Installation method for fuel cell air compressor under complex distribution of bolt holes

A technology of fuel cell and installation method, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as general type difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

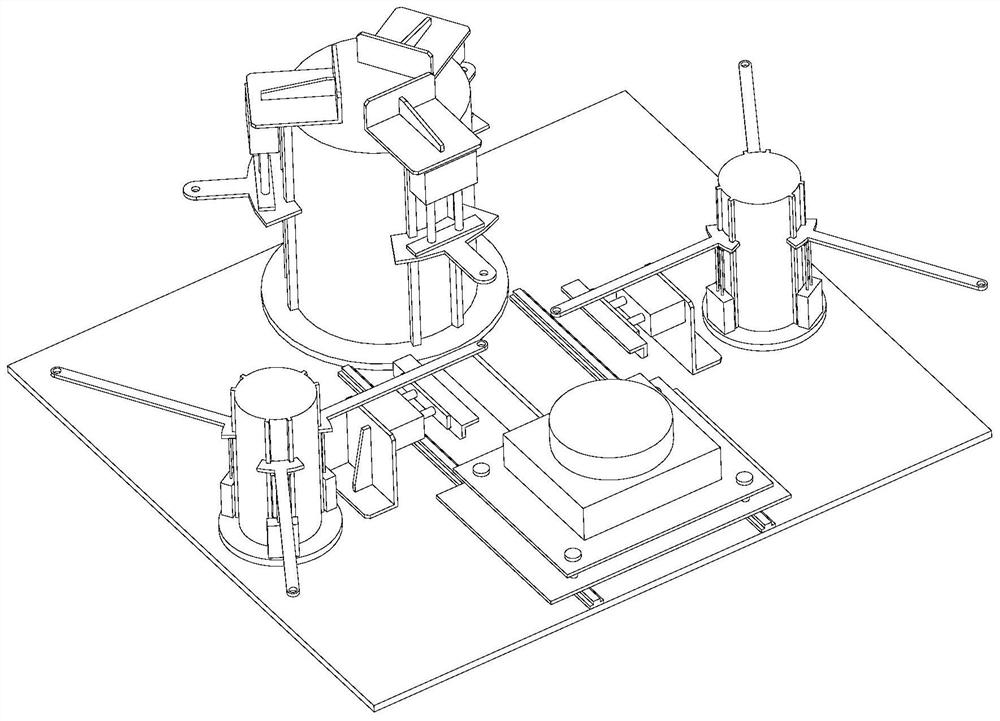

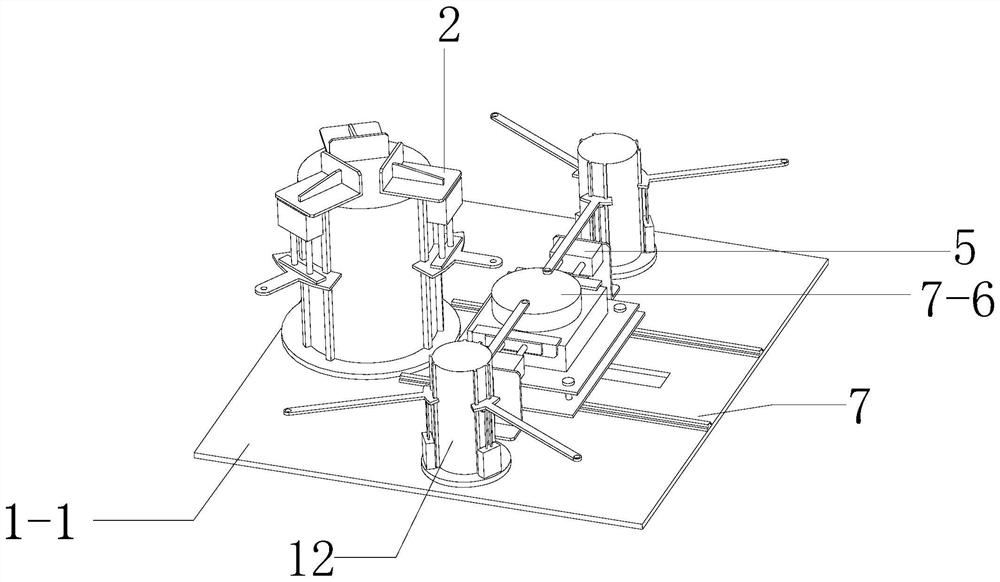

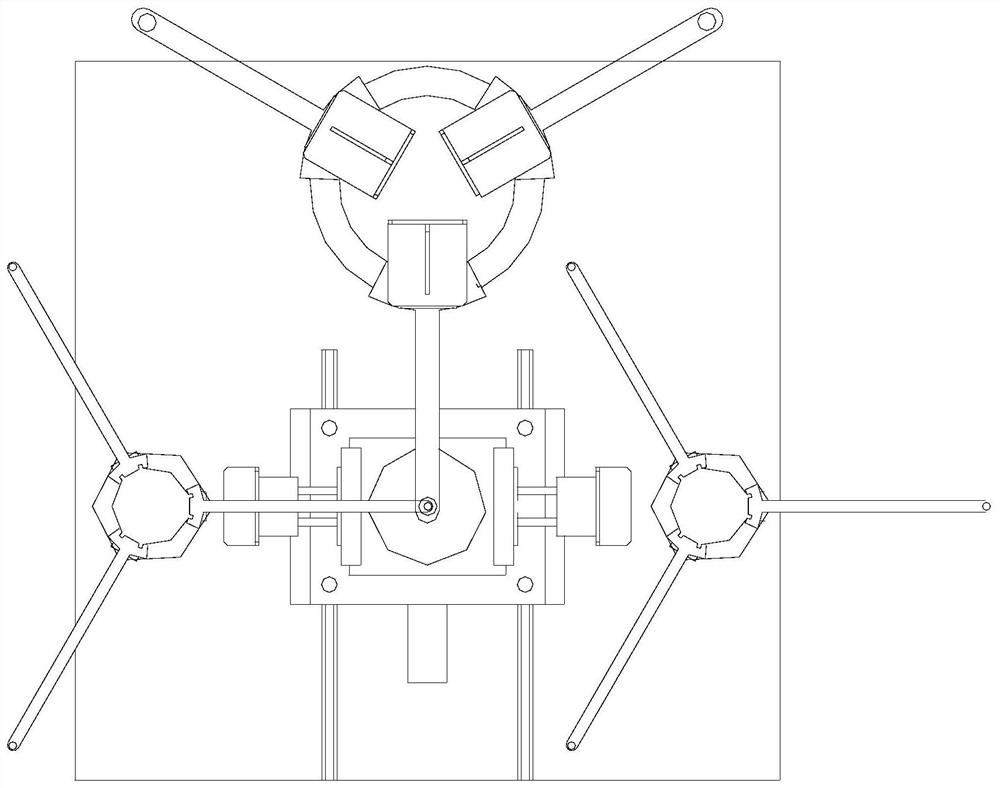

[0170] Embodiment 1, a bolt tightening assembly equipment, including: a frame 1 , a bolt conveying mechanism 2 , a workpiece longitudinal moving mechanism 5 , a workpiece lateral moving mechanism 7 , a tightening mechanism 10 , and two nut conveying mechanisms 12 .

[0171] Wherein, the workpiece lateral movement mechanism 7 includes: workpiece lateral movement telescopic cylinder 7-1, lateral guide rail group 7-2, bearing plate 7-3, connector 7-4, workpiece positioning block placement plate 7-5, workpiece positioning block 7 -6; The horizontal guide rail group 7-2 is fixedly arranged on the platform base plate 1-1, and the telescopic cylinder 7-1 for the lateral movement of the workpiece is placed on the lower side of the platform base plate 1-1. shaped hole, the lower side of the bearing plate 7-3 is fixed with a connecting piece 7-4; the direction of the bar-shaped hole opened by the platform base plate 1-1 is parallel to the direction of the transverse guide rail group 7-2;...

Embodiment 2

[0221] Embodiment two, such as Figure 17 In the case of type A, there are 8 holes (evenly spaced distribution), the internal holes are not provided with threads, and bolt-nut connections are used; type B holes are 6 (evenly spaced), and the internal holes are provided with threaded holes. Threaded hole connections inside workpieces.

[0222] The bolt heads of the bolts to be installed in the A-type hole and the B-type hole have the same size (that is, the bolts in the A-type hole and the B-type hole can be installed by rotation with the same sleeve 10-2).

[0223] face as Figure 17 One problem is: how to determine the installation order of the holes for No. 1 to No. 14 bolts.

[0224] The conventional idea is: No. 1 -> No. 2 -> No. 3 -> No. 4 -> No. 5 -> No. 6 -> No. 7 -> No. 8 -> No. 9 -> No. 10 -> No. 11 -> No. 12 No.->No.13->No.14;

[0225] However, observe Figure 17 The distribution of the bolt holes, obviously, the following scheme is more efficient:

[0226] No....

Embodiment 3

[0259] Embodiment 3: The solution in Embodiment 2 is the optimal solution, but it has a large amount of calculation and is difficult to program.

[0260] A simplified solution is given below:

[0261] Take the projection of the center point of the sleeve 10-2 (hereinafter referred to as: the bolt installation position) on the horizontal plane as the origin during installation (the characteristics of the equipment of this application are: the position of the bolt is unchanged during installation, that is, the sleeve is unchanged, Workpiece movement), the direction of the horizontal guide rail group 7-2 is the X direction, and the telescopic direction of the longitudinal telescopic power mechanism is the Y direction (that is, the direction of the longitudinal guide rail is the Y direction);

[0262] In the initial state, the coordinates of each bolt hole where the workpiece is placed on the workpiece positioning block are:

[0263] No. 1 Bolt Hole: (x 1 ,y 1 )

[0264] ... ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com