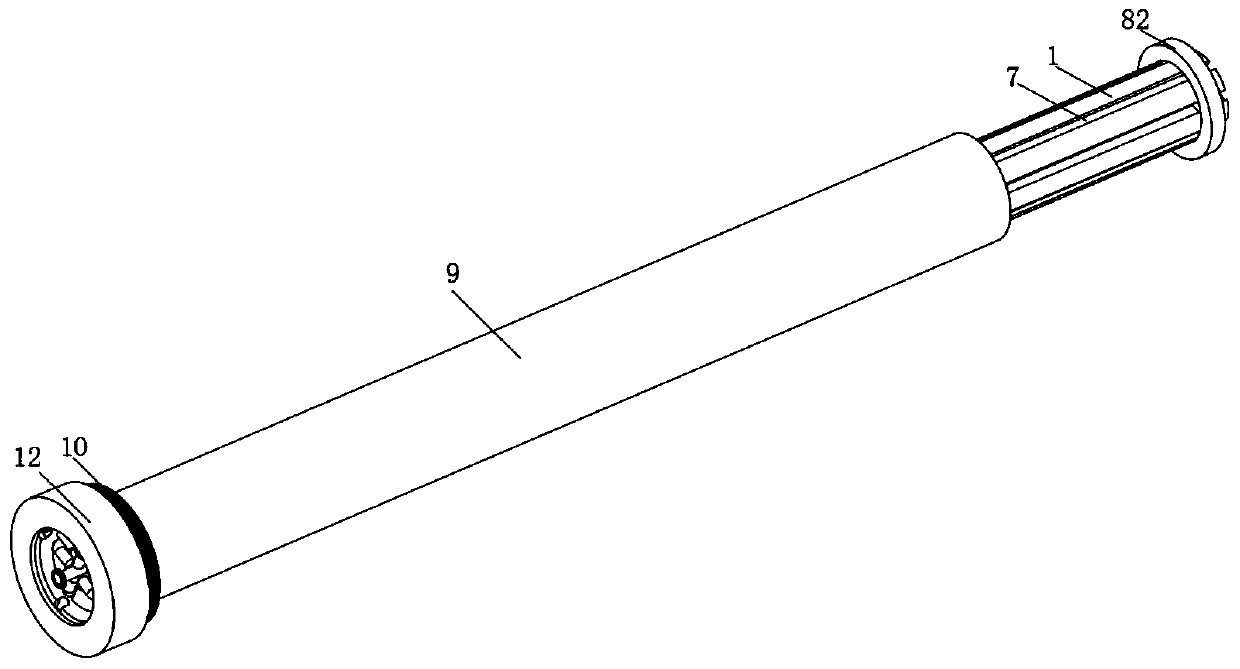

[0028] In this embodiment, it also includes a mirror tube 9 and a gear ring 10, the mirror tube 9 is sleeved on the peripheral surface of the inner core 1, the gear ring 10 is fixed on the peripheral surface of the mirror tube 9, and a second engaging groove 11 is also included. Four corresponding second locking grooves 11 are defined on the left end surface of the gear ring 10 , and the second locking grooves 11 correspond to the first locking grooves 4 .

[0029] Specifically, it is set in such a way that the steel wire 7 is fixed through the second clamping groove 11 .

Embodiment 3

[0031] The difference between this embodiment and Embodiment 1 is:

[0032] In this embodiment, it also includes a limit cap 12, which is screwed to the left end of the gear ring 10, and the middle part of the limit cap 12 is provided with an opening, and also includes a gasket 13, and the gasket 13 is provided with four, four A gasket 13 is correspondingly fixed in the interior of the four first slots 4 .

[0033] Specifically, it is set in this way that the steel wire 7 is fixed inside the second clamping groove 11 through the limit cap 12 , and the steel wire 7 can be clamped inside the first clamping groove 4 more effectively by arranging the gasket 13 .

[0034] A method for using a wire separation fixer for gastroenteroscope maintenance, comprising the following steps:

[0035] S1. Place the four steel wires 7 inside the four placement slots 2, then bend the front ends of the four steel wires 7, and after the steel wires 7 are bent, snap the bent part into the inside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com