Bottom plate built-in rail damper and its design method

A rail shock absorber, built-in technology, applied in the directions of rails, roads, buildings, etc., can solve the problems of weak lateral restraint ability of products, difficulty in lifting lateral restraint, difficult optimization of rubber layer layout, etc., so as to improve lateral restraint performance, The effect of reducing the probability of permanent deformation and improving safe driving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

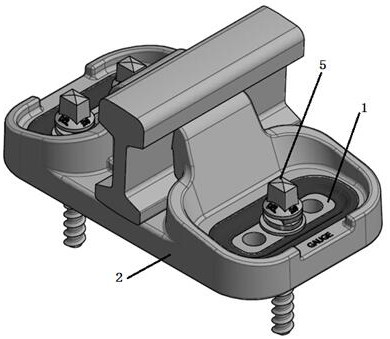

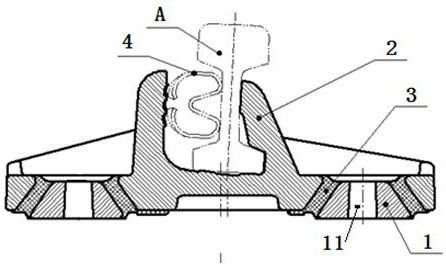

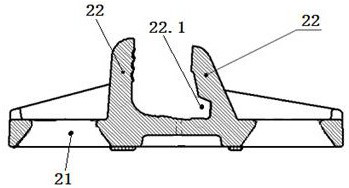

[0031] Combine below Figure 1 to Figure 3 Embodiments of the present invention are described in detail.

[0032] Bottom plate built-in rail shock absorber, including bottom plate 1, top plate 2, rubber layer 3 and elastic buckle clip 4 that cooperates with top plate 2 to press rail A. It is characterized in that the bottom plate 1 is placed in the top plate 2, and the rubber The layer 3 is vulcanized and connected with the top plate 2, and the vulcanized connection surfaces of the bottom plate 1 and the top plate 2 are all inclined surfaces, and the bottom plate 1 is provided with anchoring installation holes 11 for fixing with the sleepers.

[0033] The bottom plate built-in track damper as shown in the figure sets the bottom plate 1 in the top plate 2, that is, the installation position of the track damper is designed inside the product. The size of the bottom plate 1 is smaller, and the vulcanization molding of the top plate 2 is simpler. The requirements for molds, proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com