Patents

Literature

52results about How to "Applicable connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combined high-temperature and durable creeping clamp

ActiveCN101718653AAvoid replacementOvercoming High Temperature Bonding ProblemsStrength propertiesBiomedical engineeringHigh heat

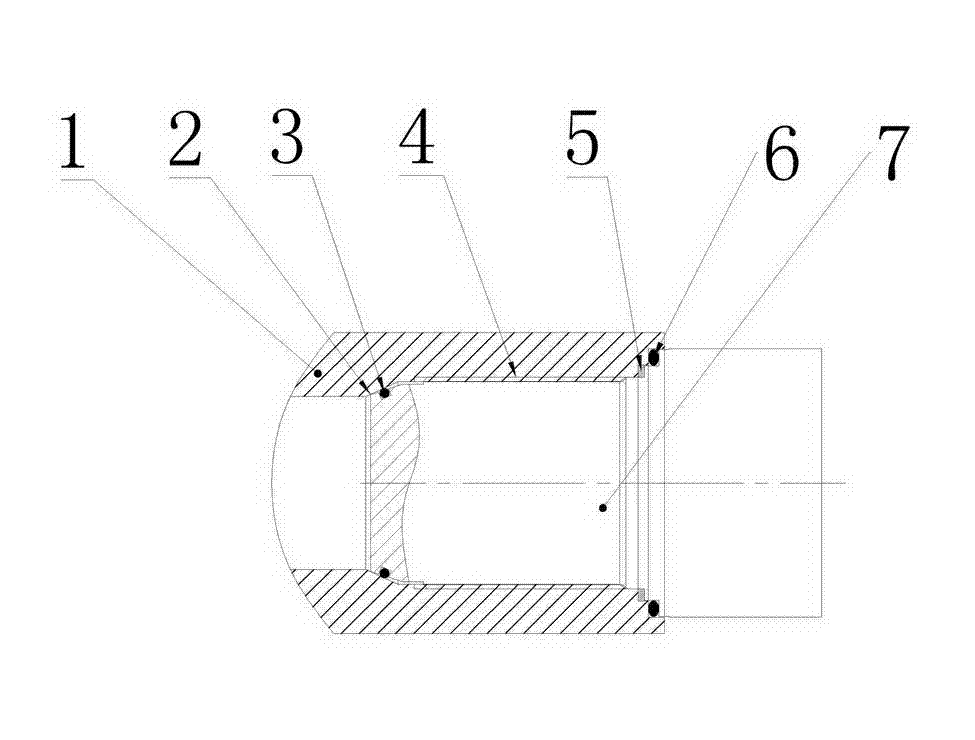

The invention belongs to a mechanics performance testing technology, relating to a combined high-temperature and durable creeping clamp. The clamp comprises a clamp body and two force transferring members, wherein the clamp body is a cavity, openings with the size corresponding to that of the force transferring members are arranged on the clamp body, and the bottom of the clamp body is provided with a through hole adapting to the end of a sample; the two force transferring members are arranged at the bottom of the clamp cavity, the inner surface of each force transferring member is divided into two parts, one part is a pressed part corresponding to the pressed part of the surface of the sample, and the other part is a part corresponding to the pulled part of the surface of the sample, and the two parts of the inner surfaces of the force transferring members are matched with the ends of the sample. The loaded face of the sample can load even loads according to the combined high-temperature and durable creeping clamp so that the problem of test data invalidity caused by uneven stressing in the testing process can be avoided.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

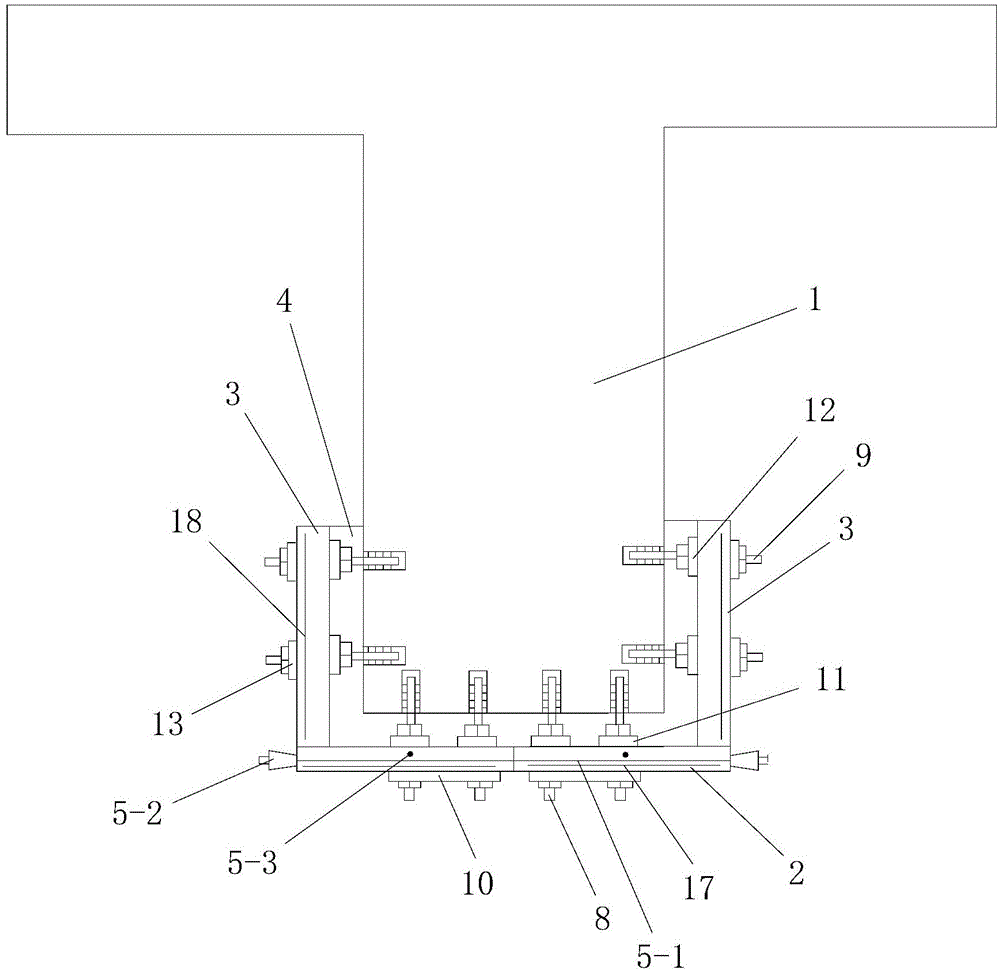

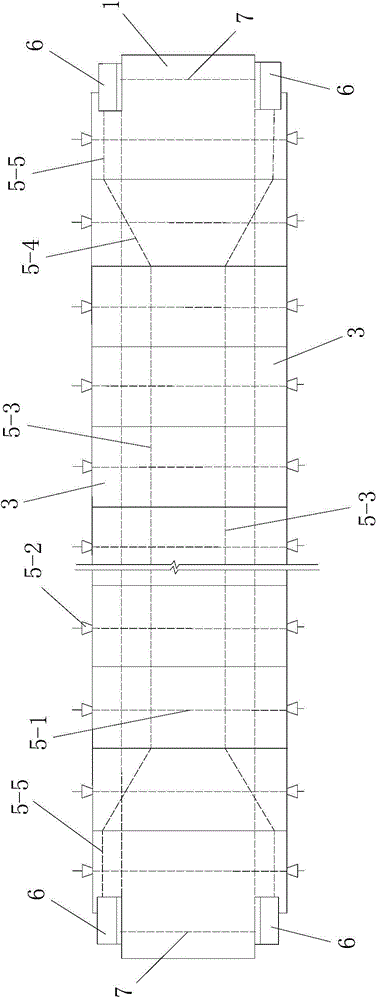

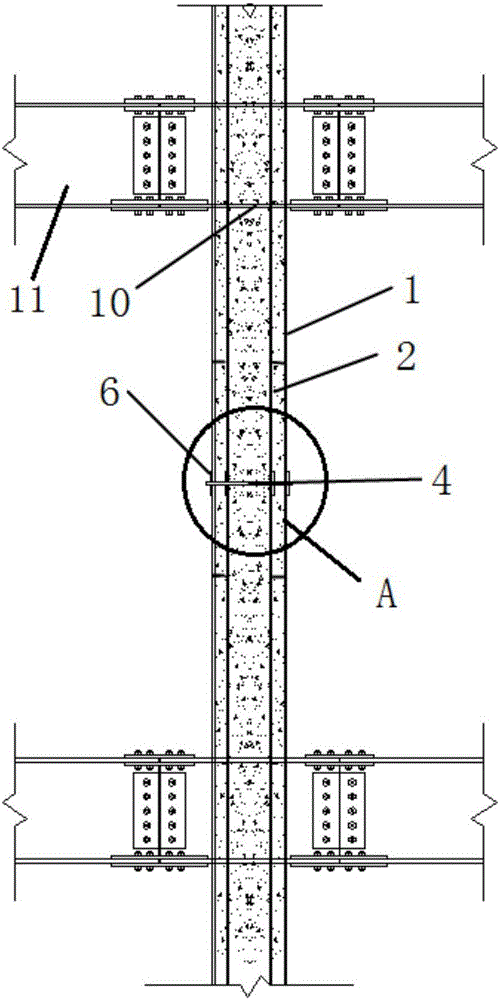

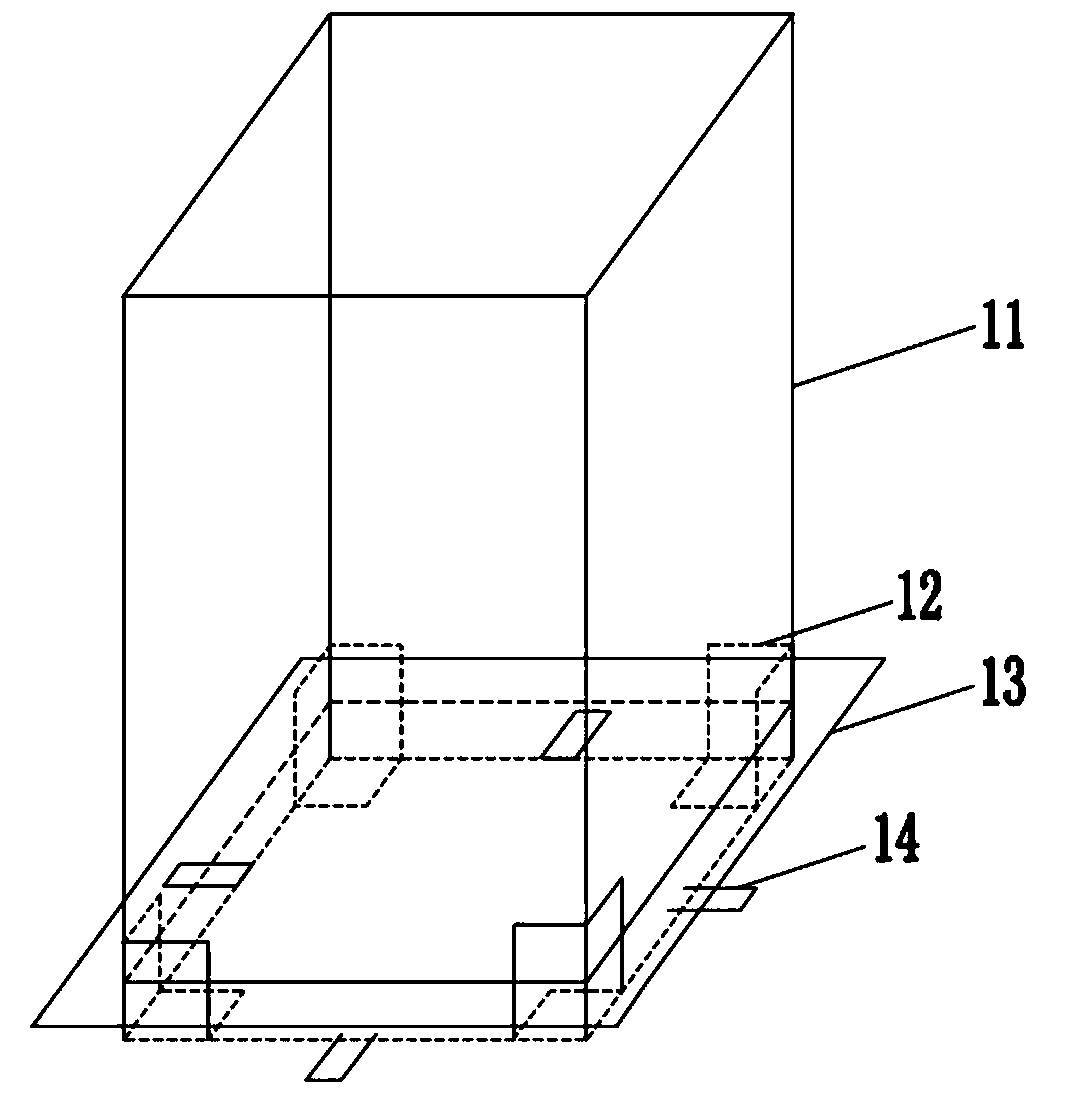

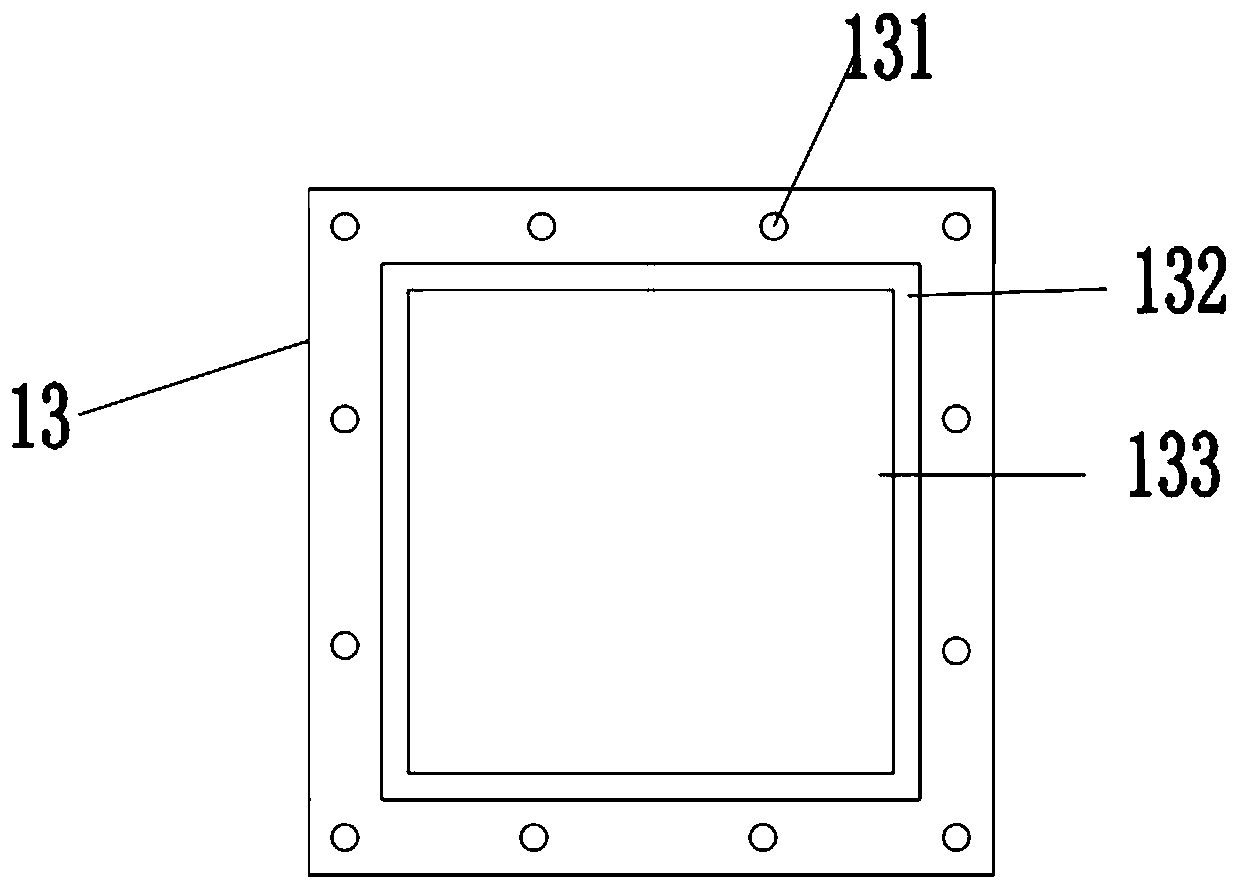

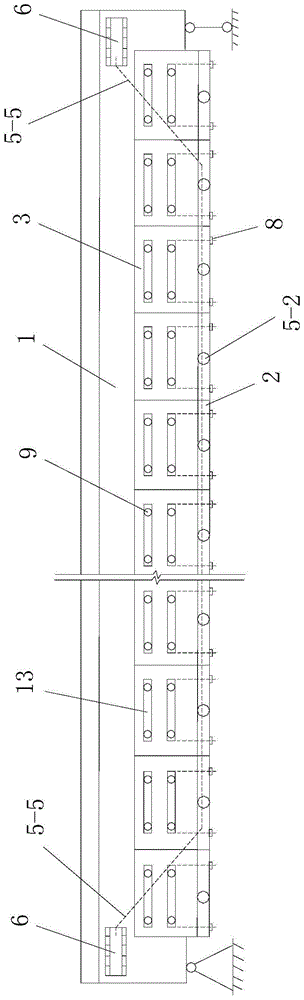

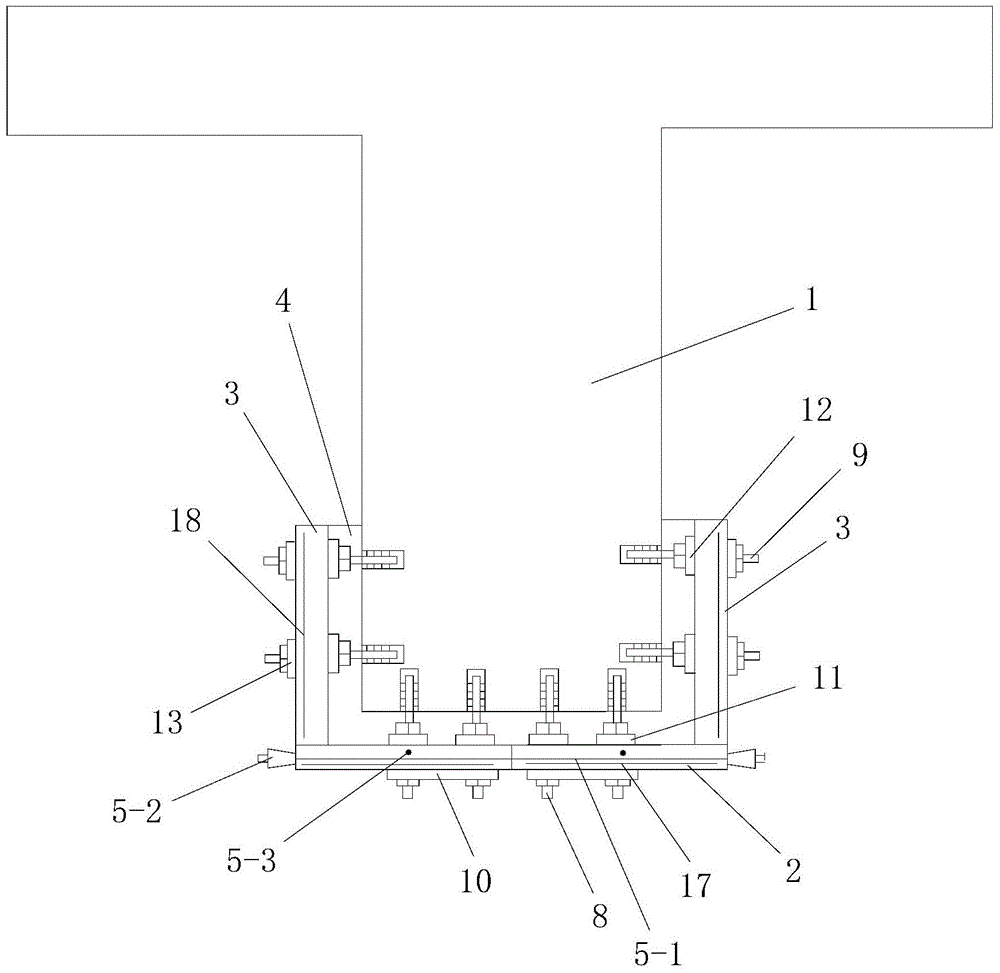

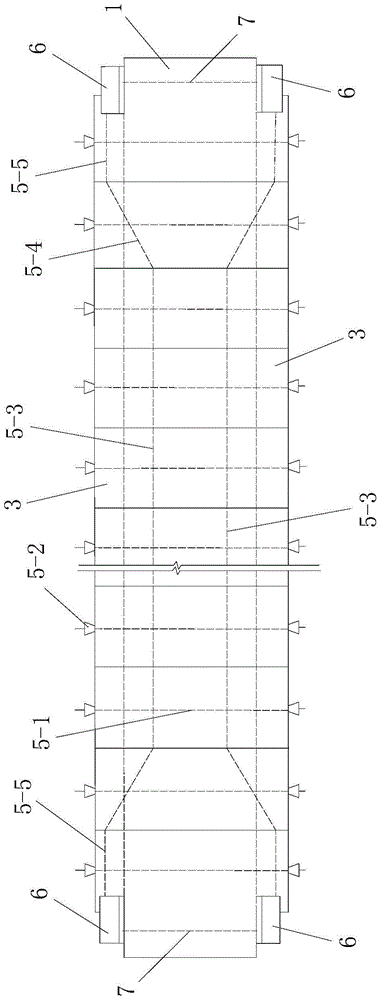

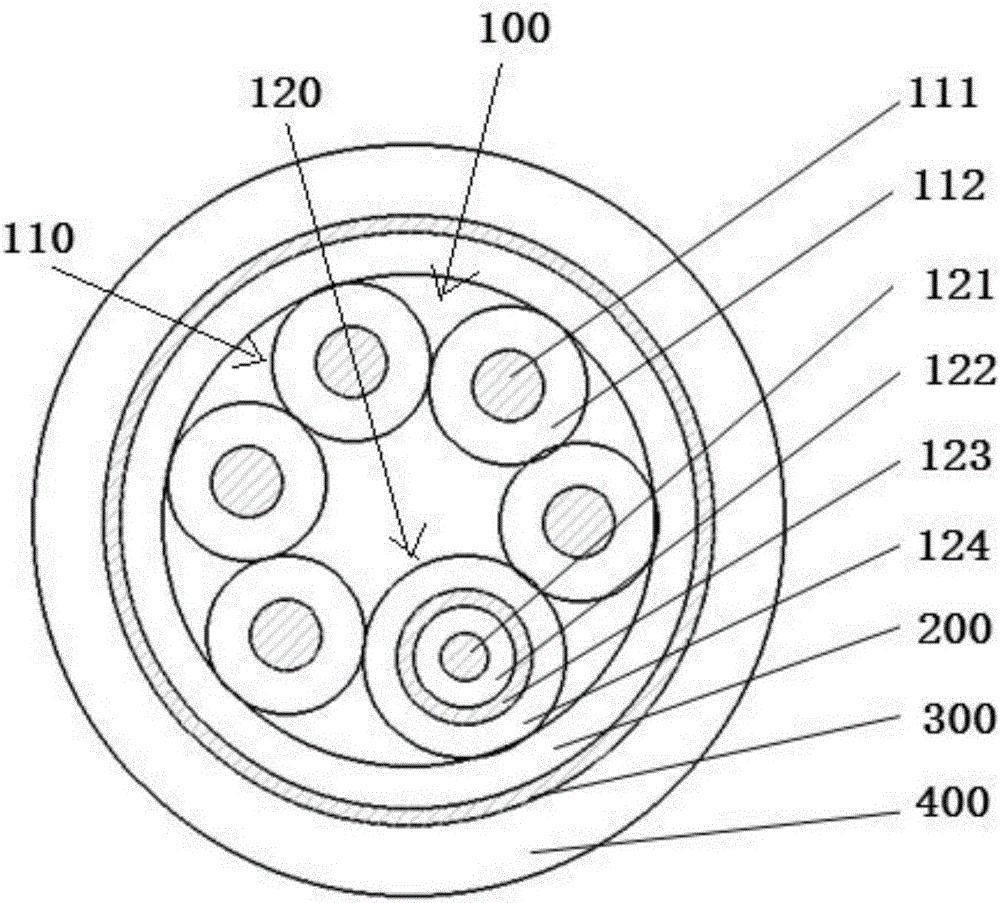

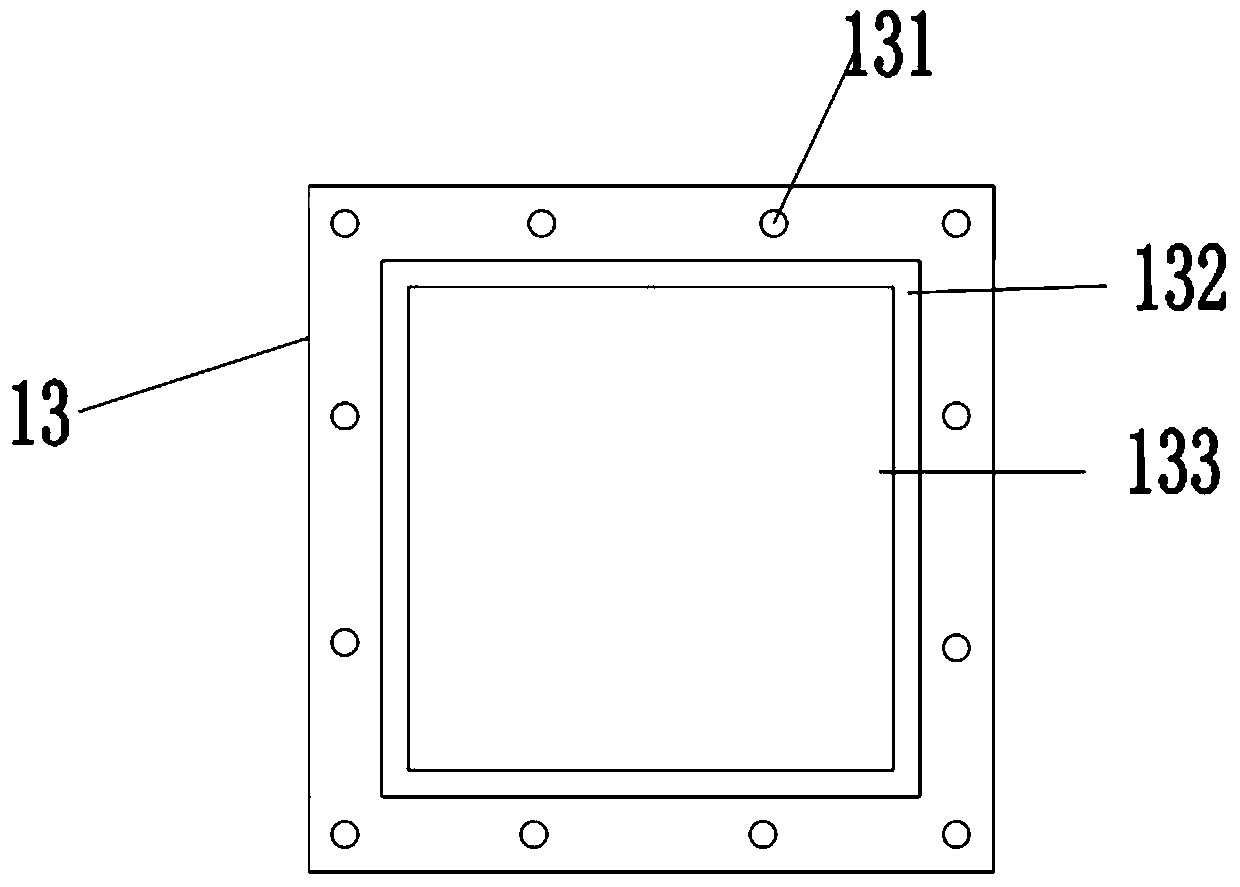

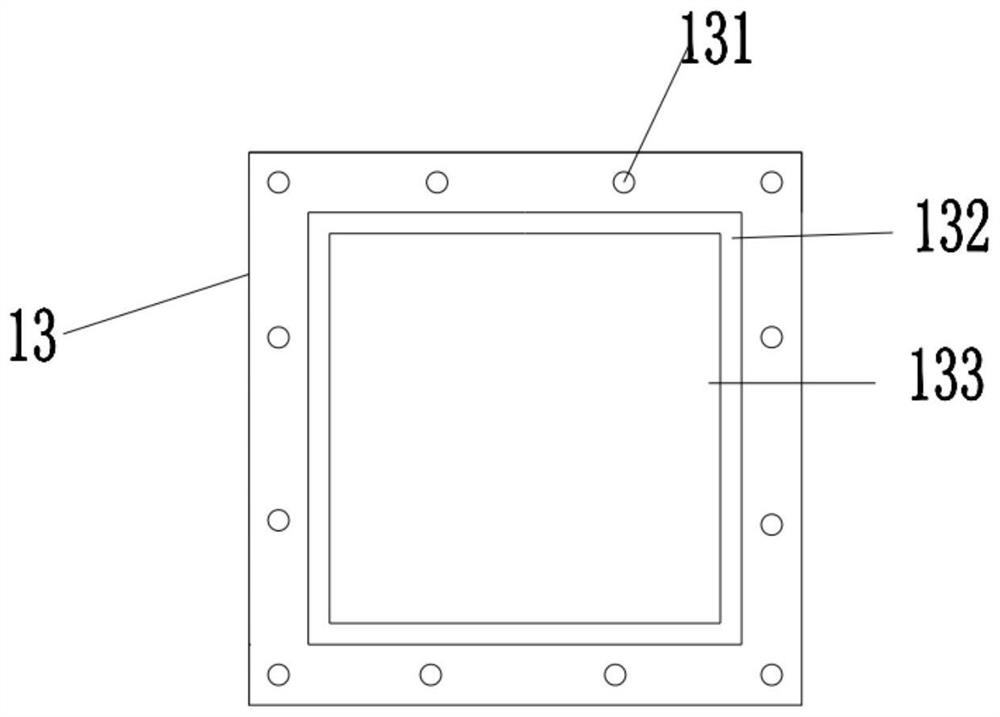

Reinforced concrete girder bridge girder reinforcing structure and method

ActiveCN104947603ASimple structureReasonable designBridge erection/assemblyBridge strengtheningReinforced concretePre stress

The invention discloses a reinforced concrete girder bridge girder reinforcing structure and method. The reinforcing structure comprises a reinforcing form board, a concrete structure located in a cavity between the reinforcing form board and a to-be-reinforced girder and a prestress system arranged on the reinforcing form board, wherein the reinforcing form board includes a girder-bottom form board and two girder-side form boards; the prestress system comprises two longitudinal prestress steel strands penetrating the reinforcing form board and a plurality of first transverse prestress steel strands penetrating the girder-bottom form board, four steel anchor boxes are disposed on the to-be-reinforced girder, and the two longitudinal prestress steel strands, two second transverse prestress steel strands and the four steel anchor boxes form the annular prestress system. The reinforcing method includes the steps of firstly, prefabricating the reinforcing form board; secondly, arranging anchor parts; thirdly, hoisting and fixing the reinforcing form board; fourthly, pouring concrete; performing prestress tension. The reinforcing structure and method is reasonable in design, simple in construction, good in reinforcing effect and capable of solve various problems of existing reinforcing methods.

Owner:XIAN UNIV OF SCI & TECH

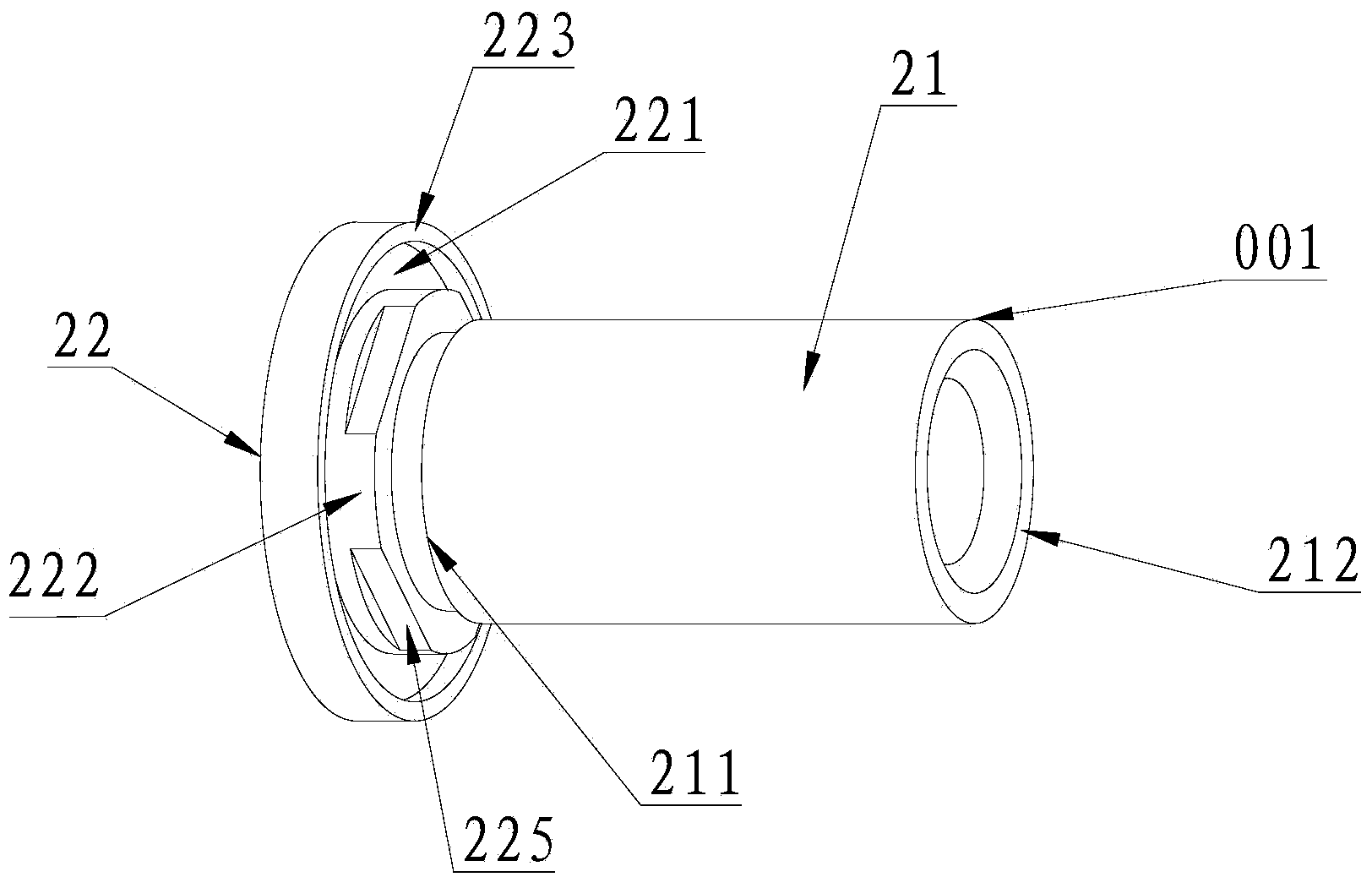

Fixing part used for fixing water heater pipeline

ActiveCN103470885AReduce the chance of water leaksImprove stress resistanceSleeve/socket jointsFluid heatersEngineeringMechanical engineering

The invention provides a fixing part, comprising a body and a boss, wherein the body is of a hollow structure and comprises a front end and a tail end; the boss is arranged on the outer wall of the front end and comprises an L-shaped side face formed by a first side face and a second side face; a bulge facing to the tail end is arranged on the top end of the first side face; the bulge, the first side face and the second side face form a first groove; the height of the bulge is one fifth to three fifths of the width of the second side face; a matching face is milled in the second side face. After the technical scheme is applied, since the design of the first groove is adopted, and a seal ring is used for sealing the first groove, the anti-pressure capability is strong, and the seal performance is good; no professional and technical personnel are needed, so that the cost is low; the matching face is milled in the periphery of the second side face, the fixing part is tightly matched with other devices in the using process, the rotation is prevented, and the seal performance is good.

Owner:HUNAN EWAVV NEW ENERGY TECH

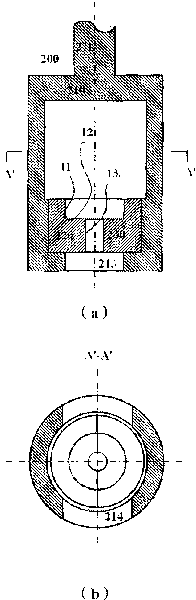

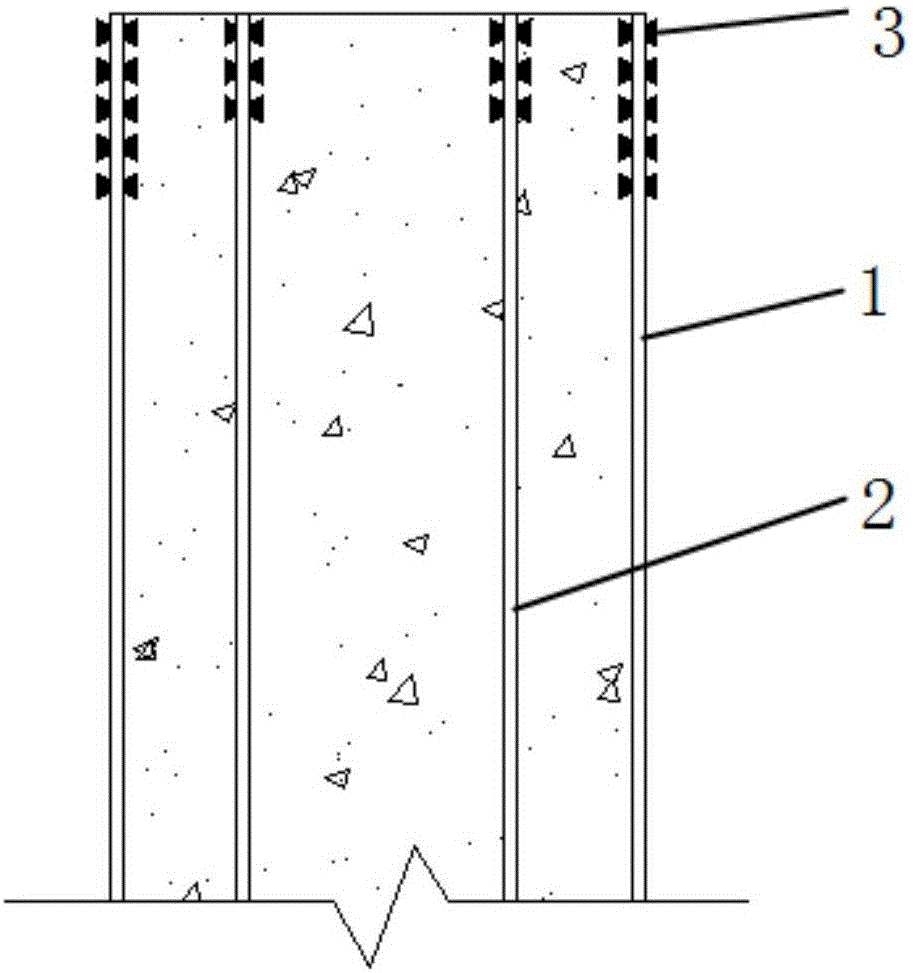

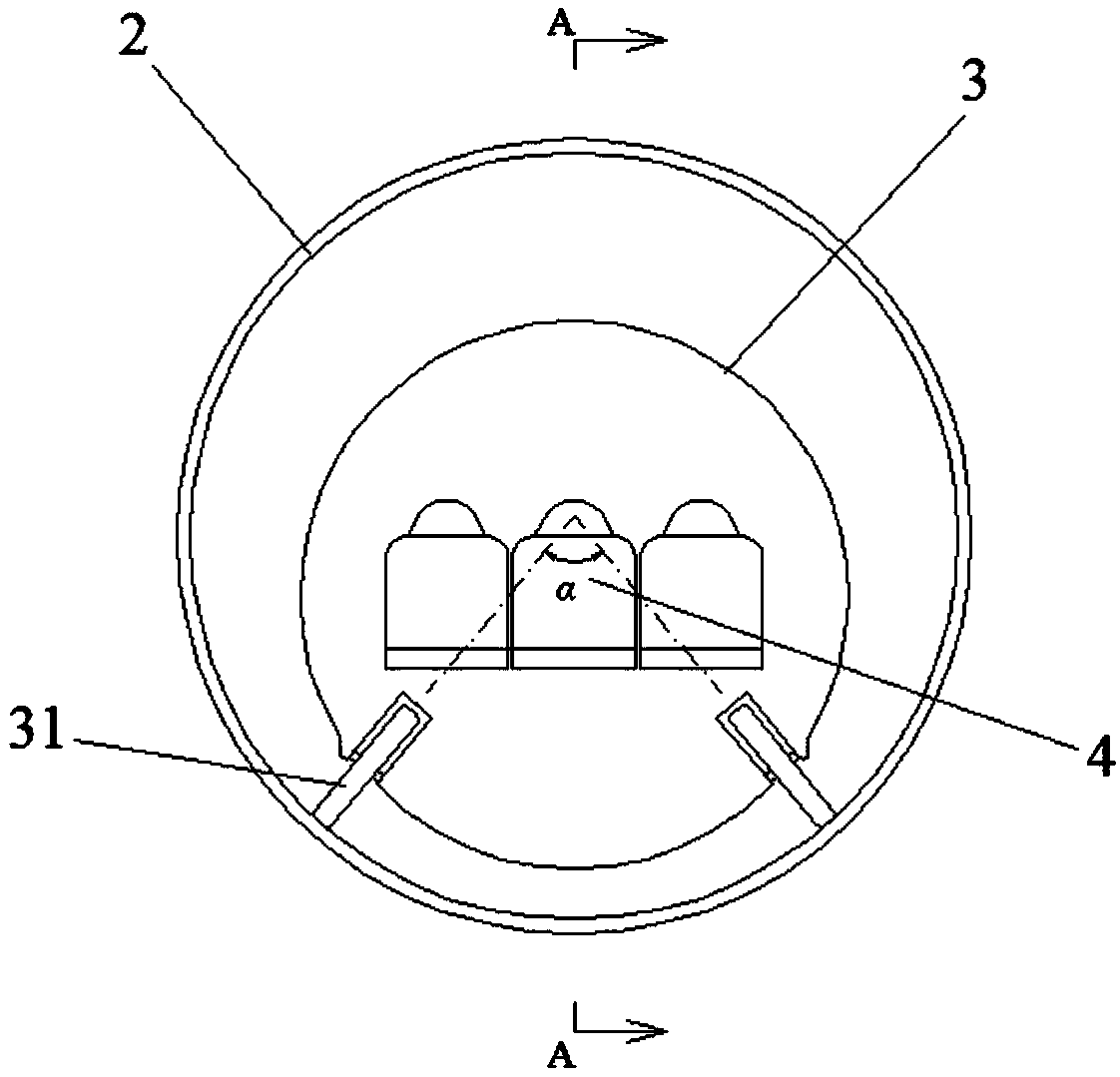

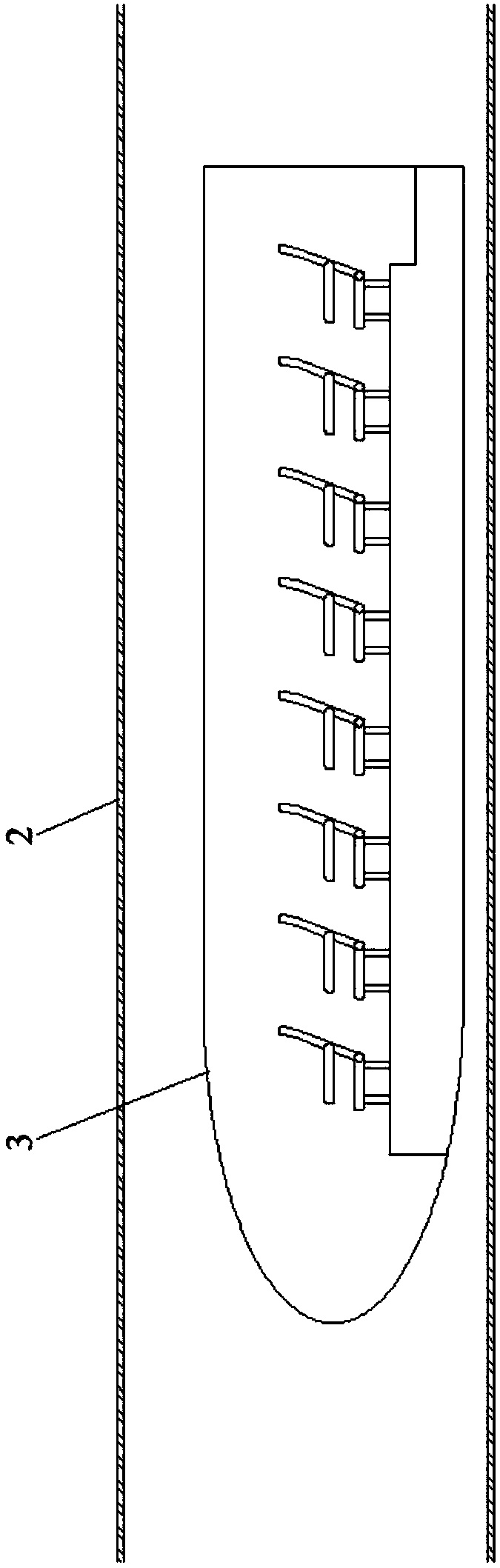

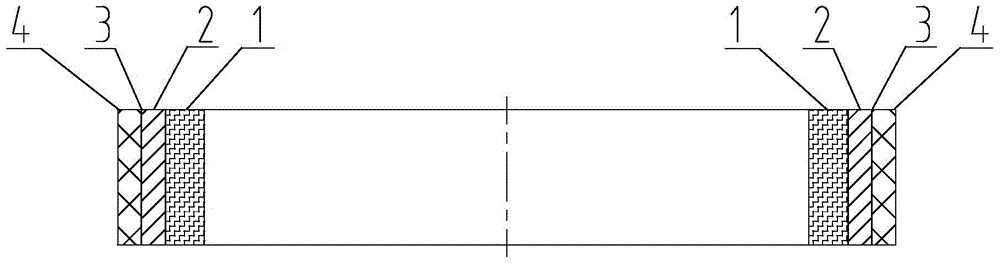

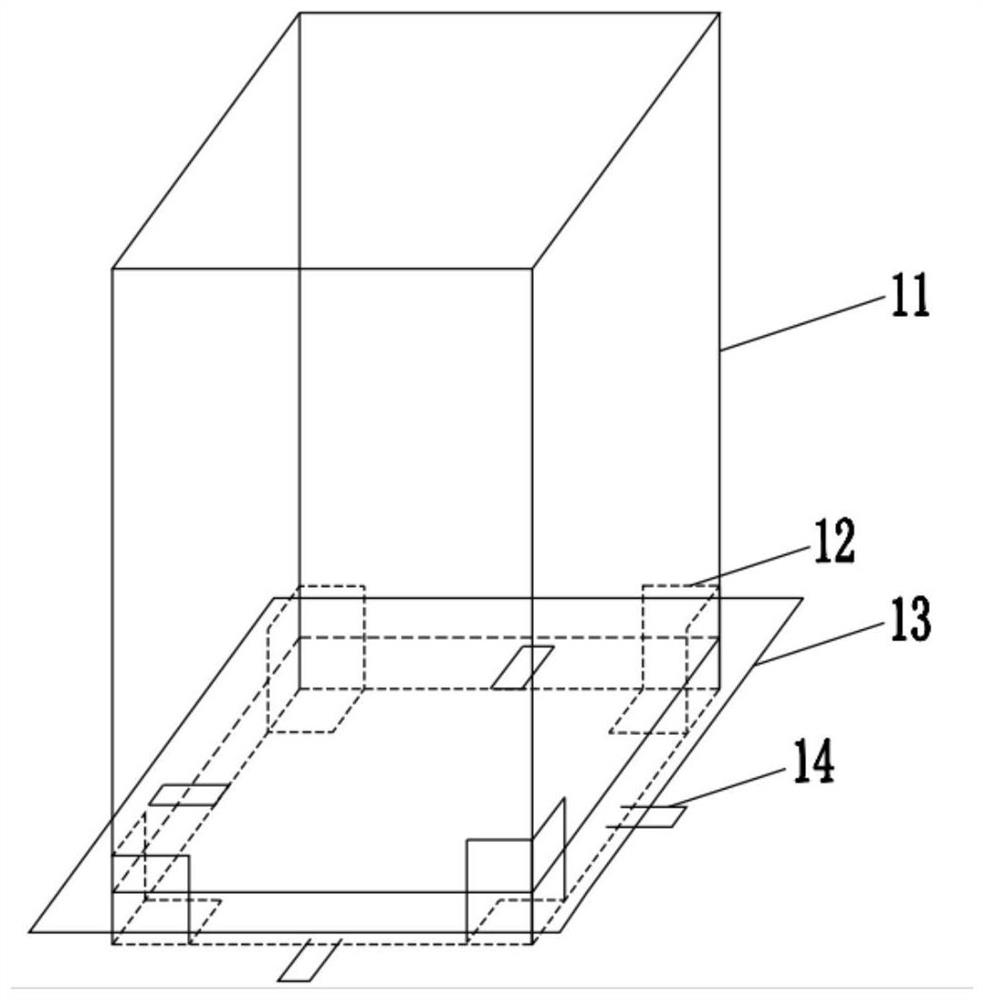

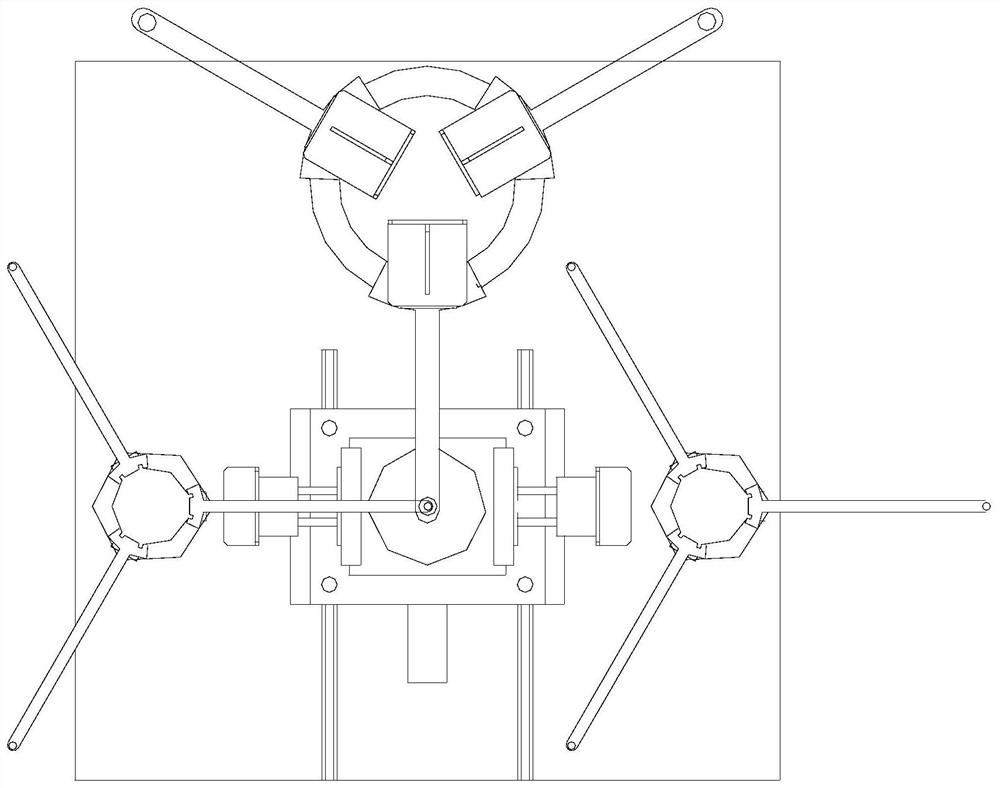

Connection joint and installation method of fabricated circular steel tube casing fiber concrete column

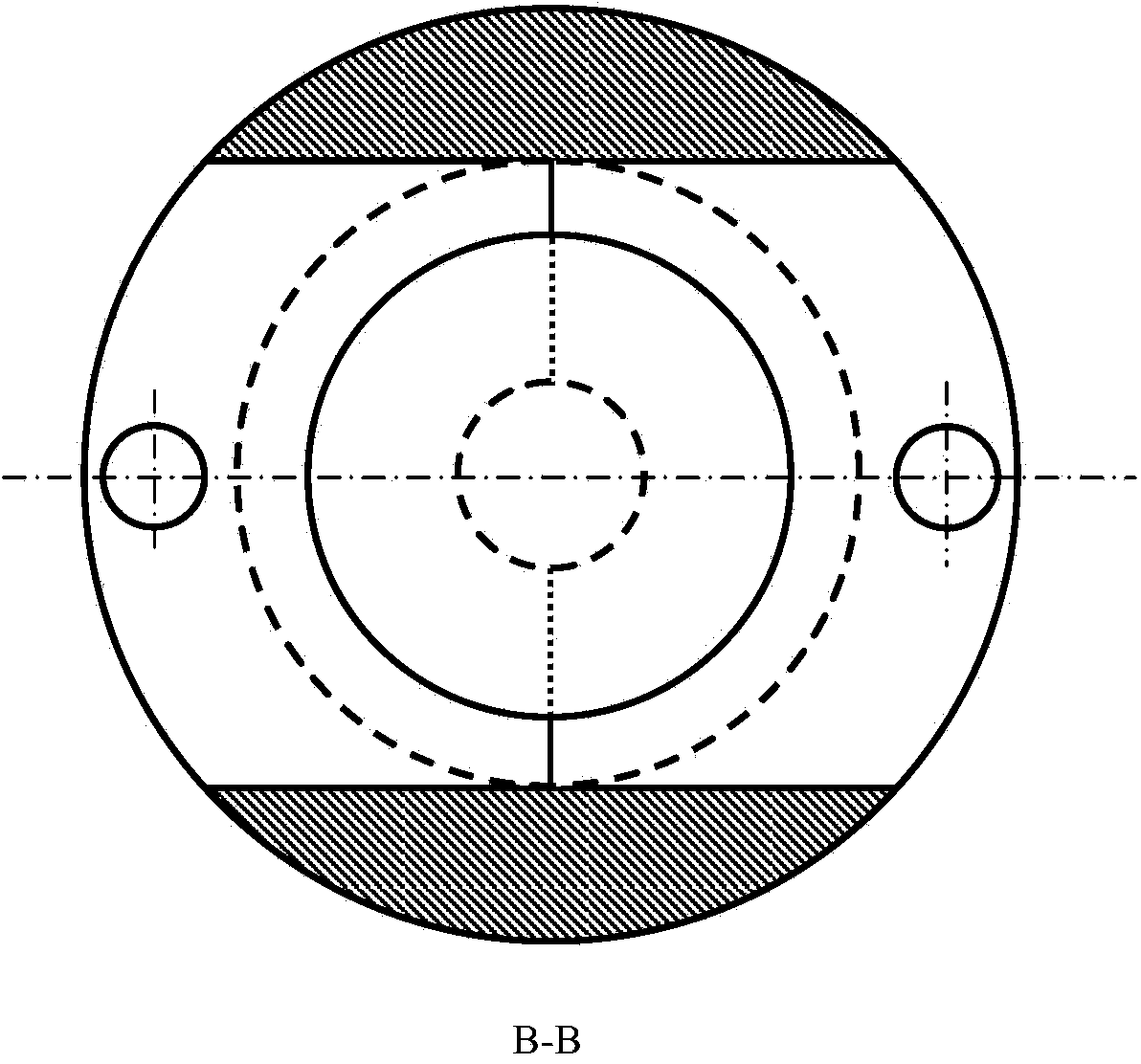

The invention relates to the technical field of structural engineering, and discloses a connection joint of a fabricated circular steel tube casing fiber concrete column. The connection joint of the fabricated circular steel tube casing fiber concrete column comprises an outer-wrapped high-strength circular steel pipe, an inner sleeve high-strength round steel pipe and a circular casing conversion splitter plate, wherein wedge-shaped connecting teeth are arranged at the two ends of the outer-wrapped high-strength round steel pipe and the inner sleeve high-strength round steel pipe, the wedge-shaped connecting teeth are uncontinuously and evenly distributed along the circumference. The circular casing conversion splitter plate comprises a circular plate. A center through-hole is formed in the central position of the circular plate, the upper and lower faces of the circular plate are provided with vertical partition boards, each vertical partition board is provided with wedge-shaped chutes matched with the wedge-shaped connecting teeth, and the steel pipe and the circular casing conversion splitter plate are fixedly connected by the coordination between the wedge-shaped connecting teeth and the wedge-shaped chutes. According the connection joint and installation method of fabricated circular steel tube casing fiber concrete column, field welding between high-strength circular steel pipes is avoided, the reliability of the joint is improved, the steel part of the whole joint is produced by a factory and is assembled on the site, the concrete is poured on the site, and the influence of the construction on the quality is furthest minimized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

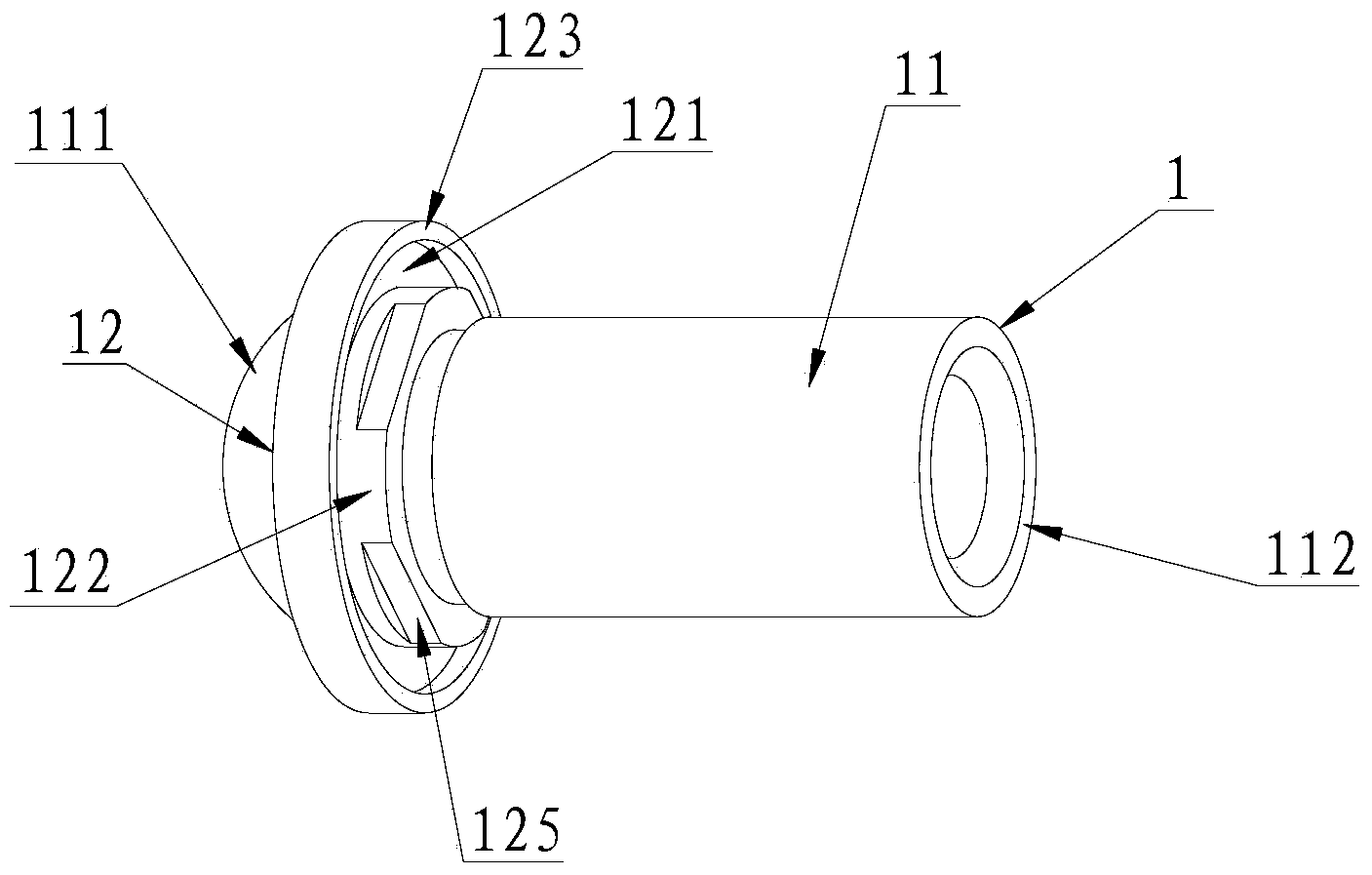

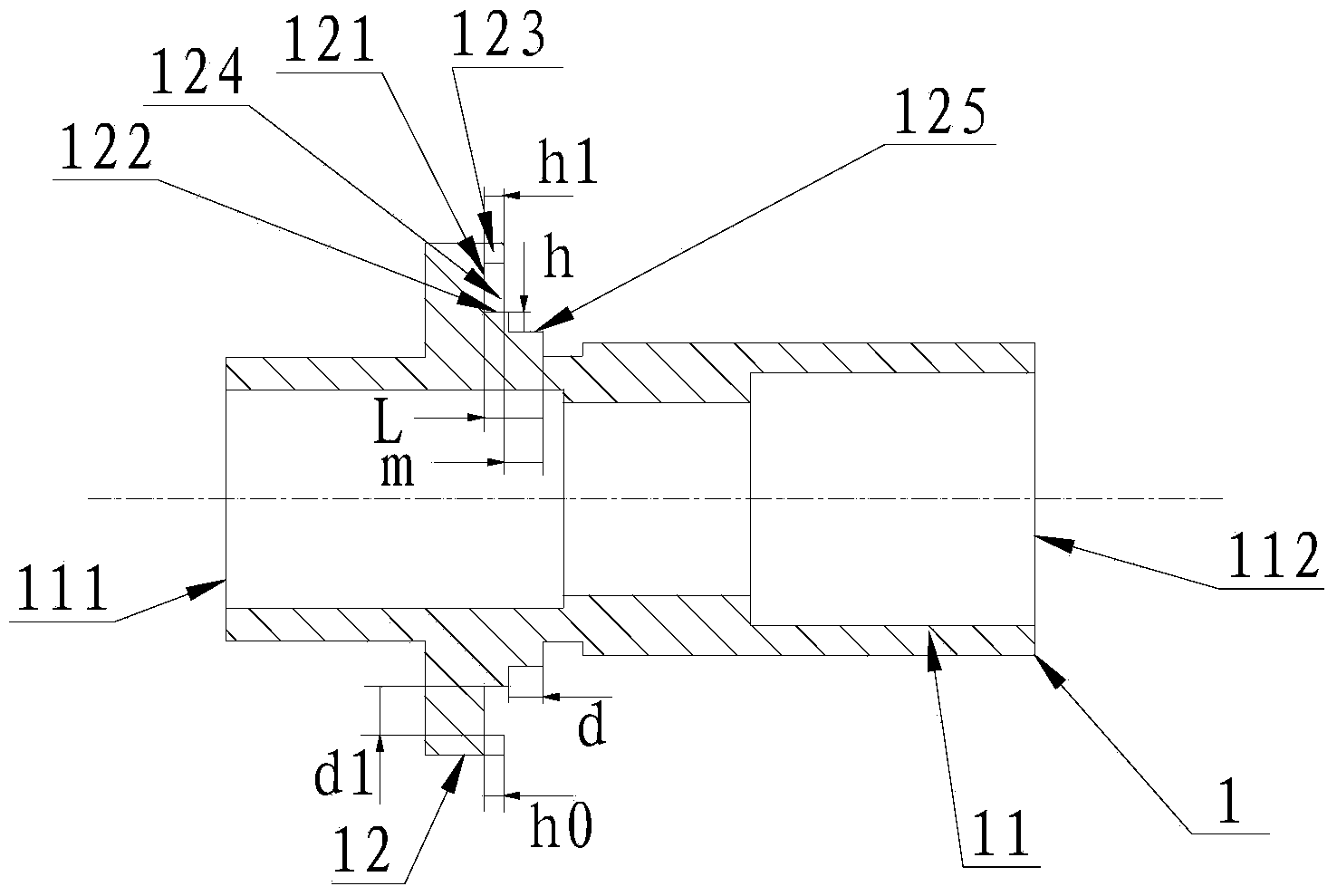

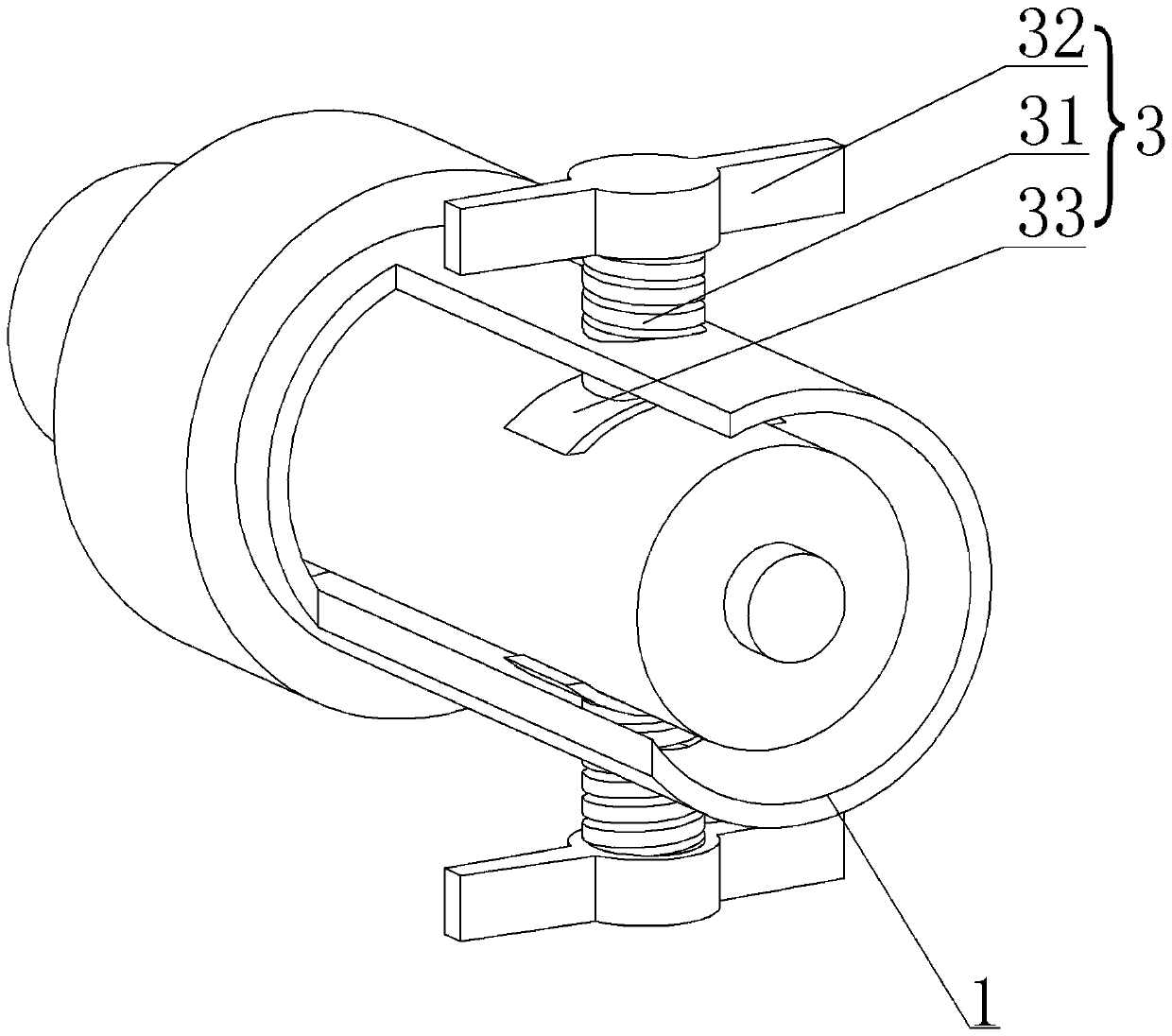

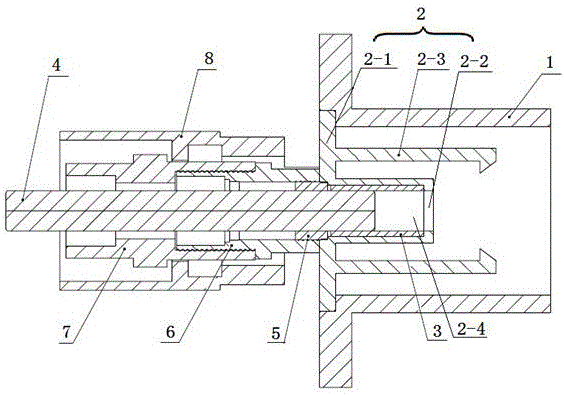

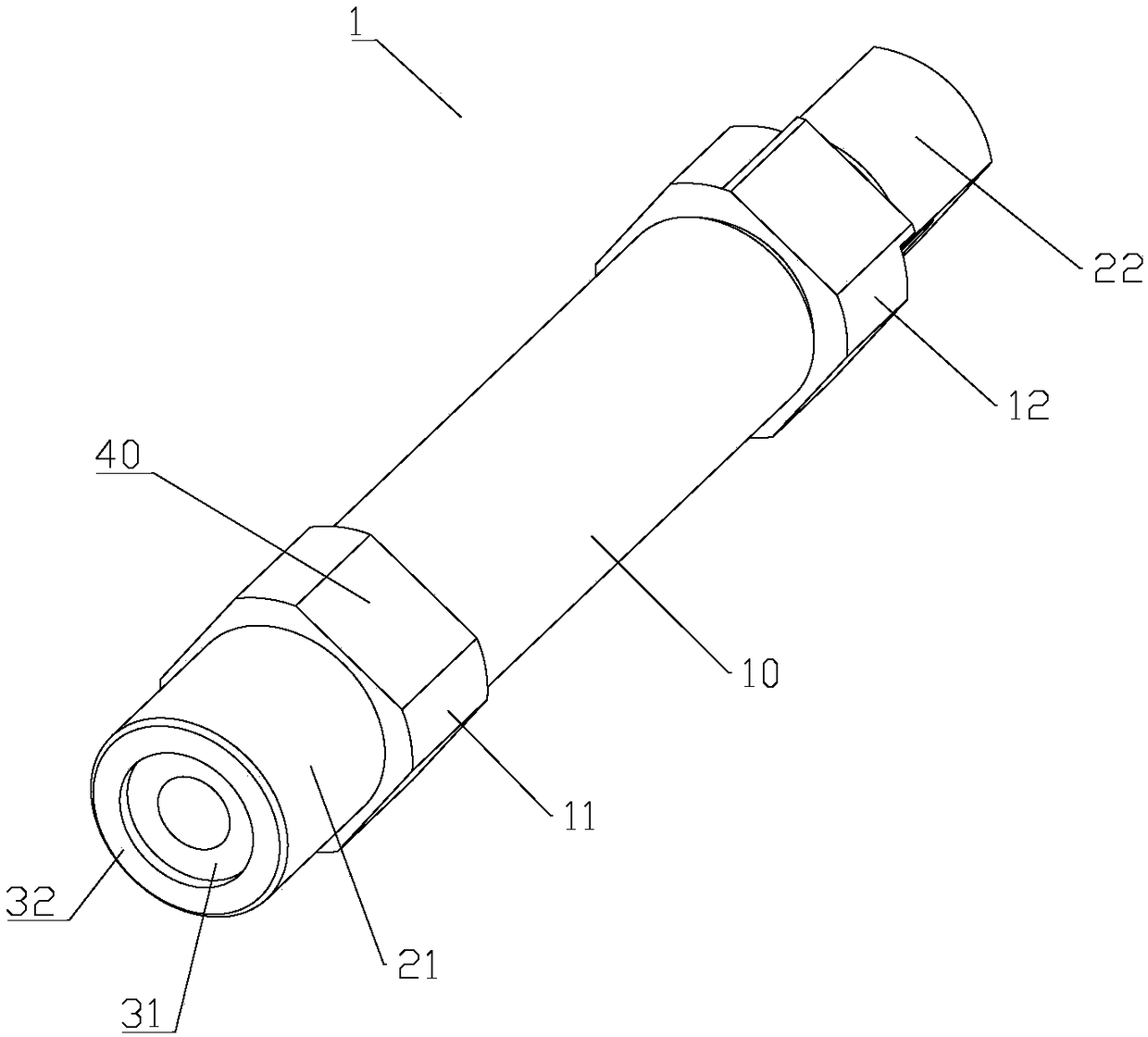

Connecting and sealing structure of valve body and gas cylinder

InactiveCN103244823AApplicable connectionSuitable for sealed connectionEngine sealsContainer filling methodsGas cylinderProduct gas

The invention relates to a connecting and sealing structure of a valve body and a gas cylinder, which is suitable for sealing connection between all gas cylinders and valve bodies, and is particularly suitable for sealing connection between a gas cylinder with a gas pressure of higher than 20MPa and a valve body. The sealing structure and the valve body are manufactured into an integral body in advance, the inner side of a gas cylinder port is matched with a conical surface structure and a screw structure of the connecting and sealing structure, the valve body is connected with the gas cylinder through the screw structure, and the complete sealing connection between the valve body and the gas cylinder is realized through two soft seals and two hard seals. The connecting and sealing structure can be used in an application environment area with large difference in temperature, and can be used for the sealing connection between the valve bodies and the gas cylinders, which are made of different materials.

Owner:BEIJING JONTON HYDROGEN TECH

Single-faced and double-thread composite material sewing device

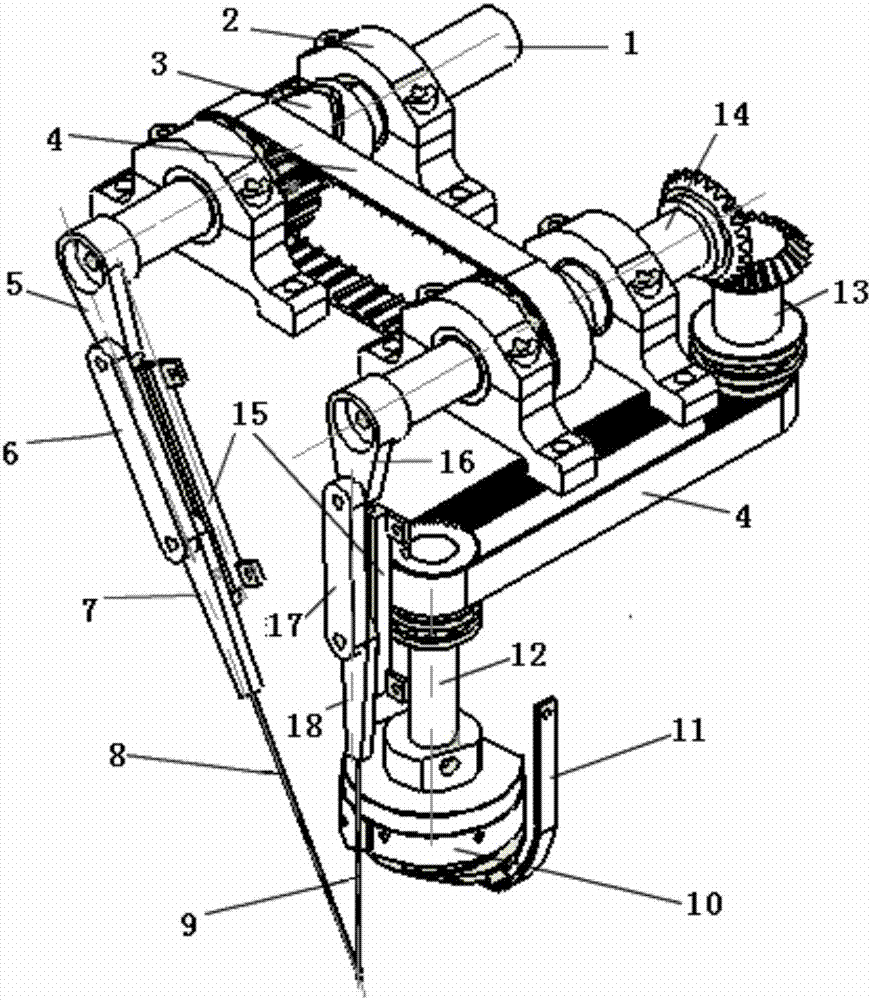

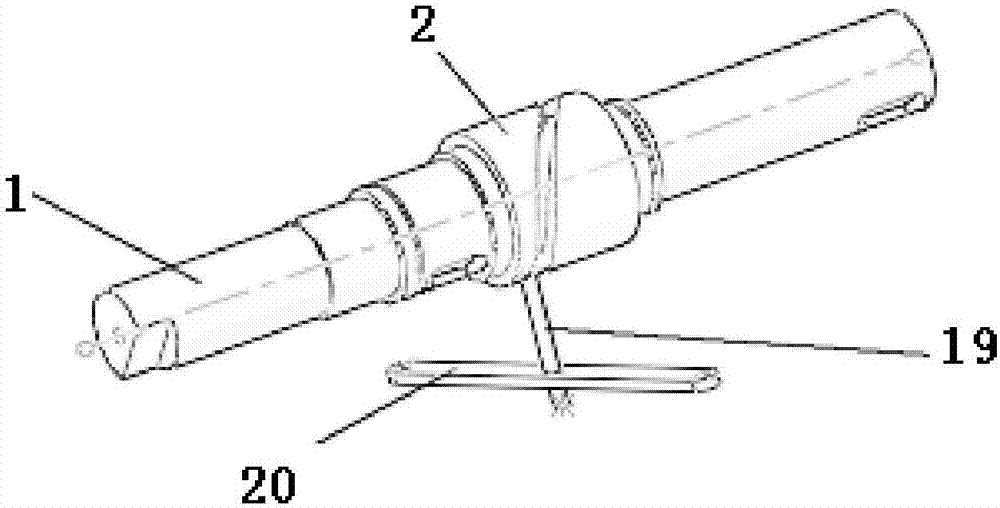

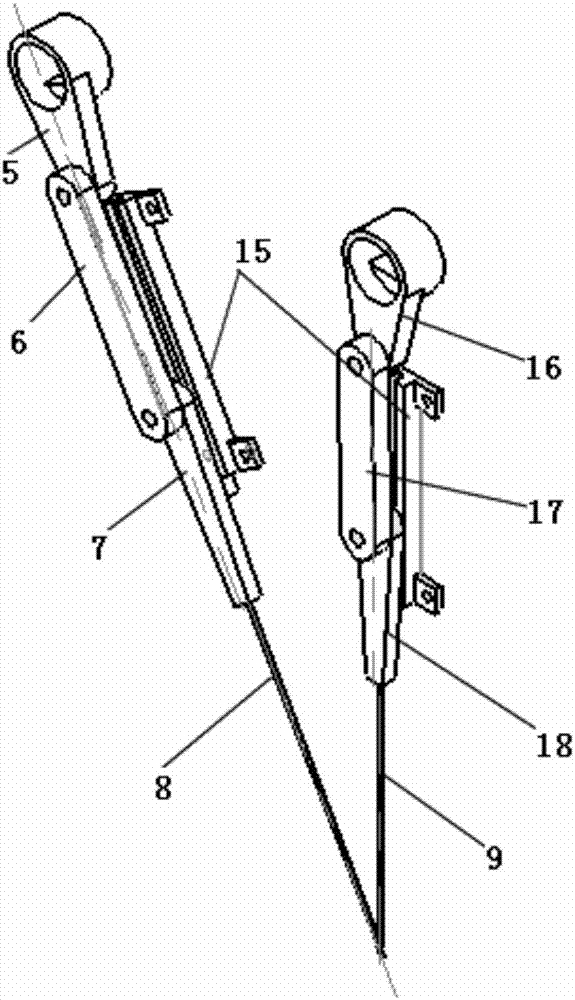

The invention relates to a single-faced and double-thread composite material sewing device which comprises a thread pulling rod, a rotating shuttle, a thread guiding needle and a thread taking-up needle. When the thread guiding needle and the thread taking-up needle move to reach a lower limit, the thread guiding needle and the thread taking-up needle are intersected, and the thread taking-up needle is inserted into the space between an upper thread and the thread guiding needle through an oblique plane; when the thread guiding needle and the thread taking-up needle move to reach an upper limit, a hook groove takes up an upper thread loop, and a shuttle point reaches the position below the thread taking-up needle to hook the upper thread loop; when the shuttle point drives the upper thread loop to rotate for one circle and lock a bottom thread, the thread guiding needle and the thread taking-up needle firstly move downward and then upward move, the thread pulling rod firstly pays off a thread through forward swing and then pulls the thread through backward swing. The device can conduct single-faced sewing on a fiber laid composite material product provided with a complicated appearance curved surface or a plane having a certain thickness and form locked stitches on the surface, the formed stitches are smooth and free of thread knots, and a structure is stable and reliable.

Owner:WUHAN UNIV OF TECH

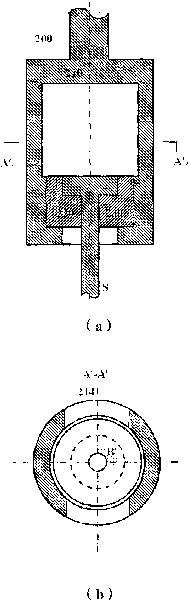

Vacuum oil tubing coupling

InactiveCN101832108ASimple structureReduce manufacturing costDrilling rodsDrilling casingsCouplingThermal insulation

The invention relates to a vacuum oil tubing coupling which comprises a coupling body and an outer sleeve, wherein the coupling body is cylindrical, conical holes which are large outside and small inside are arranged at two ends of the inner surface of the coupling body, and screw threads are arranged on the inner surface of each conical hole, wherein the outer sleeve is sleeved on the outer surface of the coupling body, and a closed vacuum layer is arranged between the outer surface of the coupling body and the inner surface of the outer sleeve. In the invention, the outer sleeve is sleeved on the outer surface of the coupling body, and a clearance between the coupling body and the outer sleeve forms the closed vacuum layer, therefore, the thermal insulation property of the vacuum oil tubing coupling is enhanced; when the coupling is used, two vacuum composite heat-insulation pipes are respectively screwed into threaded conical holes at two ends of an inner hole of the coupling, and the threaded conical holes enhance the sealing property between the coupling and the vacuum composite heat-insulation pipes. In addition, the coupling has the advantages of simple structure, low production cost and long service life.

Owner:湖北守能真空科技有限公司

High temperature brazing filler metal for brazing non-oxide ceramic and composite material as well as preparation method of high temperature brazing filler metal

ActiveCN102699573ARight melting pointLow melting pointWelding/cutting media/materialsGrain treatmentsNon oxide ceramicsMass ratio

The invention provides a high temperature brazing filler metal for brazing a non-oxide ceramic and a composite material as well as a preparation method of the high temperature brazing filler metal, relating to a high temperature brazing filler metal and a preparation method thereof. The invention aims to solve a problem that the property of the high temperature brazing filler metal in the traditional welding joint between the non-oxide ceramic and the composite material is unreliable at more than 500 DEG C. According to the invention, the high temperature brazing filler metal comprises the following components in parts by weight: 47-52 parts of Ni, 25-28 parts of Cr,18-21 parts of Nb, 0-2 parts of B, 0-2 parts of Ti and 0-6 parts of W; and the preparation method comprises the following steps of: (1) weighing the components and mixing the components to obtain a mixed material; and (2) putting the mixed material into a grinding ball according to a ball material mass ratio of (8-20):1, intermittently ball-milling the mixed material for 4-20 h at a speed of 250-350 r / min to reach a filler ratio of 45-55%, so as to obtain the high temperature brazing filler metal. The shear strengths of the joint obtained according to the invention at room temperature and high temperature of 800 DEG C are respectively 18-48 MPa and 11-27 MPa. The high temperature brazing filler metal for brazing the non-oxide ceramic and the composite material as well as the preparation method of the high temperature brazing filler metal, provided by the invention, are applied to the aerospace field.

Owner:HARBIN INST OF TECH

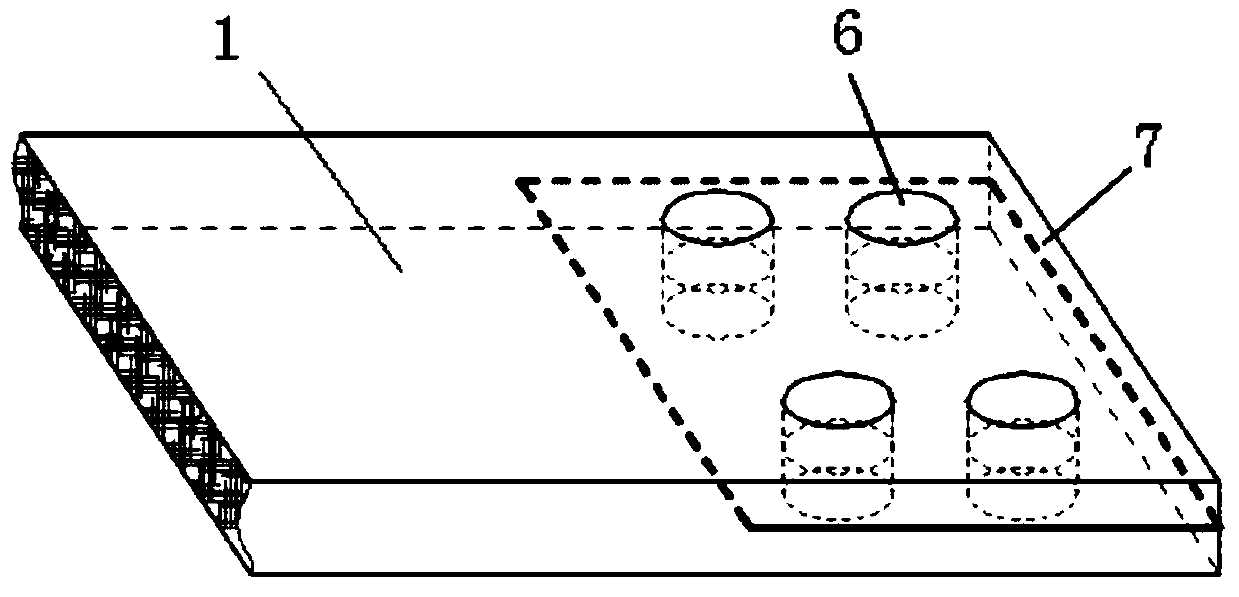

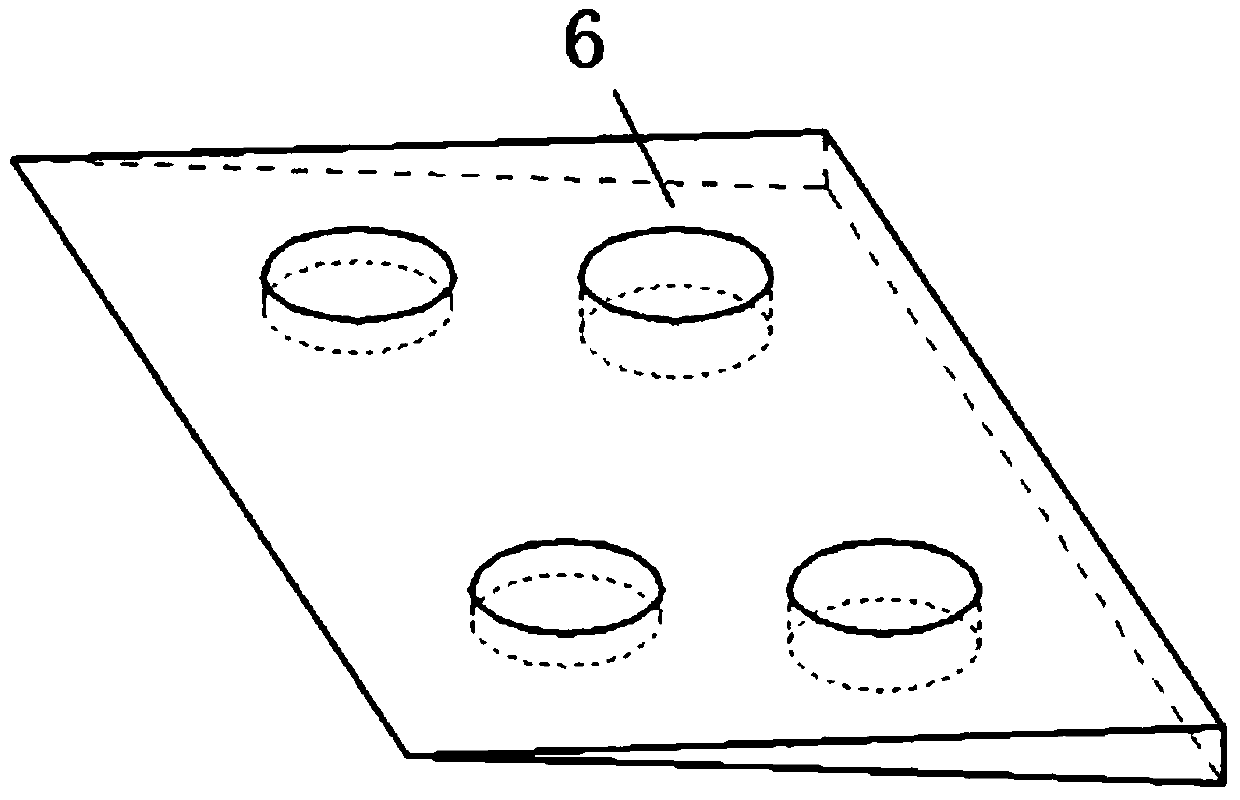

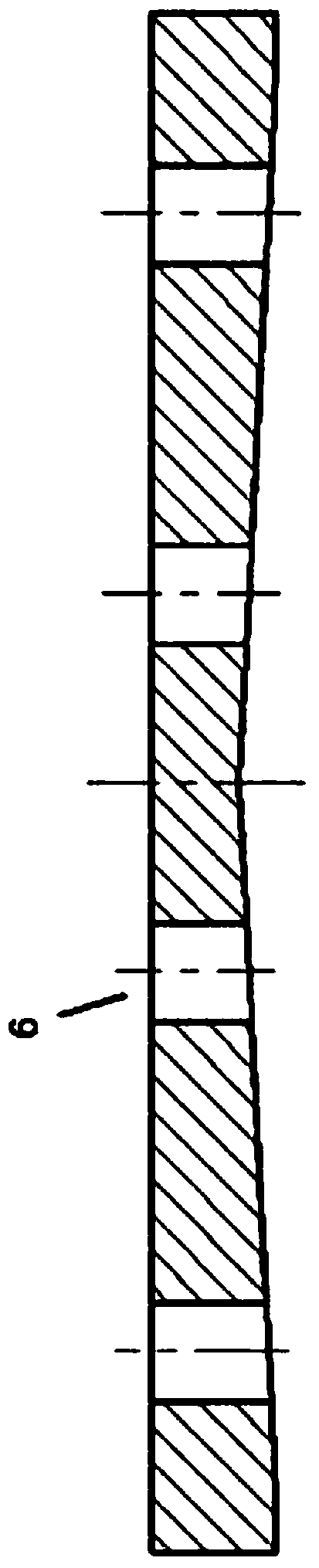

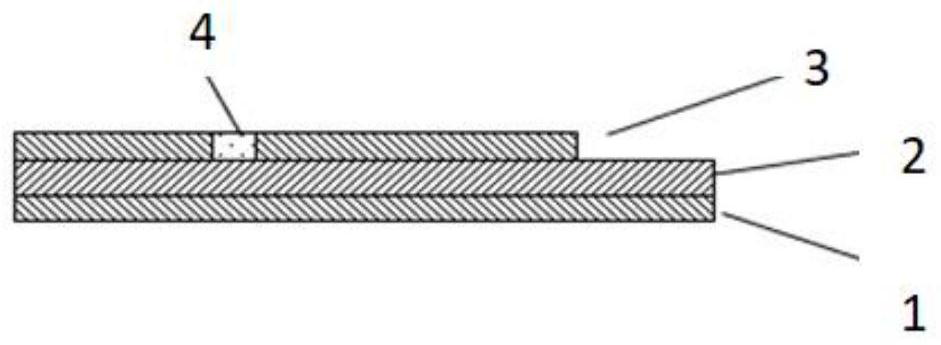

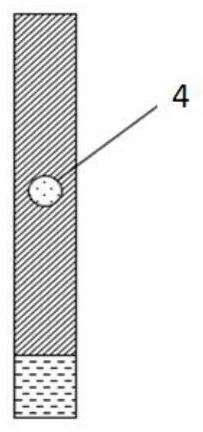

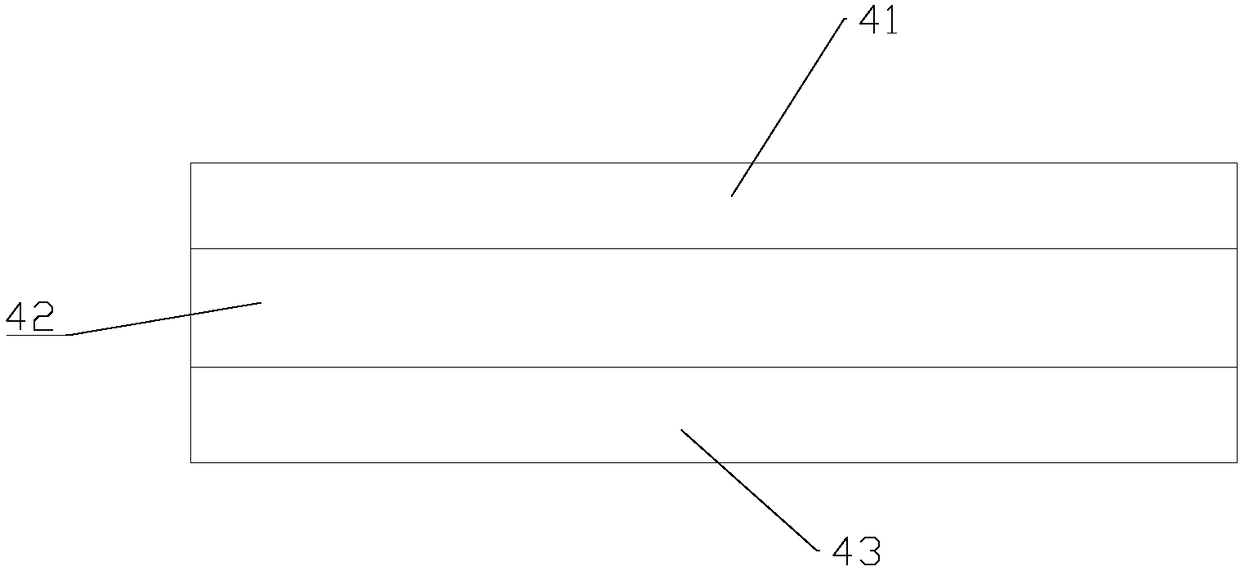

Composite-material plate joint

InactiveCN104832507AApplicable connectionVersatileSheet joiningUltimate tensile strengthStructural safety

Disclosed in the invention is a composite-material plate joint comprising a composite-material plate, a metal wedge block, and connecting plates. Connecting holes are formed in corresponding parts of the end portion of the composite-material plate, the metal wedge block, and the connecting plate. A gap is processed in the edge of the composite-material plate; and the metal wedge block is wedged into the gap. One side, has the same gradient as the metal wedge block, of each connecting plate is buckled at each of the two sides of the composite-material plate; and the connecting plates and the composite-material plate wedged into the metal wedge block are fixedly connected by bolts and nuts. The composite-material plate joint has the following advantages: the joint can be applied to connection between the composite-material plates with different materials and different heights and between the composite-material plate and other metal components and has high universality, economy, and adaptability. Moreover, the process is simple; the implementation is flexible; the mounting and dismounting become convenient; and the tensile strength is high and the structure is safe and reliable.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

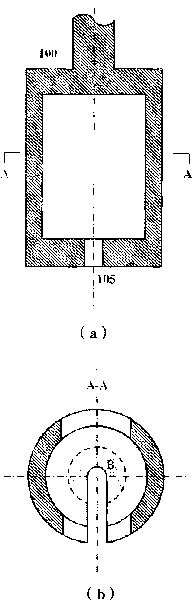

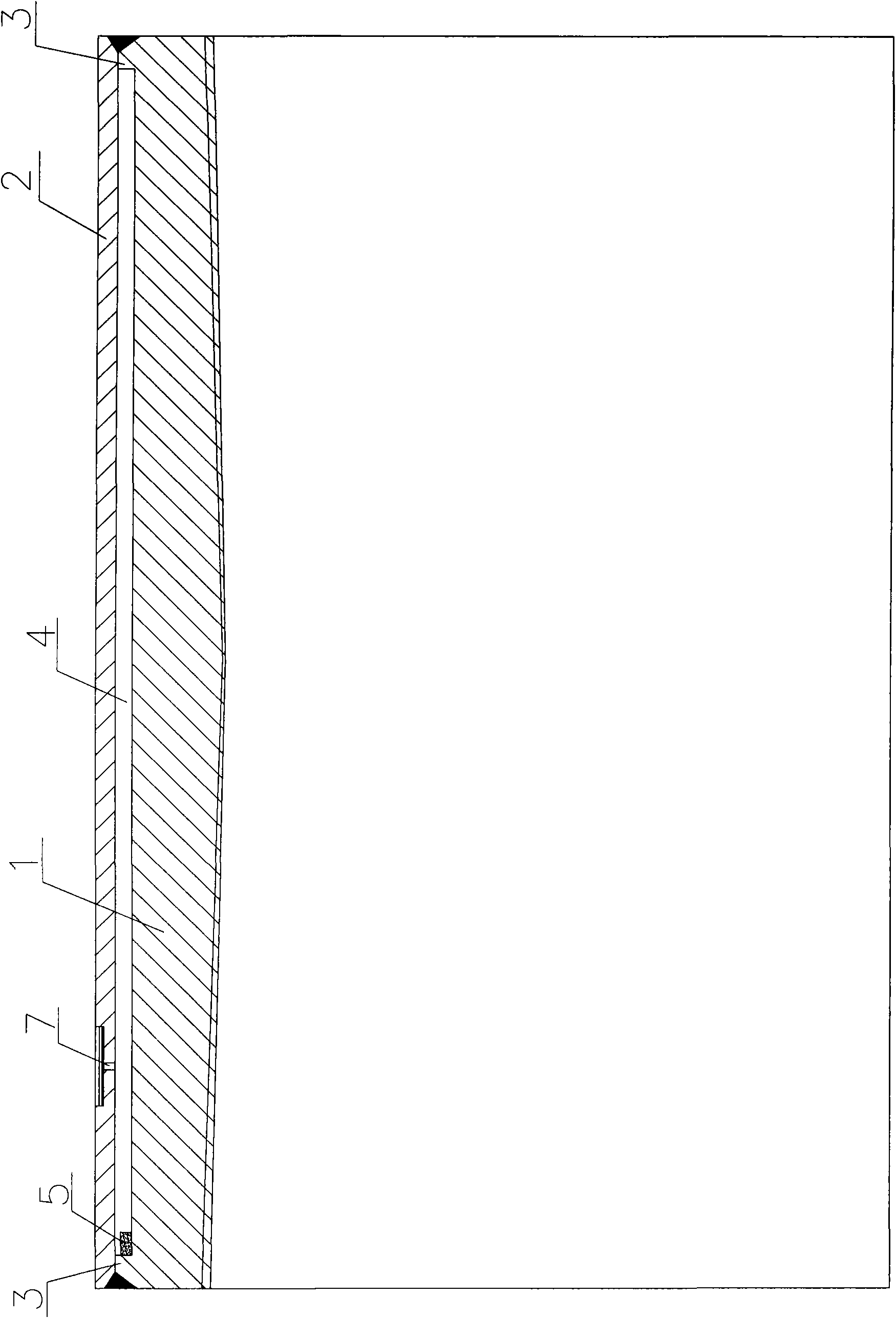

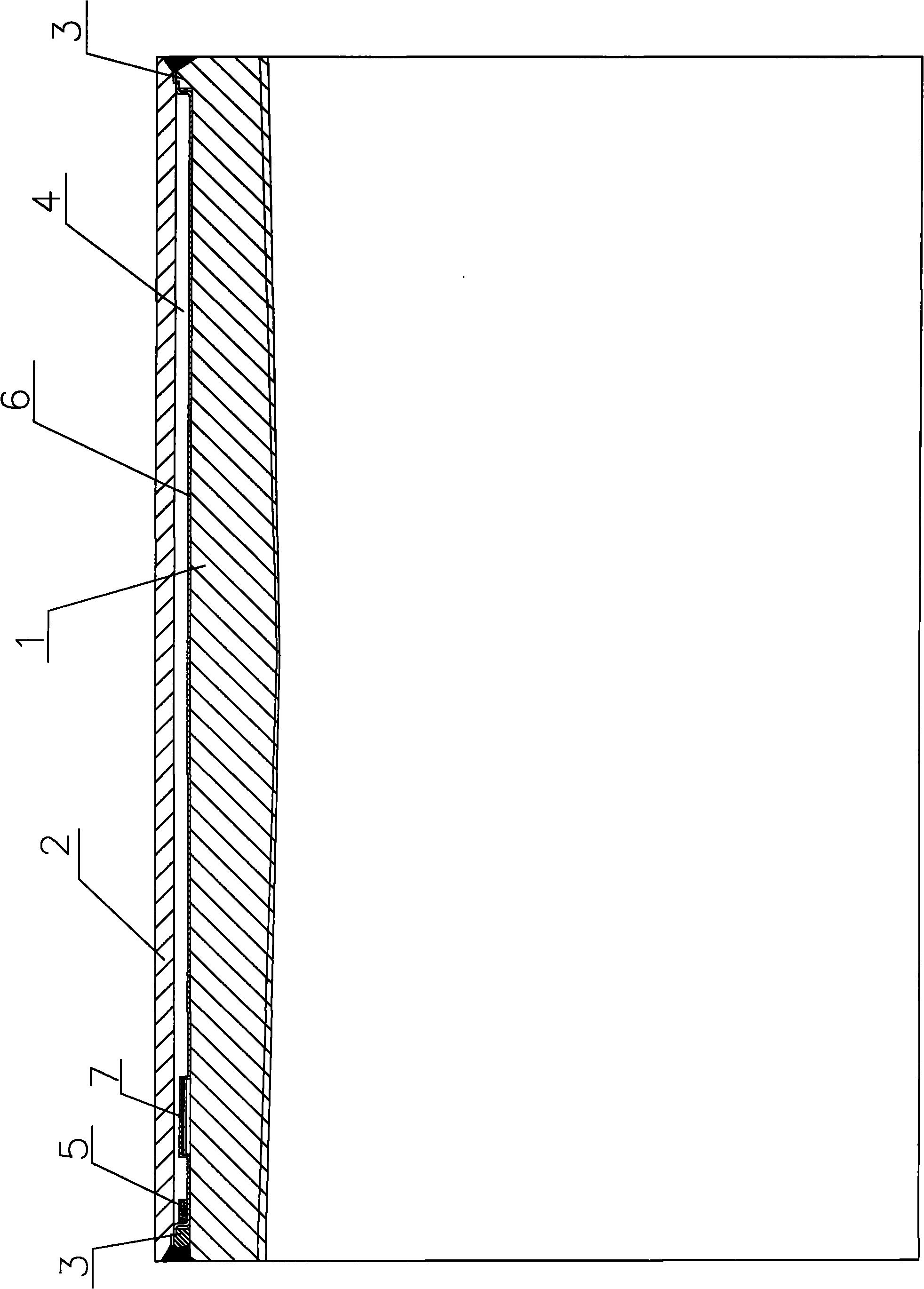

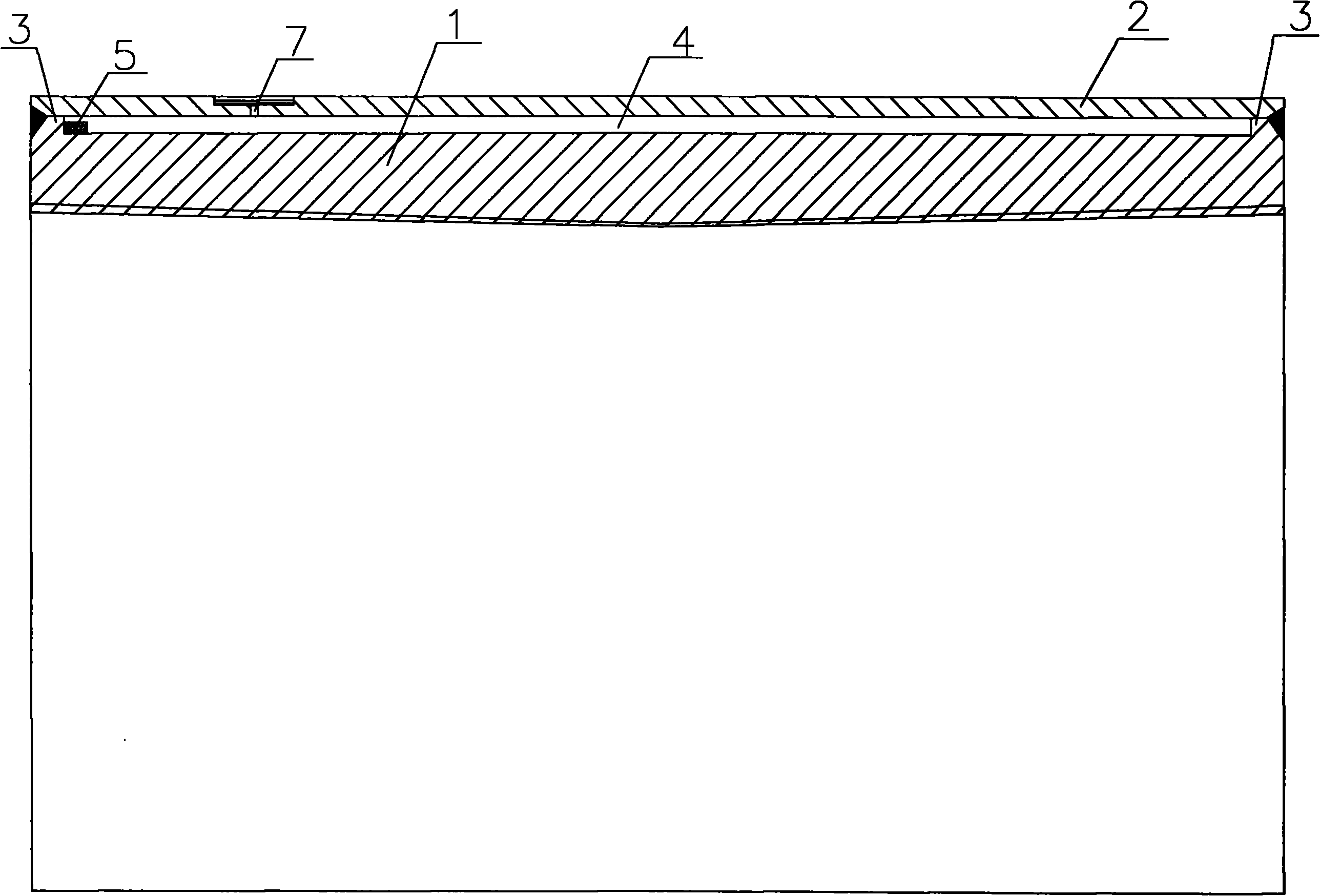

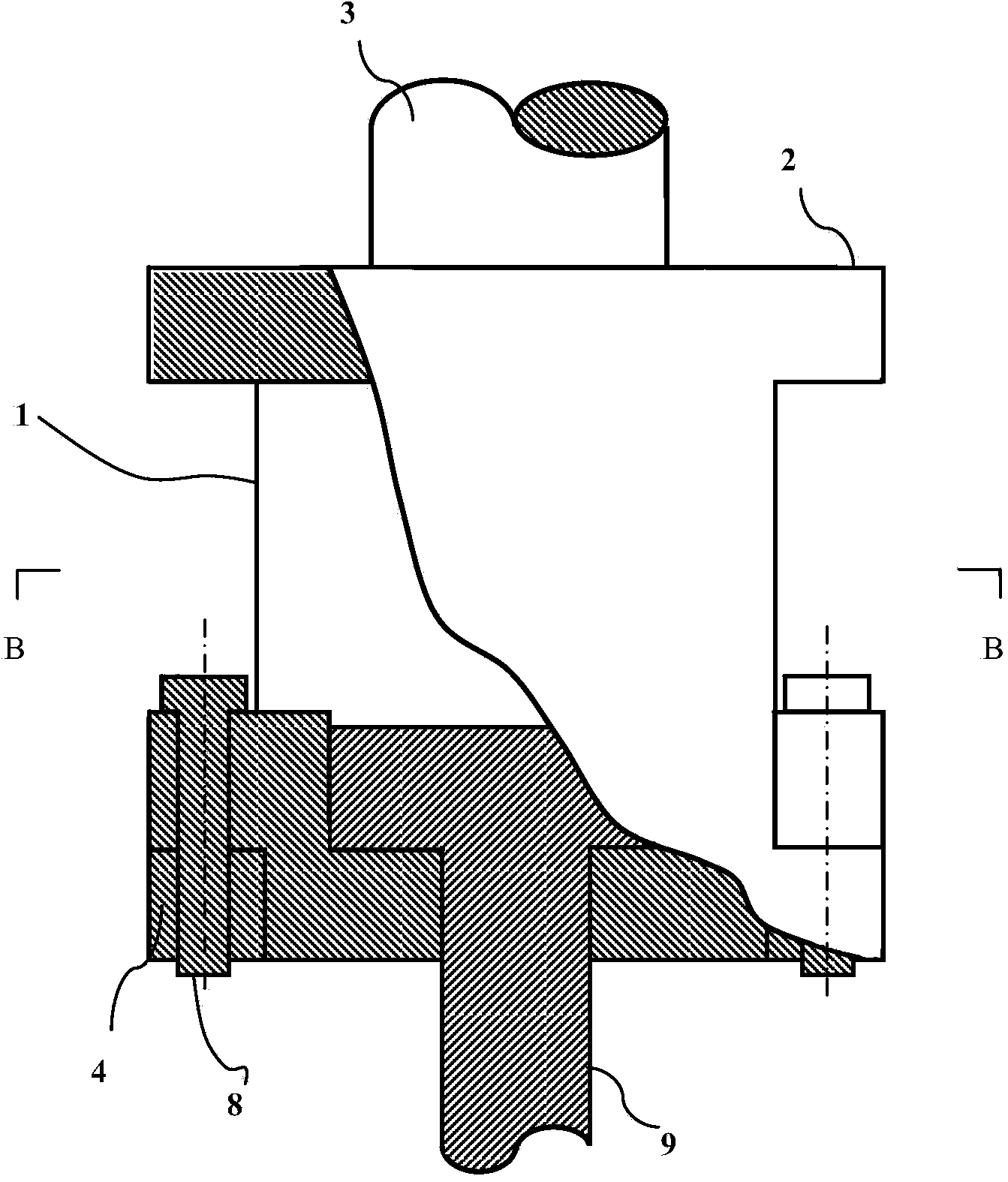

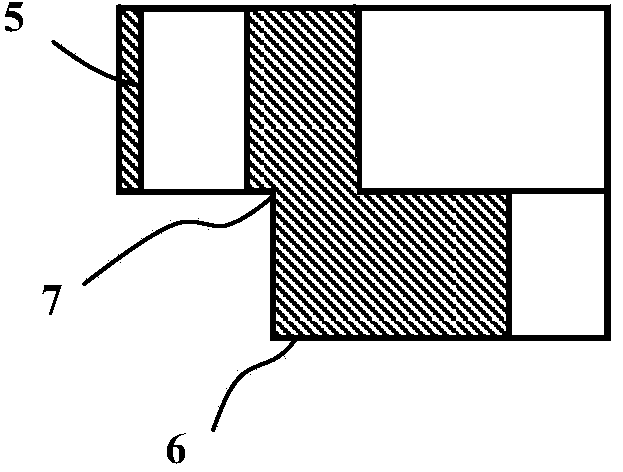

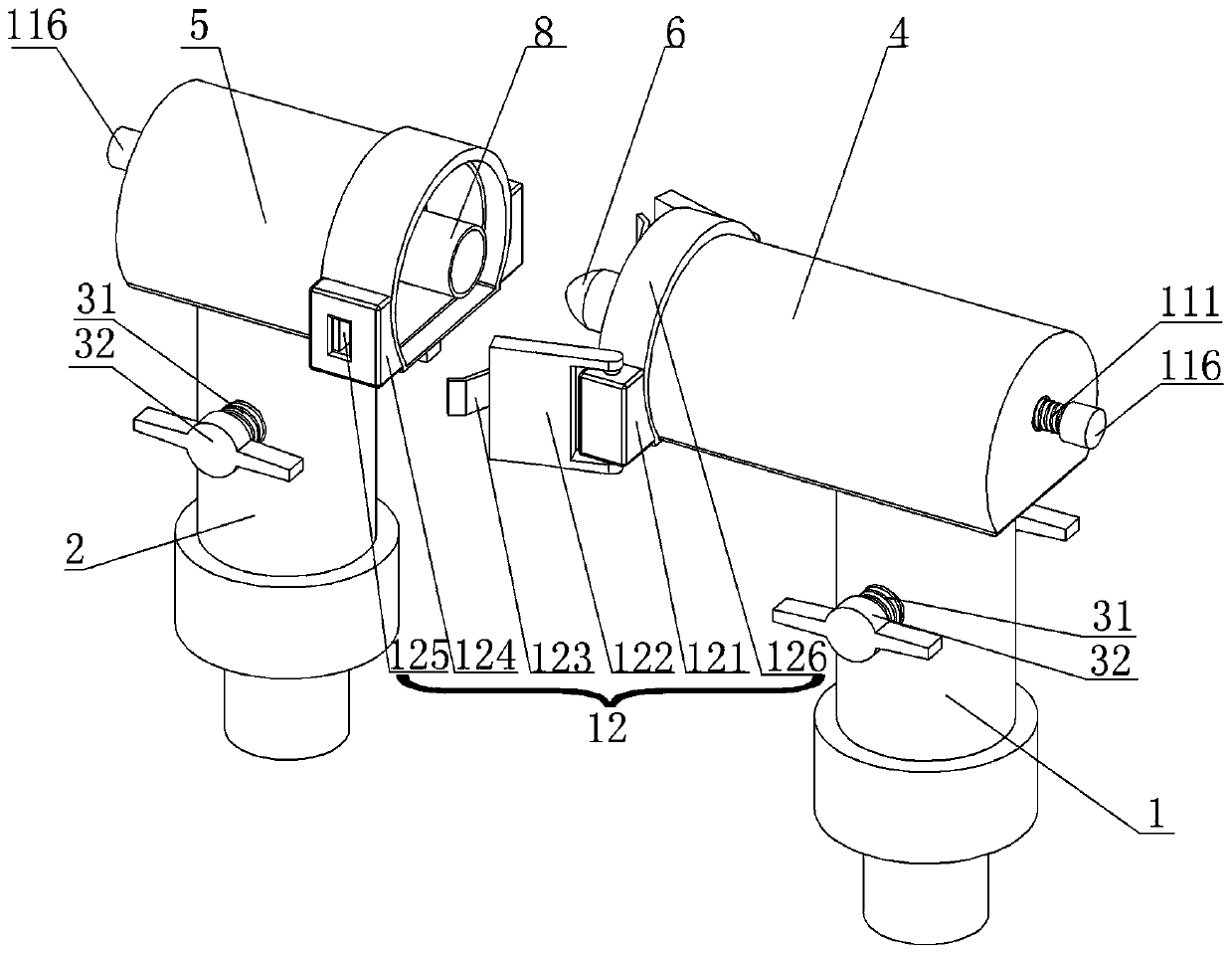

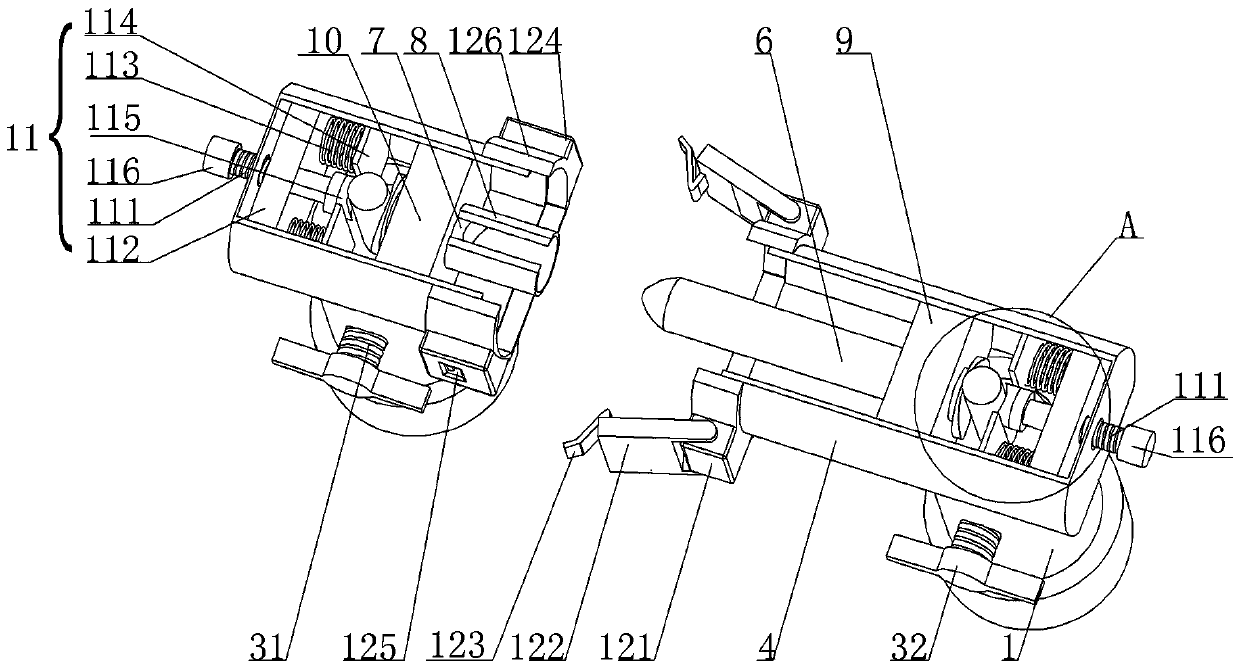

Long-time creep fixture

The invention provides a long-time creep fixture, comprising a cylindrical fixture body and two arc-segment-like seat covers with a same structure, wherein the cylindrical fixture body is connected with a tester and bears tensile load from the tester, two radial sides of the fixture body are respectively provided with a column (1) which has an arc-segment-like outer side surface, the inner side surface of each of the columns (1) is a plane perpendicular to the radial direction, the upper ends of the columns (1) are connected with the upper cover (2) of the fixture body so as to form an integral body, the upper part of the upper cover (2) is a solid cylinder (3) connected with the tester, the lower ends of the columns (1) are connected with a circular ring body (4) located at the bottom of the fixture body so as to form an integral body, each of the two arc-segment-like seat covers comprises a larger-diameter arc upper edge (5) and a smaller-diameter arc lower edge (6), and the arc upper edge (5) and the arc lower edge (6) are stagger and are connected through an arc cylinder, which enables the longitudinal section of the seat cover to form a zigzag shape. The long-time creep fixture prevents adhesion between the fixture and a specimen, realizes uniform loading and helps to reduce cost of testing.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Power cable joint

PendingCN110932019AQuick clampingRelax quicklyCoupling contact membersTwo-part coupling devicesPower cableControl theory

The invention discloses a power cable joint. The power cable joint includes a first connecting pipe and a second connecting pipe which are used for enabling two cables to extend into respectively, fixing devices which are fixedly arranged on the first connecting pipe and the second connecting pipe respectively and used for fixing the corresponding cables, and a first connector and a second connector which are used for enabling electricity cores of the two cables to extend into respectively and be connected, wherein the first connecting pipe is communicated with the first connector, and the second connecting pipe is communicated with the second connector; and the power cable joint also includes a locking device which is used for detachably connecting the first connector and the second connector. The power cable joint is high in safety coefficient, high in stability, easy to use, capable of rapidly detaching and installing the two ends of a cable, convenient to overhaul and test and suitable for connection of power cables.

Owner:中国电建集团河北工程有限公司

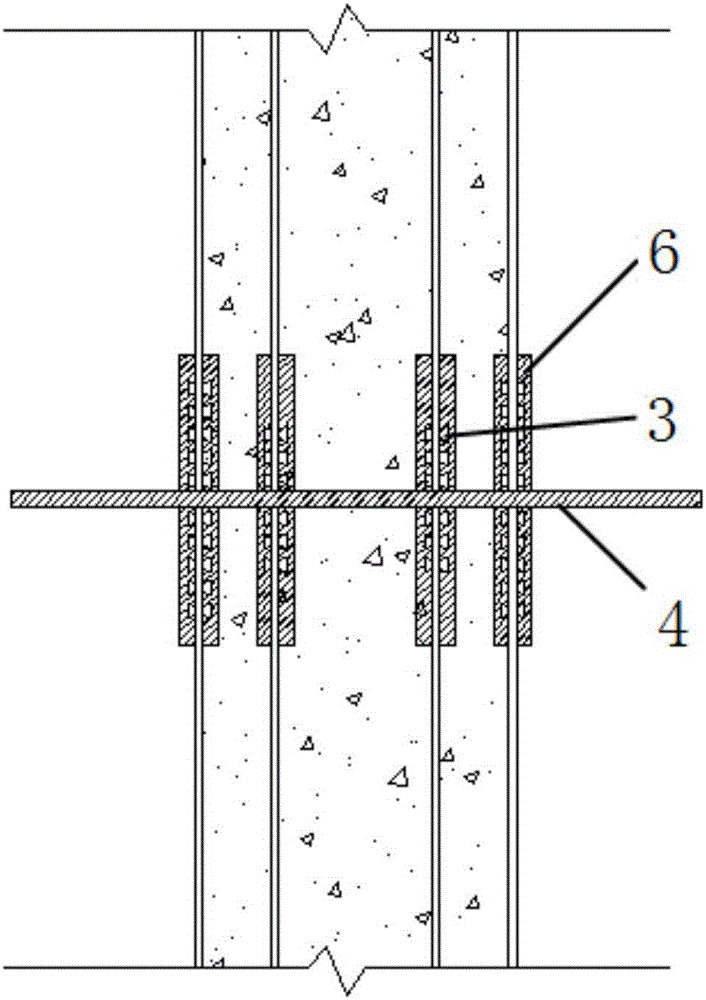

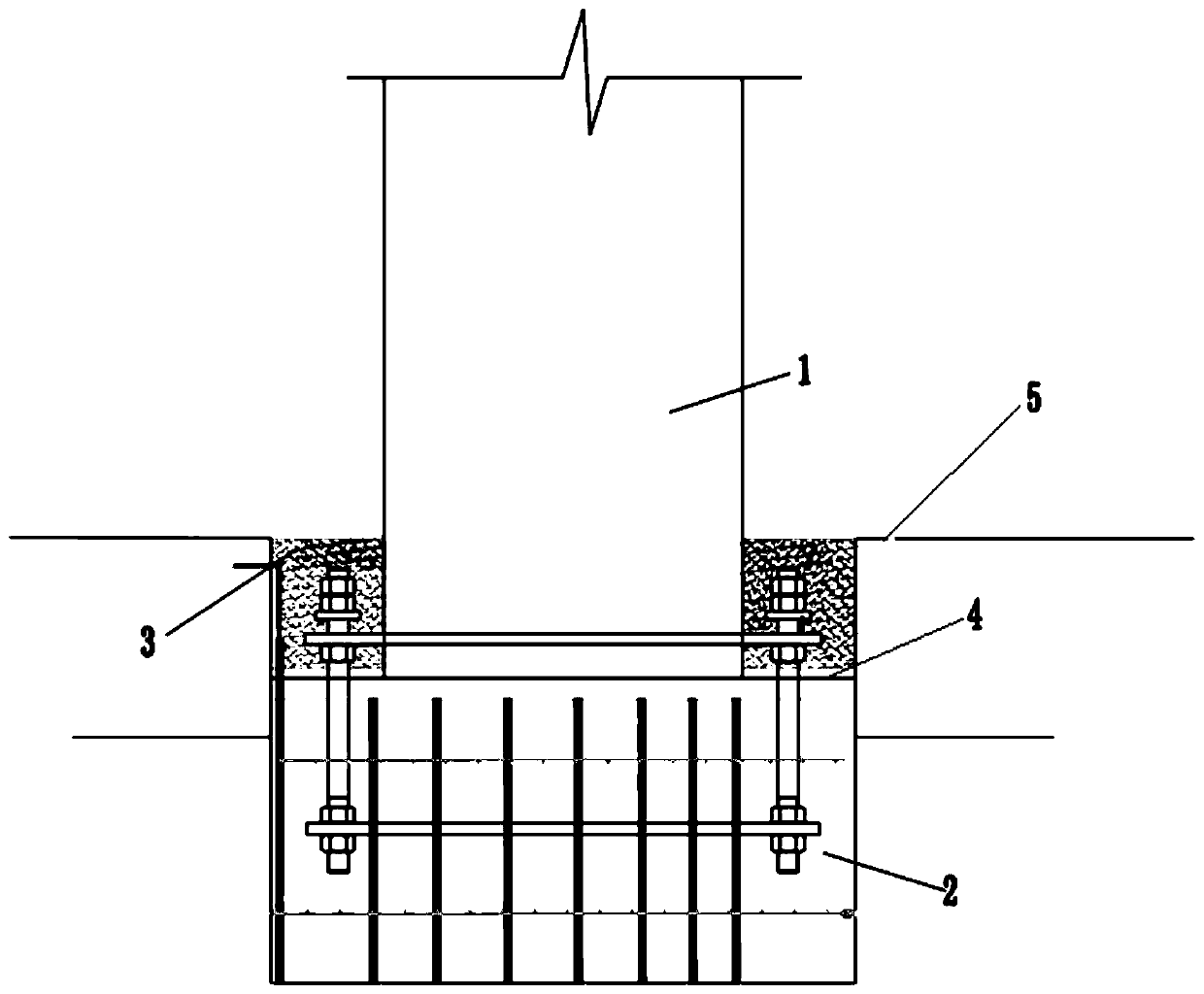

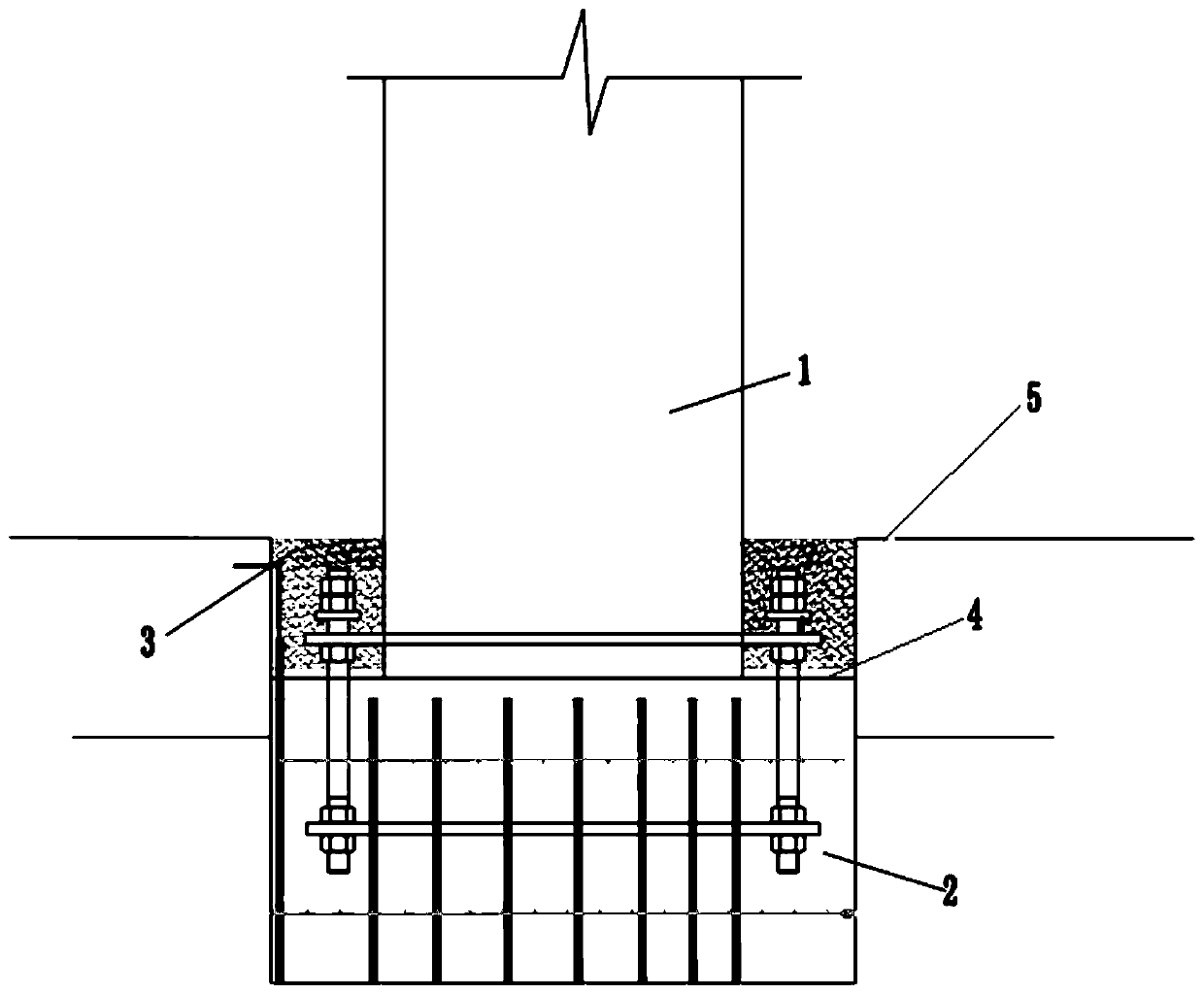

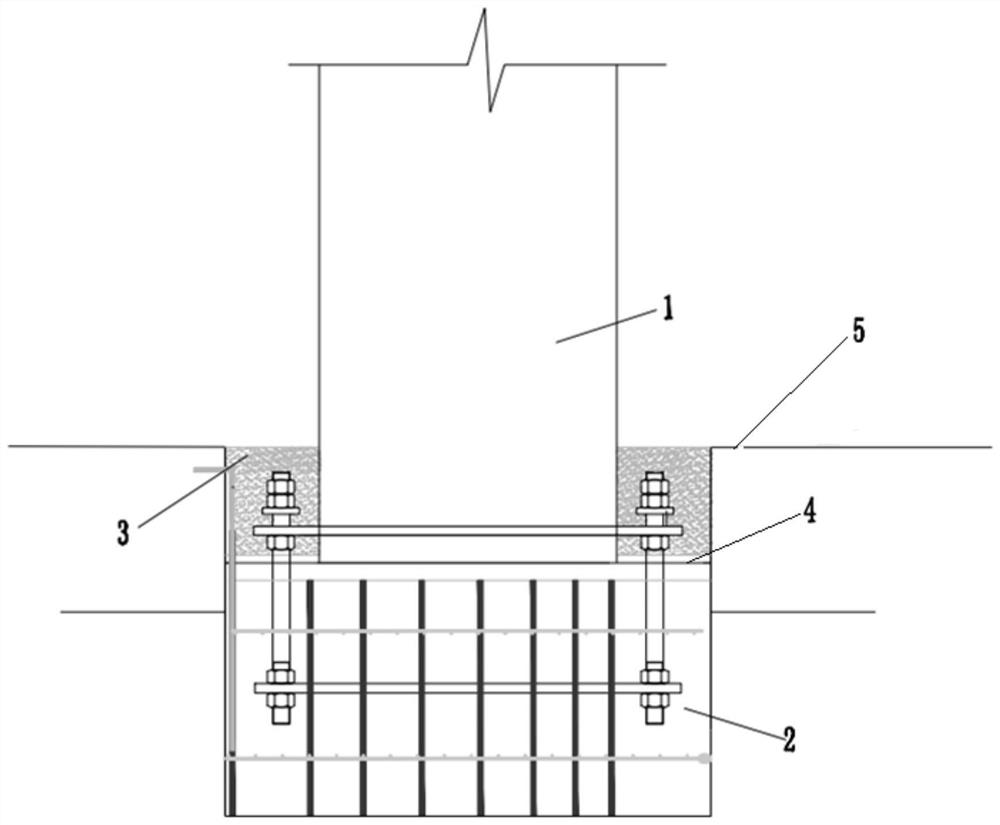

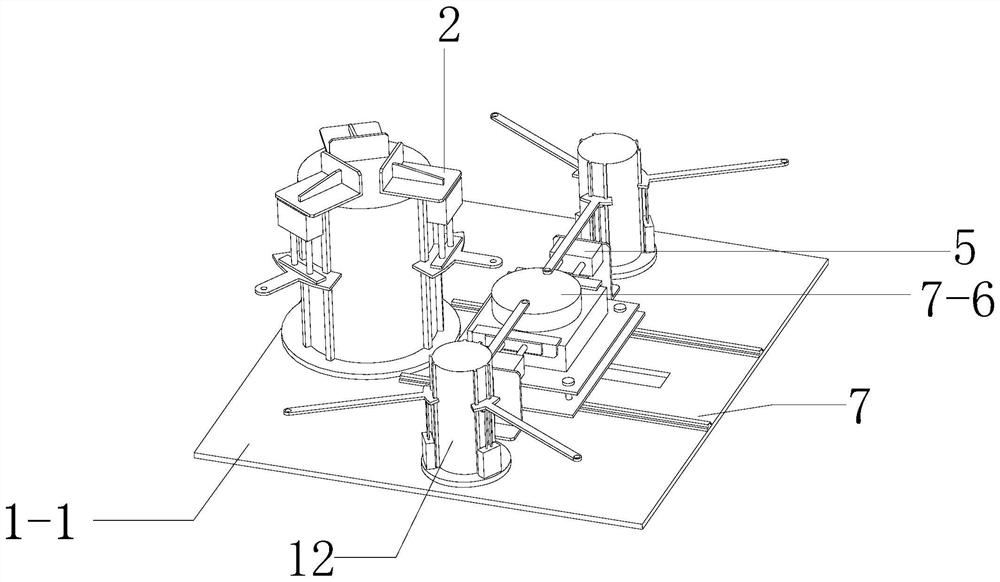

Energy consuming type bolt type connecting method used for concrete precast column and foundation connection

ActiveCN110541429AImprove shear resistanceEnsure safetyFoundation engineeringProtective buildings/sheltersShear capacityPrefabrication

The invention relates to the technical field of connection of an assembly type building in the civil engineering subject, and particularly discloses an energy consuming type bolt type connecting method used for concrete precast column and foundation connection. The method comprises the specific steps of firstly, prefabrication of an upper prefabricated part; secondly, mounting of a lower embeddedpart; thirdly, foundation template bracing and concrete pouring and curing; fourthly, preparation before precast column mounting construction; fifthly, precast column and foundation connection; sixthly, damper connection; and seventhly, pouring and curing of post-cast concrete on a connecting joint. Anti-shear capacity of the bottom of concrete precast columns can be improved, the whole anti-vibration property is improved, the safety of a building is ensured, and the method is suitable for connection of the concrete precast columns of various specifications and a foundation.

Owner:SHAOXING UNIVERSITY +1

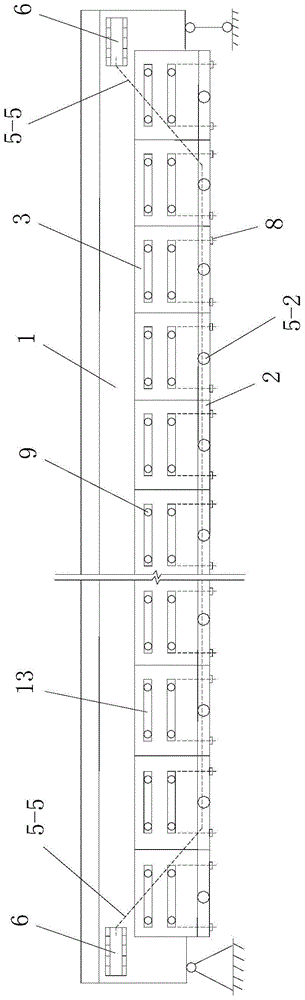

Reinforcement structure and reinforcement method of main girder of reinforced concrete girder bridge

ActiveCN104947603BSimple structureReasonable designBridge erection/assemblyBridge strengtheningReinforced concretePre stress

The invention discloses a reinforced concrete girder bridge girder reinforcing structure and method. The reinforcing structure comprises a reinforcing form board, a concrete structure located in a cavity between the reinforcing form board and a to-be-reinforced girder and a prestress system arranged on the reinforcing form board, wherein the reinforcing form board includes a girder-bottom form board and two girder-side form boards; the prestress system comprises two longitudinal prestress steel strands penetrating the reinforcing form board and a plurality of first transverse prestress steel strands penetrating the girder-bottom form board, four steel anchor boxes are disposed on the to-be-reinforced girder, and the two longitudinal prestress steel strands, two second transverse prestress steel strands and the four steel anchor boxes form the annular prestress system. The reinforcing method includes the steps of firstly, prefabricating the reinforcing form board; secondly, arranging anchor parts; thirdly, hoisting and fixing the reinforcing form board; fourthly, pouring concrete; performing prestress tension. The reinforcing structure and method is reasonable in design, simple in construction, good in reinforcing effect and capable of solve various problems of existing reinforcing methods.

Owner:陕西中项建材科技有限公司

Filter element adhesive for filter element connection

InactiveCN104004474AImprove performanceGood viscosity increasing effectNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyPolyethylene terephthalate

The invention a filter element adhesive for filter element connection, which is prepared from the following components in parts by weight: 90-100 parts of polyvinyl chloride paste resin, 15-35 parts of tackifying resin, 70-100 parts of plasticizer, 3-12 parts of modifier, 50-85 parts of filler and 10-40 parts of assistant. The polyvinyl chloride paste resin prepared by two methods is mixed as an binding agent, and has excellent comprehensive properties; the polyurethane resin is used as the tackifying resin, and has excellent tackifying property, technical properties and storage stability; the polyethylene terephthalate, epoxy resin oil and chlorinated paraffin used as the plasticizer are simultaneously used to obtain the optimal plasticity; the modifier is added to enhance the storage performance; the filler is added to lower the cost and the curing shrinkage; the assistant is added to improve the processibility of the adhesive; and thus, the adhesive has excellent binding effect, and can be used for binding different filter elements.

Owner:WUHU HUATAI

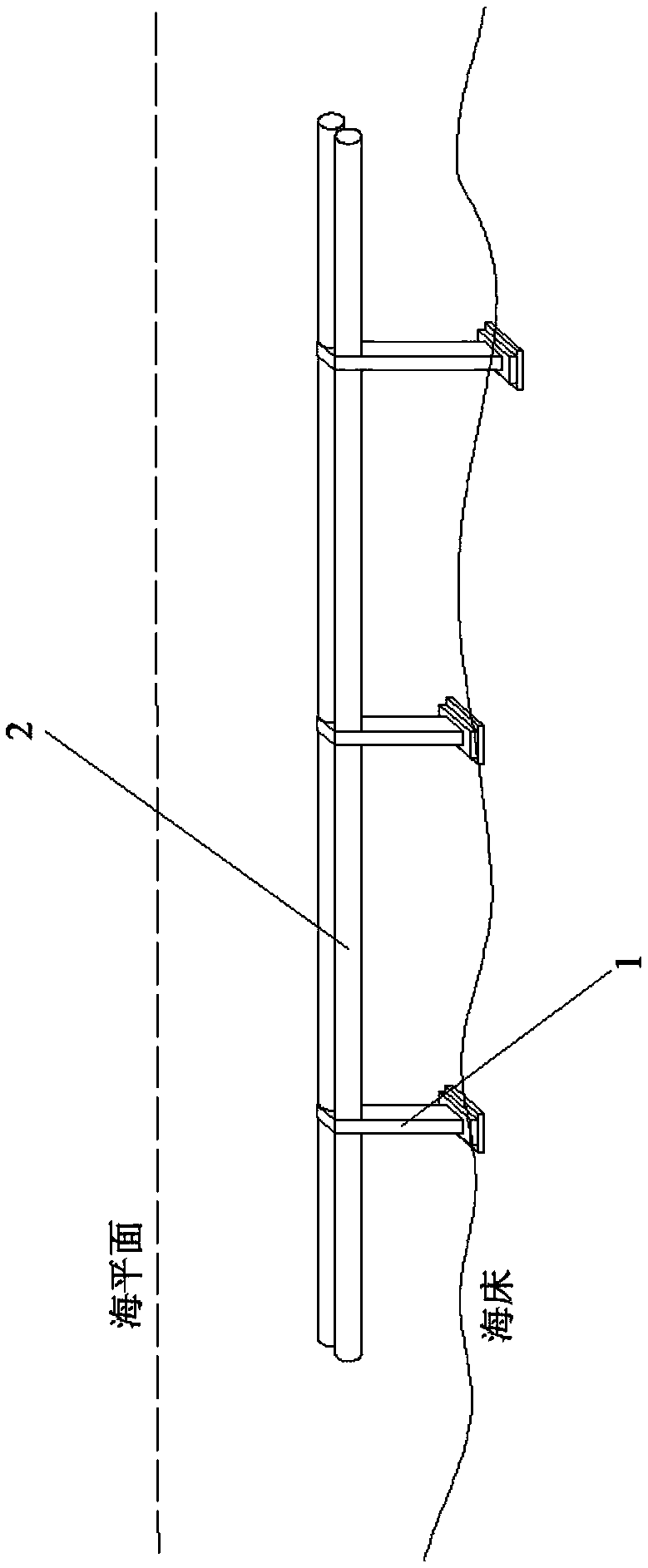

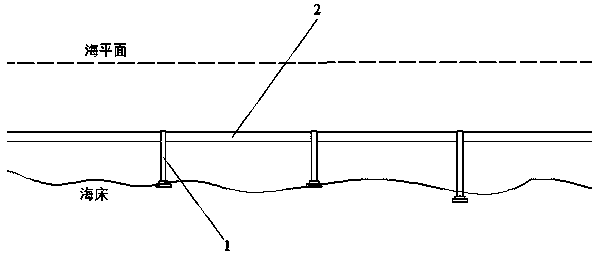

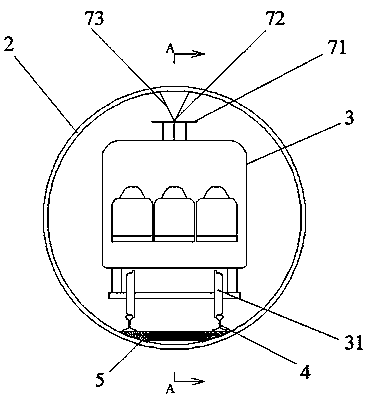

Gravitational equilibrium wheeled vehicle vacuum pipeline traffic system suitable for strait channel

The invention discloses a gravitational equilibrium wheeled vehicle vacuum pipeline traffic system suitable for a strait channel. The system comprises seabed pipe piers, a pipeline and a vehicle. Theincluded angles of wheel sets of wheels of the vehicle range from 80 degrees to 100 degrees. The wheels roll on the pipeline wall and the vehicle can achieve self-stable equilibrium in the pipeline. Power is supplied to the vehicle through a battery or a power grid, and the vehicle is driven by the wheels or a linear motor. Propellers are additionally arranged on a vehicle head, the vehicle is driven by the wheels to travel when the speed is smaller than 200 km / h, and the vehicle is driven through assistance of the propellers when the speed is larger than 200 km / h. An equilibrium gyroscope isarranged to provide stable redundancy for the vehicle, and vehicle operation stability is improved through the tilting train technology. Equilibrium stabilization bars are arranged on the upper sidesor the lower sides, corresponding to the wheels, on the inner wall of the pipeline to prevent the vehicle from being overturned, and rolling grooves are formed, so that the pipeline wall is preventedfrom being abraded. The system has the beneficial effects that the inside of the pipeline is smooth and free of tracks, the pipeline and the vehicle are simple in structure, construction and operationcost is low, and the system is suitable for a cross-sea channel with the low target speed.

Owner:XIJING UNIV

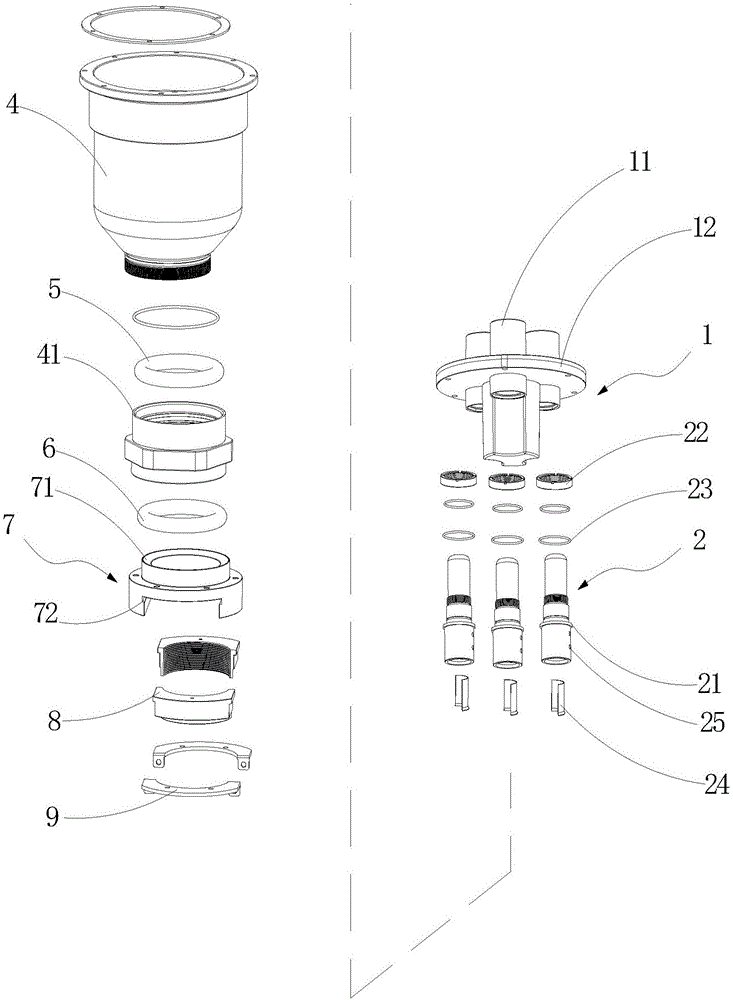

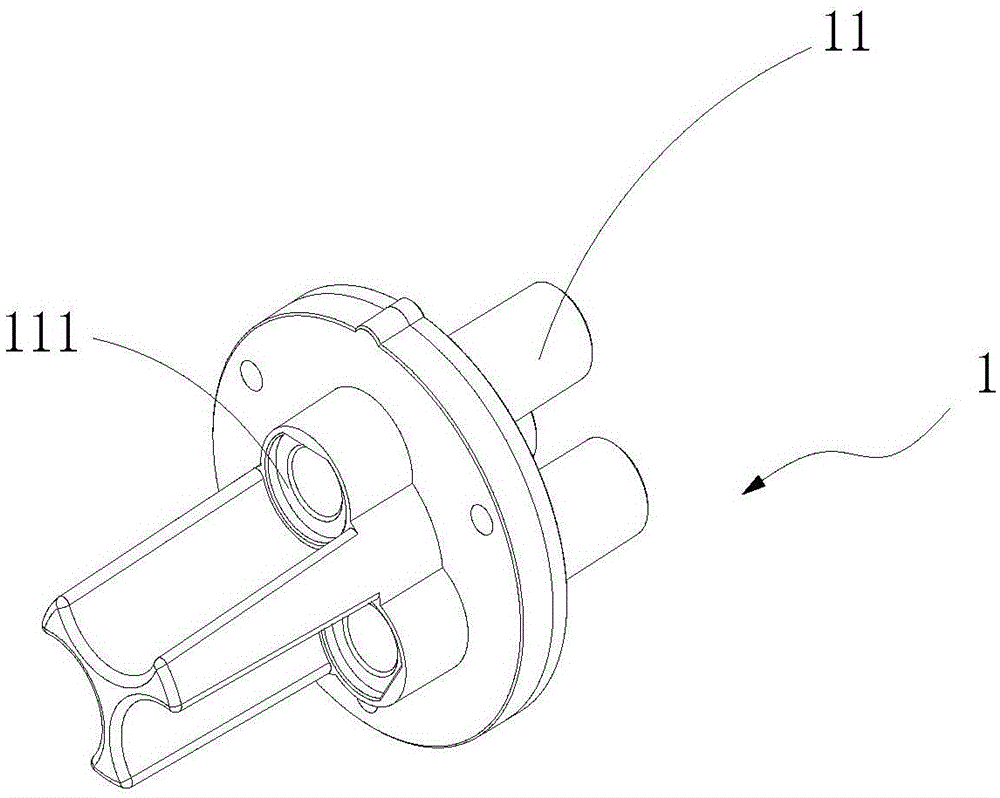

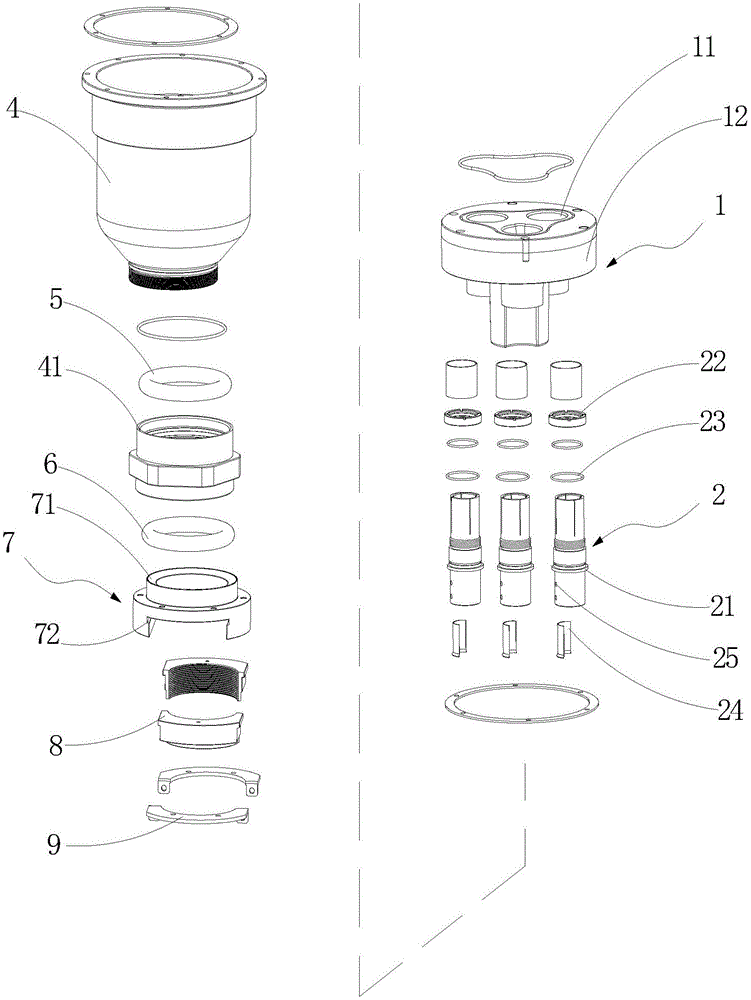

Water-stopping device

InactiveCN101059207AAvoid deformationOpen flexibleCheck valvesPipeline systemsSoft materialsBiomedical engineering

The invention provides a cut-off device, comprising a body, and an elastic element, a brake element, a water retaining pad, a water inlet disc and a washer which are arranged in the body sequentially along the direction from the downstream to the upstream; the water retaining pad is made of soft material; the water retaining pad and the water inlet disc are provided with water inlet holes; furthermore, the water inlet hole of the water retaining pad and the water inlet hole of the water inlet disc are staggered with each other; wherein, the internal wall of the body is provided with a first terrace edge, a second terrace edge, a third terrace edge and a fourth terrace edge which are respectively butted to the elastic element, the water retaining pad, the water inlet disc and the washer; the body and the position corresponding to the second terrace edge are provided with permeable holes which are communicated with the interior of the body; the circumference of the water retaining pad is provided with a labial margin which is warped upwards. As the circumference of the water retaining pad is provided with the labial margin, the elastic pressing of the water retaining pad is more flexible; meanwhile, the water retaining pad is not deformed owning to the increased locking strength of a pipeline.

Owner:黄仲义

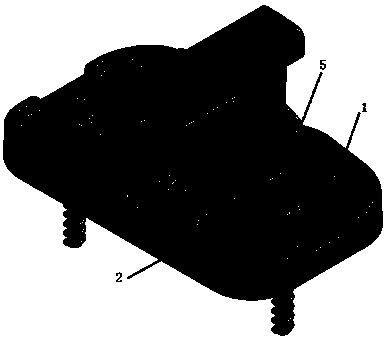

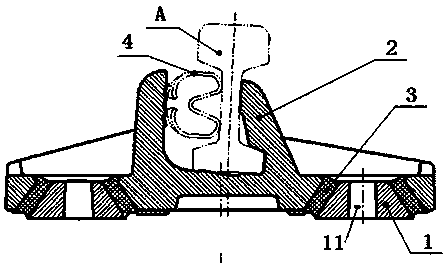

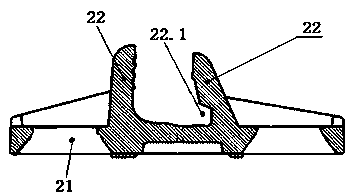

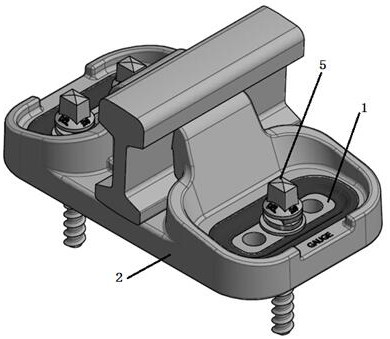

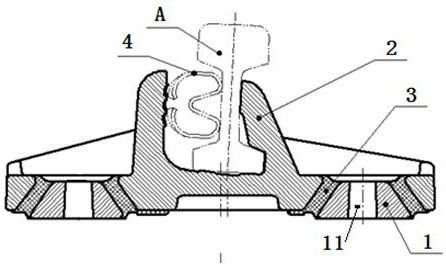

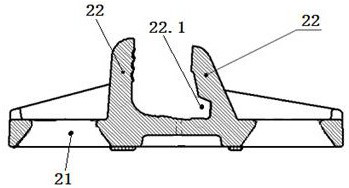

Rail damper with built-in bottom plate and design method thereof

ActiveCN109537375AIncrease lateral stiffnessIncrease stiffnessRailway tracksVulcanizationEngineering

The invention relates to a rail damper with a built-in bottom plate and a design method thereof, the damper comprises a bottom plate, a roof, a rubber layer, and an elastic clasp of a rail pressed together with the roof, the damper is characterized in that the bottom plate is placed in the roof and is in vulcanization connection with the roof through a rubber layer. The vulcanized joint surfaces of the bottom plate and roof are both inclined planes, and the bottom plate is provided with anchoring mounting holes for being fixedly connected with a sleeper. The bottom plate is arranged in the roof, and the installation position of the rail damper is designed in the inner part of the product to reduce the requirement for the installation size of the sleeper, which is suitable for the connection of a small sleeper and a rail damper, thus improving the transverse stiffness of the rail damper. The rigidity of the rail damper can be adjusted, the probability of permanent deformation of the rubber layer can be reduced, the reliability of use of the rail damper is improved, the vulcanization molding is simpler, the requirements of mold, technology and equipment are lower, and the transverserestraint performance of the rail damper is improved. The safe driving performance of small curve radius sections is improved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

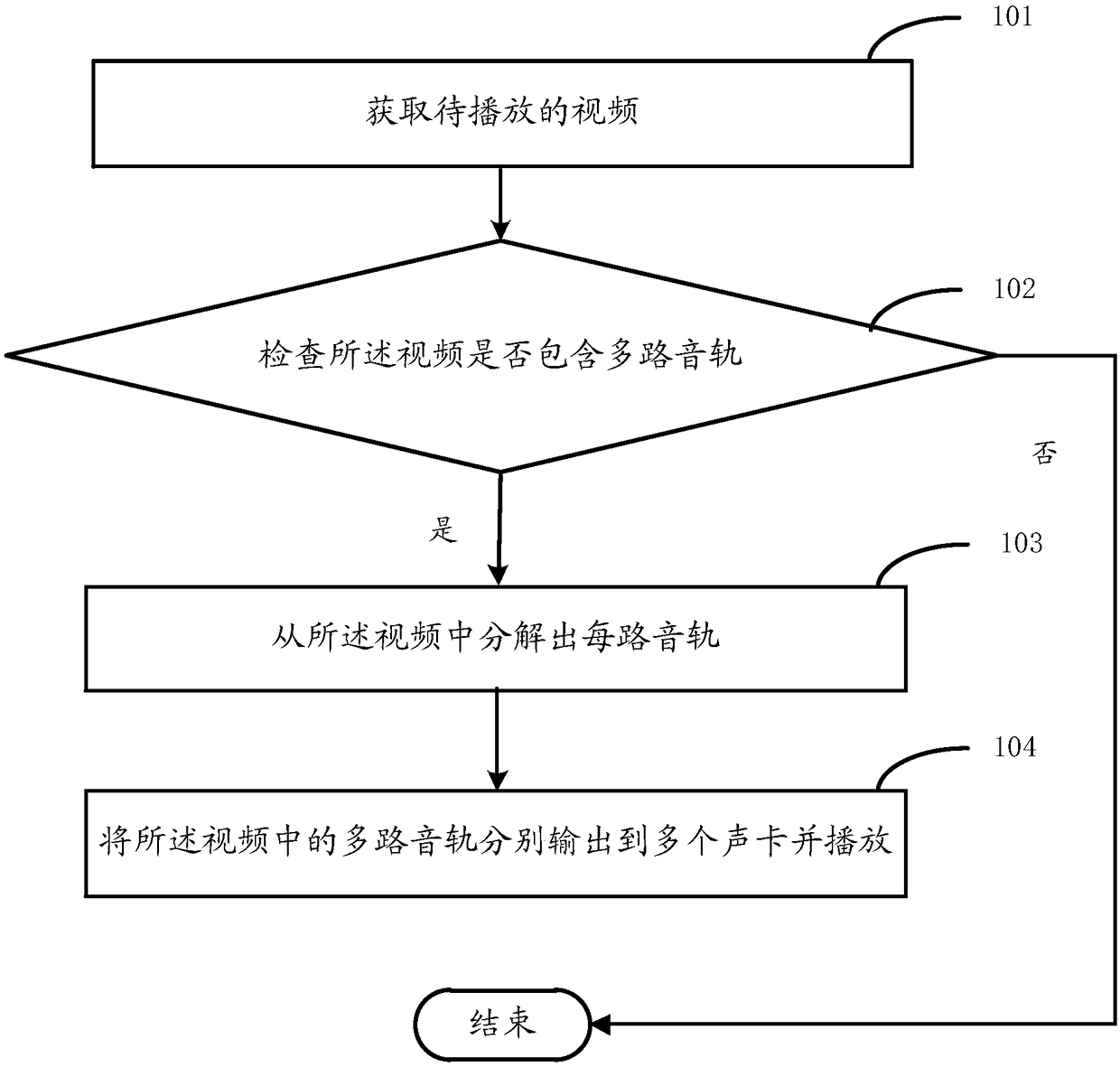

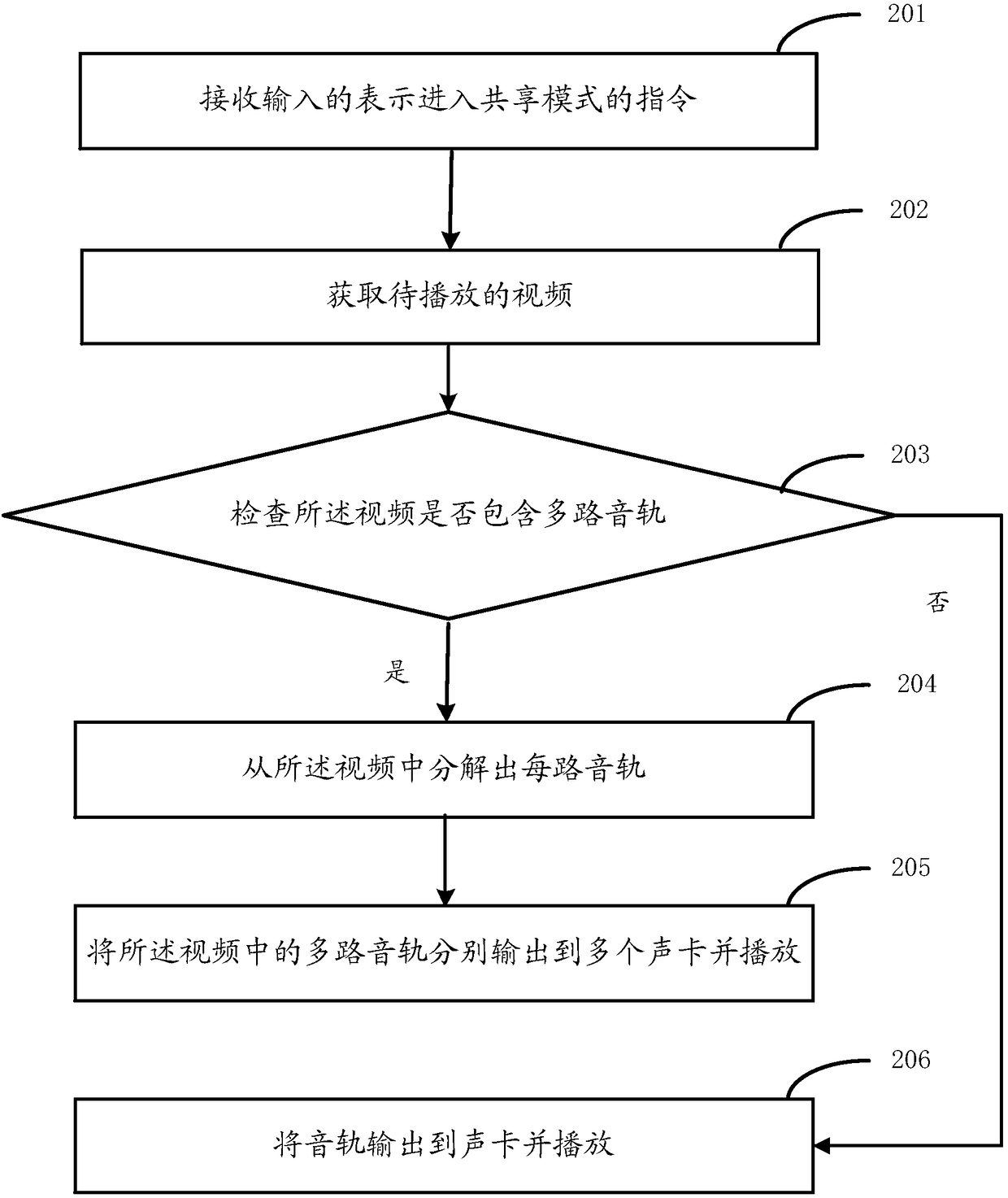

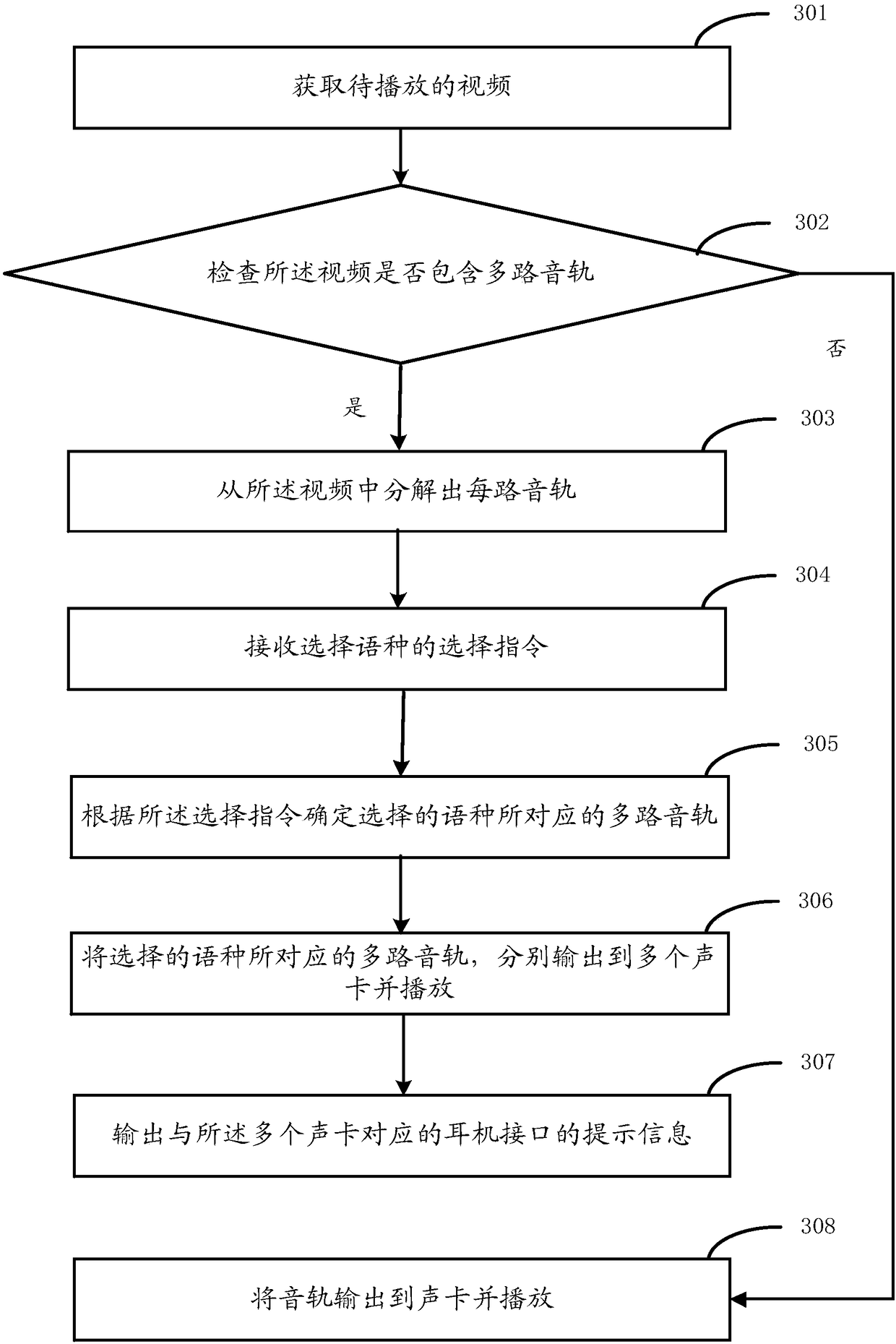

Audio processing method and device

PendingCN108153508ATo achieve separate outputApplicable connectionSound input/outputComputer scienceSound card

The invention discloses an audio processing method and device for achieving independent output of multi-way audio tracks. The method comprises the steps of obtaining videos to be played; examining whether or not the videos contain the multi-way audio tracks; when the videos contain the multi-way audio tracks, each way of audio track is analyzed from the videos; the multi-way audio tracks in the videos are output to multiple sound cards and videos are played, wherein one way of the audio track corresponds to one sound card.

Owner:北京拉近众博科技有限公司

Conductive adhesive, solid conductive adhesive film and preparation method and application thereof

ActiveCN113831876AImprove conductivityLow costPolyureas/polyurethane adhesivesFilm/foil adhesives without carriersPolymer sciencePolymer chemistry

The invention provides a conductive adhesive, a solid conductive adhesive film and a preparation method and application thereof. The conductive adhesive is prepared from the following raw materials in specific parts: thermoplastic resin, thermosetting resin, conductive filler, a conductive accelerant and a curing agent. According to the conductive adhesive, thermoplastic resin is matched with thermosetting resin to serve as a matrix, and specific parts of conductive filler and conductive accelerant are added, so that the conductive adhesive has excellent conductive performance under the condition that the addition amount of the conductive filler is relatively low, and further the conductive adhesive has excellent mechanical performance; and the solid conductive adhesive film prepared from the conductive adhesive also has relatively high bonding strength and aging resistance, and can be applied to connection of devices in a module.

Owner:深圳市南科康达科技有限公司

Optical fiber converting adaptor

PendingCN105759368AReduce connection lossSmall footprintCoupling light guidesBiochemical engineeringButt joint

The invention discloses an optical fiber converting adaptor which comprises an adaptor assembly and an interface assembly.The adaptor assembly comprises an outer shell and a clamping body, wherein the clamping body is in clamping fit with the outer shell, and is located in an inner cavity of the outer shell and used for fixing an SC type non-standard ceramic sleeve and connecting an SC type optical fiber movable connector.The clamping body is provided with a cylindrical groove used for fixing the SC type non-standard ceramic sleeve.The interface assembly comprises a limiting ring and a shell, wherein one end of the limiting ring is arranged on an SC type non-standard ceramic insertion core in the SC type non-standard ceramic sleeve in a sleeving mode, the other end of the limiting ring is embedded in the clamping body to be in butt joint with the end face of the SC type non-standard ceramic sleeve and is arranged on the SC type non-standard ceramic insertion core in a sleeving mode, and the shell is arranged on the SC type non-standard ceramic insertion core in a sleeving mode and connected with the limiting ring.The adaptor assembly is used for being connected with the SC type optical fiber movable connector, the interface assembly can be directly in butt joint with equipment with an FC type interface, use is convenient and flexible, and the overall connection loss of a link can be reduced.The optical fiber converting adaptor is suitable for collecting the SC type optical fiber movable connector and the equipment with an FC type interface.

Owner:河北四方通信设备有限公司

A kind of low-silver copper-based solder and preparation method thereof

ActiveCN103624418BReduce contentReduce dosageWelding/cutting media/materialsSoldering mediaRare earthFiller metal

The invention relates to a low-silver-copper-based brazing filler metal and a preparation method thereof. The low-silver-copper-based brazing filler metal comprises Ag, Cu and P, wherein Sn, Ni and rare earth are further added, the weight percentages of the components are as follows: 1.5%-2.5% of Ag, 5.5%-6.6% of P, 5%-7% of Sn, 1.0-2.5% of Ni, not more than 0.05% of rare earth and the balance of Cu; the preparation method of the low-silver-copper-based brazing filler metal comprises the following steps of preparing Sn to filament Sn, smelting, continuously casting, continuously extruding, forming and cleaning to obtain the brazing filler metal. The brazing filler metal has the advantages of reasonable formulation design, lower brazing filler metal melting temperature, good wettability and mobility, stable quality of a soldered joint and long service life; a BCu80AgP copper-phosphorus brazing filler metal can be replaced, and the production cost of motor brazing is greatly reduced. The preparation method of the brazing filler metal can effectively solve a segregation problem of Sn, a preparation process is optimized, and the quality of the prepared brazing filler metal is remarkably improved.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

Wheel track vehicle submarine vacuum pipeline traffic system suitable for strait channel

InactiveCN108622117AReduce technical difficultyReduce uncertaintyArtificial islandsRailway tunnelsOcean bottomEngineering

The invention provides a wheel track vehicle submarine vacuum pipeline traffic system suitable for a strait channel. The wheel track vehicle submarine vacuum pipeline traffic system comprises submarine pipe piers, a pipeline, a vehicle, vehicle wheels, a track, rail braces, a linear motor, a pantograph, a contact net, a life-support system and a vehicle-mounted power battery. The wheel track vehicle submarine vacuum pipeline traffic system is characterized in that the pipe piers are arranged on the seabed, the pipeline is set up on the pipe piers, a technical scheme similar to high-speed wheelrail vehicles is adopted, track gauge is 700-1000mm, the width / height is 1.5-2m, a passenger cabin is of an air tight structure and is internally provided with the life-support system, the running speed is 100-1000km / h, and an operating exhaust mode is used to form vacuum for the pipeline. A top current collection or bottom current collection mode is adopted when electricity is taken from a powergrid; a vehicle-mounted power accumulator or long stator linear motor mode is adopted when electricity is not taken from the power grid; and a wheel driving / braking or linear motor driving / braking mode is adopted, or the wheel driving / braking and the linear motor driving / braking form a binding mode. The wheel track vehicle submarine vacuum pipeline traffic system has the advantage that the transport construction and operating costs of a strait channel submarine vacuum pipeline is reduced.

Owner:XIJING UNIV

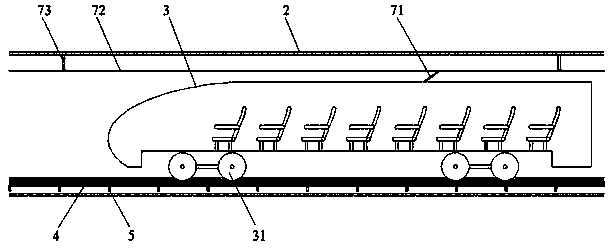

Cable for high-performance electrical vehicle conductive charging system

InactiveCN105957588AHigh elongation at breakGood flexibilityNon-insulated conductorsFlexible cablesWeather resistanceInsulation layer

The invention discloses a cable for a high-performance electrical vehicle conductive charging system. The cable comprises a cable core bunch, and an inside liner, a shielding layer and a sheath layer are arranged at the periphery of the cable core bunch in sequence. The cable core bunch comprises a plurality of conductor cable bunches which are annularly twisted in the inside liner, and a control signal cable bunch. Each conductor cable bunch comprises a conductor and a first insulation layer coating at the periphery of the conductor. The control signal core bunch comprises a control signal conductor, and a second insulation layer, a shielding layer and an inside sheath layer which coat at the periphery of the control signal conductor from the inside to the outside in sequence. The cable has the advantages of high softness, relatively high weather resistance and relatively high abrasive resistance and tear resistance.

Owner:GOLD CUP ELECTRIC APP HENGYANG CABLES

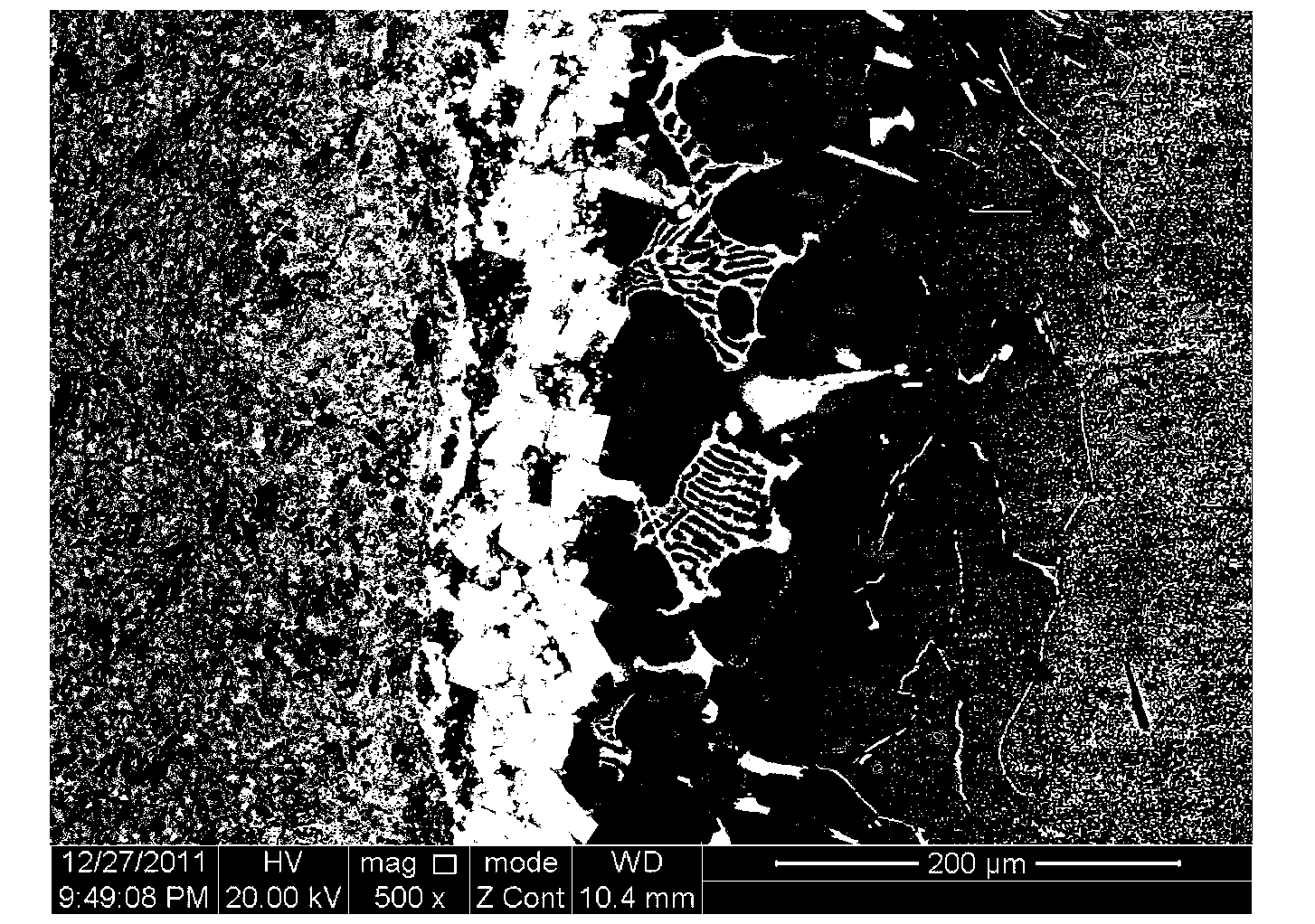

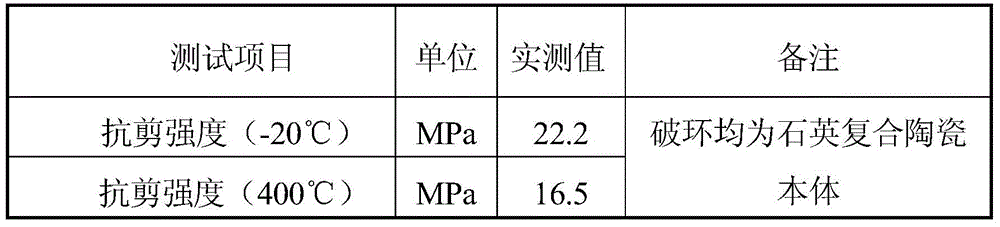

Liquid Phase Diffusion Bonding Method of Quartz Composite Ceramics and Iron-Nickel Alloy

ActiveCN104874909BApplicable connectionImprove connection strengthWelding/soldering/cutting articlesNon-electric welding apparatusCeramic compositeSurface cleaning

The invention discloses a liquid-phase diffusion bonding method for quartz composite ceramic and an iron-nickel alloy. The liquid-phase diffusion bonding method comprises the following steps: surface cleaning is performed: the bonding surface of the iron-nickel alloy is cleaned with acetone, and nickel plating is performed on the bonding surface of the quartz composite ceramic with a chemical nickel plating process; an interlayer alloy is prepared: foil with a certain thickness is prepared from the interlayer alloy containing trace Ni, Ag and Cu elements; joint assembling clearance is designed; liquid-phase diffusion bonding is performed: the quartz composite ceramic material, the interlayer alloy and the iron-nickel alloy are assembled by a tool and placed into a vacuum furnace, nitrogen is introduced for protection, heat is preserved for 15-60 min at the temperature of 380-550 DEG C, and the cooling with the furnace is performed. The bonding joint of the quartz composite ceramic and the iron-nickel alloy is stable, the bonding strength is high, high-temperature resistance is realized, and the liquid-phase diffusion bonding method is particularly applicable to bonding of the quartz composite ceramic material and the iron-nickel alloy material which have large sizes.

Owner:湖北三江航天江北机械工程有限公司

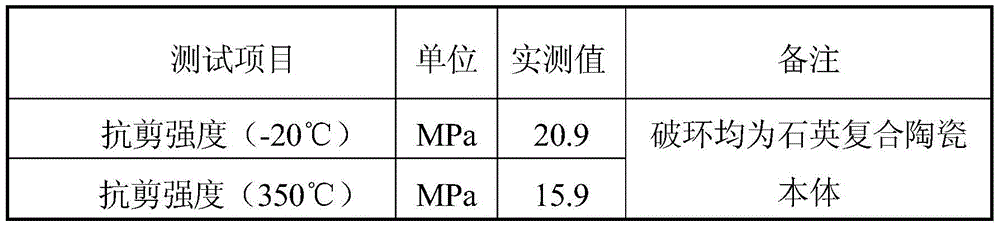

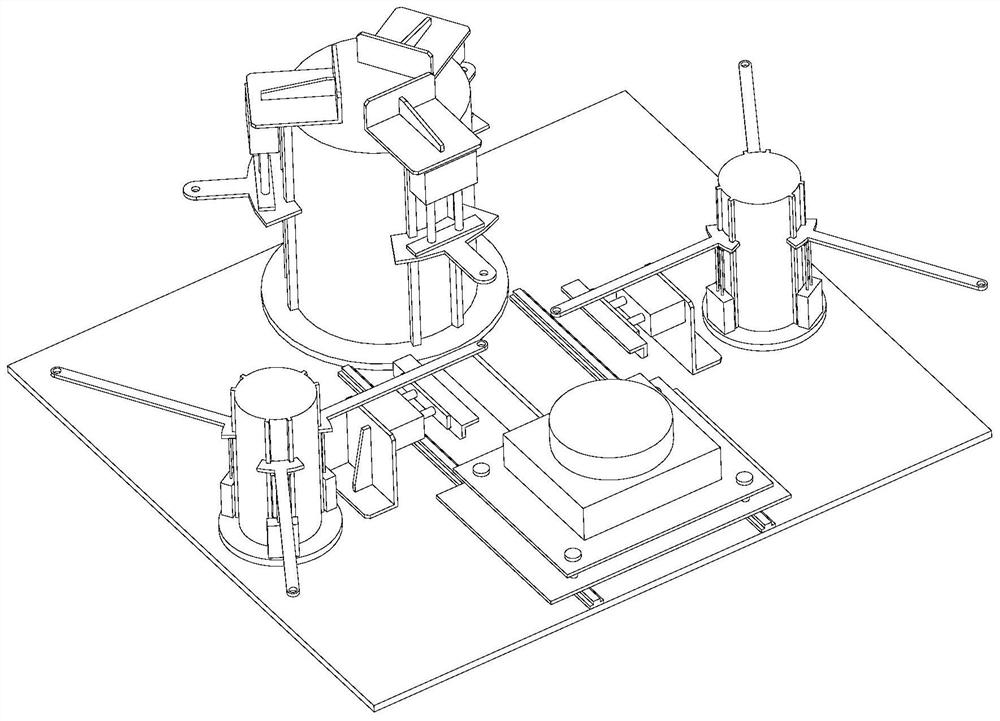

Shock-absorbing rear-anchored type fabricated column-foundation connection device

InactiveCN110565798AImprove shear resistanceEnsure safetyFoundation engineeringProtective buildings/sheltersAgricultural engineeringRebar

The invention relates to the technical field of connection of fabricated buildings in civil engineering, and particularly discloses a shock-absorbing rear-anchored type fabricated column-foundation connection device. The shock-absorbing rear-anchored type fabricated column-foundation connection device comprises an upper prefabricated part, a lower pre-buried part arranged in a foundation, and post-cast concrete; the upper prefabricated part comprises a prefabricated column and an upper positioning plate, the lower pre-buried part comprises foundation steel bars, a lower positioning plate and anchor bolts, and the upper positioning plate and the lower positioning plate are connected through the anchor bolts; and dampers are connected between the middles of the four sides of the bottom faceof the prefabricated column and the side face of the foundation. According to the shock-absorbing rear-anchored type fabricated column-foundation connection device, the anti-shear ability of the bottom of the concrete prefabricated column is improved, the overall anti-seismic performance is also improved, the safety of a building is ensured, and the shock-absorbing rear-anchored type fabricated column-foundation connection device is suitable for connection of concrete prefabricated columns and foundations of various specifications.

Owner:浙江中清大建筑工业有限公司 +1

High-voltage cable connector

InactiveCN105098468AApplicable connectionImprove stabilityCouplings bases/casesPower flowHigh pressure

The invention discloses a high-voltage cable connector, comprising a plug connector and a socket connector which are mutually connected in a plugged way. The high-voltage cable connector is applicable to connecting high-voltage cables with large diameter and high current and further locking cables with locking components, thus ensuring good stability.

Owner:GUANGZHOU RMEECO WATERPROOF & APPLIANCES CO LTD

Polyethylene water supply electric smelting pipe

InactiveCN108061215AFirmly connectedApplicable connectionPipe-jointsPipe connection arrangementsWear resistantTube diameter

The invention discloses a polyethylene water supply electric smelting pipe. According to the technical scheme, the two ends of a pipe body are connected with a first end head and a second end head correspondingly, the first end head and the second end head are square heads, a round joint is connected on the first end head, a square joint is connected on the second end head, a contraction step is arranged on the inner wall of the round joint, a bonding ring is further arranged at the tail end of the round joint, a plurality of vibration damping pieces are arranged on the outer wall of each of the first end head and the second end head, wherein each vibration damping piece is of a multi-layer structure, and sequentially comprises a wear-resistant plastic layer, an elastic rubber layer and ametal gasket layer from outside to inside. According to the polyethylene water supply electric smelting pipe, one end head is arranged at each of the two ends of the pipe body, the round head and thesquare head are arranged on the end heads correspondingly, so that the pipe is suitable for being connected with pipelines with different shapes, one contraction step is further arranged on the innerwall of the round head and can be used for being connected with pipelines with different pipe diameters; and the polyethylene water supply electric melting pipe has better connectivity, and is suitable for being connected with pipes with different pipe diameters.

Owner:江苏艺源管业有限公司

Energy-dissipating bolted connection method for the connection between prefabricated concrete columns and foundations

ActiveCN110541429BImprove shear resistanceEnsure safetyFoundation engineeringProtective buildings/sheltersArchitectural engineeringSeismic resistance

Owner:SHAOXING UNIVERSITY +1

Installation method for fuel cell air compressor under complex distribution of bolt holes

ActiveCN112846740AApplicable connectionShorten the timeMetal working apparatusFuel cellsStructural engineering

The invention discloses an installation method for a fuel cell air compressor under complex distribution of bolt holes. The method particularly provides three ways. According to the first and second ways, when nuts are not considered, that is, when bolt-workpiece bolt holes are installed, no problem exists, that is, the installation method is suitable for any complex bolt hole distribution. The third way is a universal control method for installation of the bolt, the workpiece and the nut and installation of the bolt and the workpiece. The installation method for the fuel cell air compressor under complex distribution of the bolt holes, the bolt installation efficiency of workpieces is improved.

Owner:擎能动力科技(苏州)有限公司

Bottom plate built-in rail damper and its design method

ActiveCN109537375BReduce installation size requirementsApplicable connectionRailway tracksVulcanizationClassical mechanics

Bottom plate built-in rail shock absorber and its design method, including bottom plate, top plate, rubber layer and elastic clips that cooperate with the top plate to press the steel rail, characterized in that the bottom plate is placed in the top plate, and vulcanized by the rubber layer and the top plate Connection, the vulcanized connection surfaces of the bottom plate and the top plate are sloped, and the bottom plate is provided with anchor holes for fixing with sleepers. In the present invention, the bottom plate is arranged in the top plate, that is, the installation position of the track damper is designed inside the product, and the requirement for the installation size of the sleeper is reduced. Lateral rigidity, realizing the adjustable stiffness of the rail shock absorber, reducing the probability of permanent deformation of the rubber layer, improving the reliability of the rail shock absorber, simpler vulcanization molding, lower requirements for molds, processes, and equipment, and improving The lateral restraint performance of the rail shock absorber improves the safe driving performance of the road section with small curve radius.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com