Composite single-sided double-thread suture device

A composite material and suture device technology, which is applied in sewing equipment, sewing machine components, sewing machine needle holders, etc., can solve problems such as stress concentration, instability, and resin enrichment, and achieve the effects of reducing motion friction and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with drawings and embodiments.

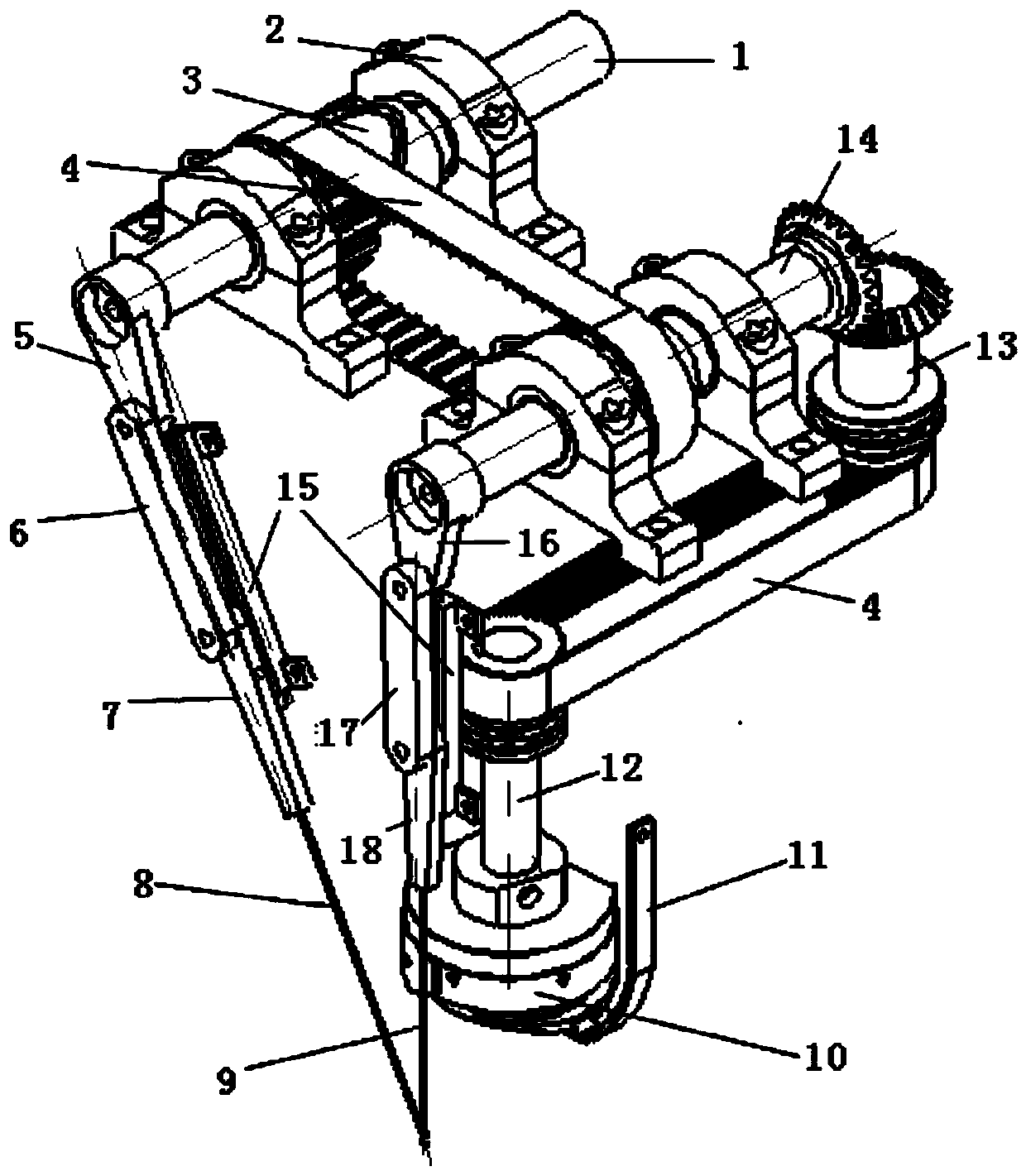

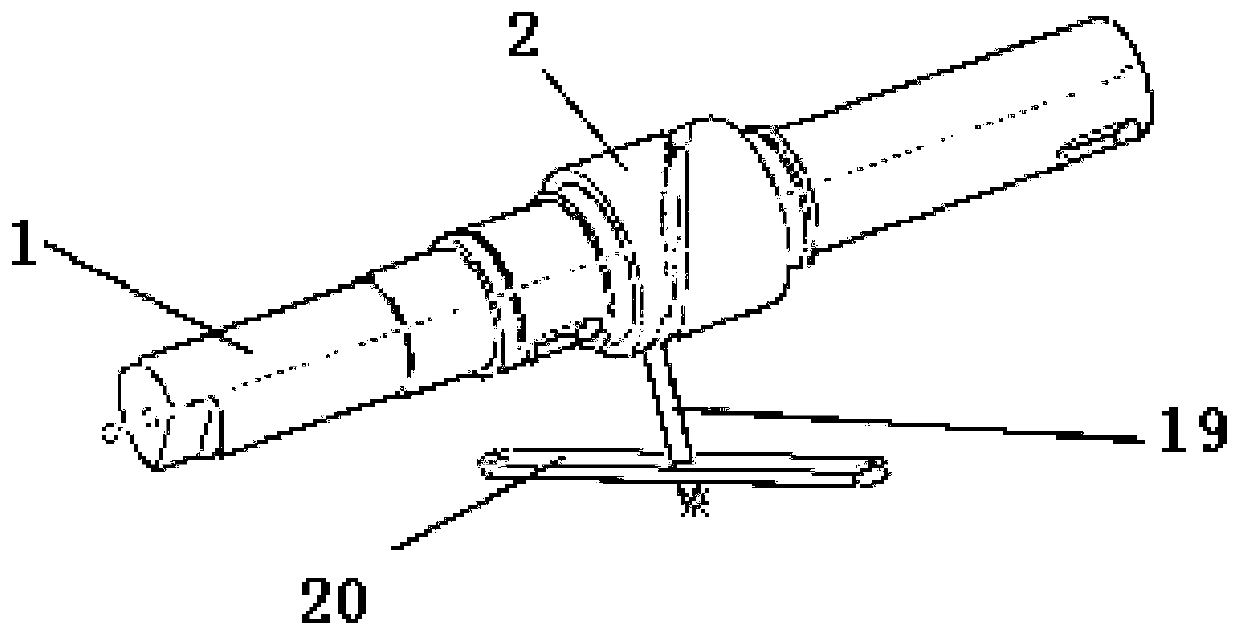

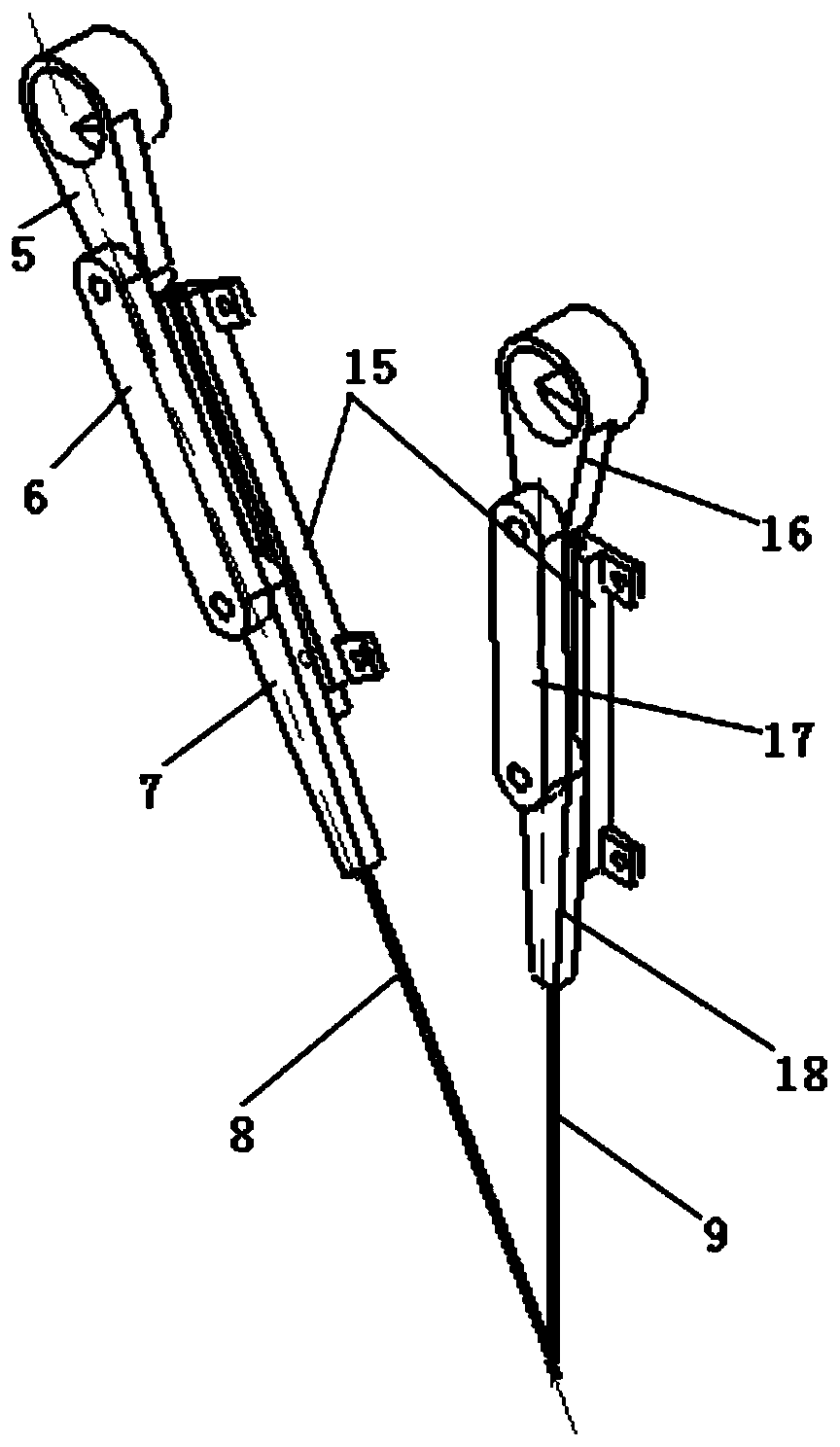

[0036] Such as figure 1 As shown, a single-sided double-thread suture device for composite materials includes a thread pulling lever 20 that can swing back and forth, a rotary hook 10 that can rotate, and a thread-leading needle 8 and a thread take-up needle 9 that can move up and down. There is a thread hole, the shuttle tip of the rotating hook 10 is horizontally downward, the working end of the guide needle 8 is provided with a pinhole and a protrusion is provided above the pinhole, and the protrusion is provided with a groove (such as Figure 4 shown), the working end of the thread take-up needle 9 is an inclined plane and is provided with a hook groove above the inclined plane (such as Figure 5 shown), the upper thread 21 protrudes from the storage place and passes through the thread hole, needle hole and groove in turn, the bottom thread 27 is stored in the bob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com