Long-time creep fixture

A fixture and creep technology, applied in the field of permanent creep fixtures, can solve the problems of aggravating the uneven force of the sample, deviation from the deformation of the sample, and increasing the test cost, so as to avoid the failure of test data, accurate test results, The effect of reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is described in further detail below with reference to the accompanying drawings and embodiments:

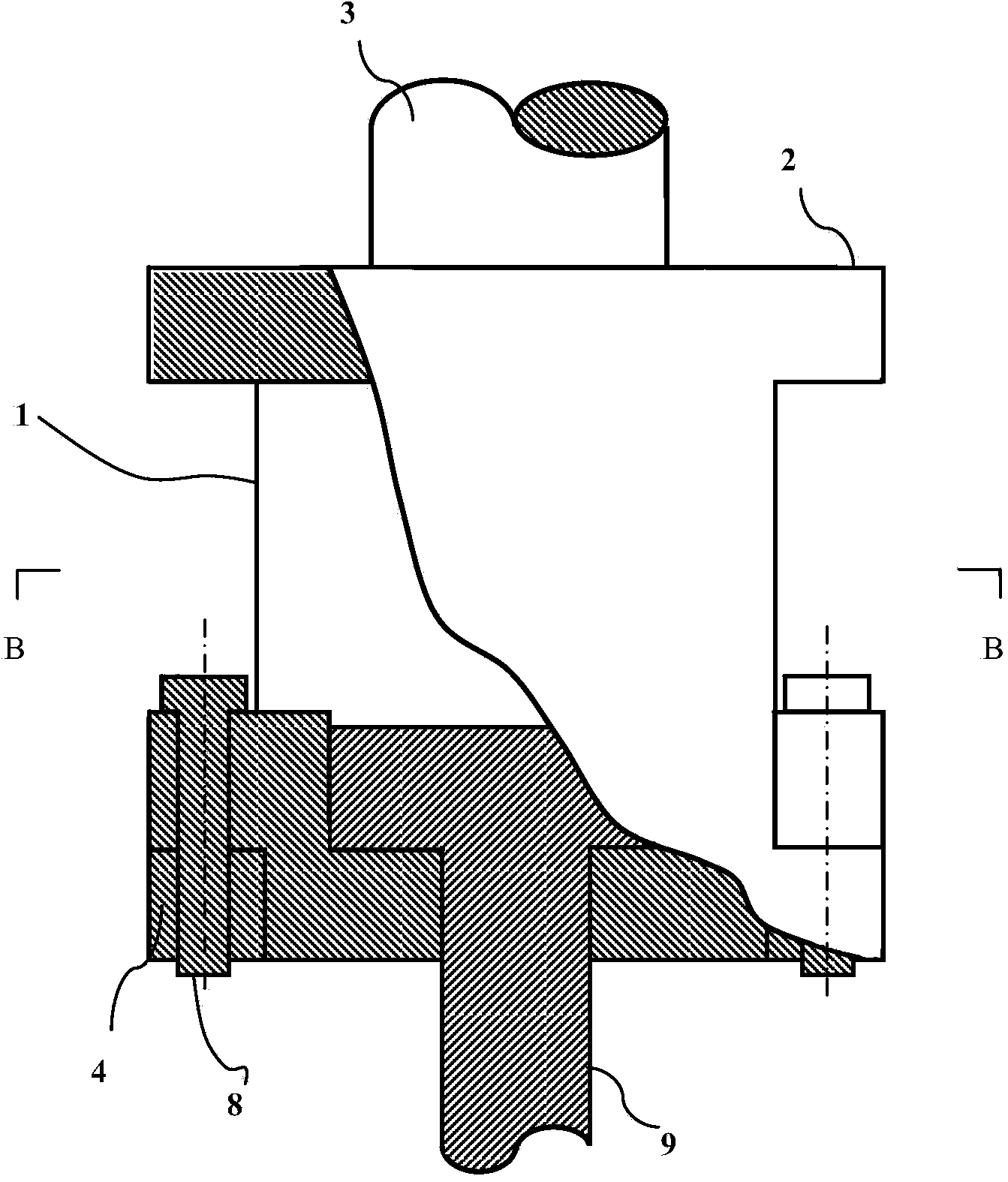

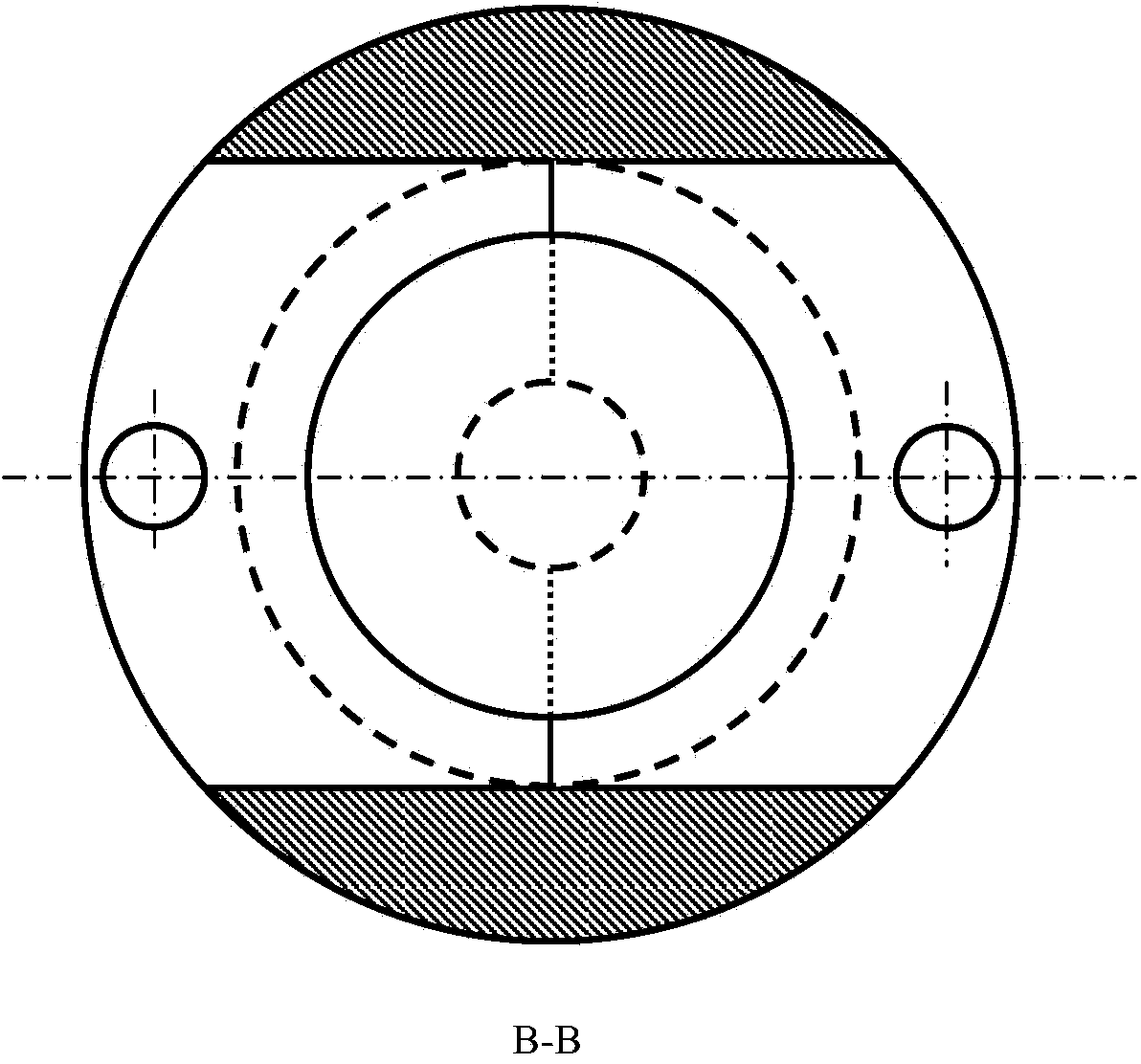

[0021] Such as Figure 1~4 As shown, the fixture includes:

[0022] A cylindrical jig body used to connect with the testing machine and bear the tensile load from the testing machine. The jig body has a column 1 whose outer surface is a circular arc segment on both sides of the radial direction, and the inner surface of the column 1 is vertical. In the radial plane, the upper end of the column 1 is integrated with the upper cover 2 of the fixture body. The upper part of the upper cover 2 is a solid cylinder 3 connected to the testing machine, and the lower end of the column 1 is connected to the ring body 4 at the bottom of the fixture body. Connected into one body, the inner edge surface of the torus 4 is tangent to the inner surface of the column 1;

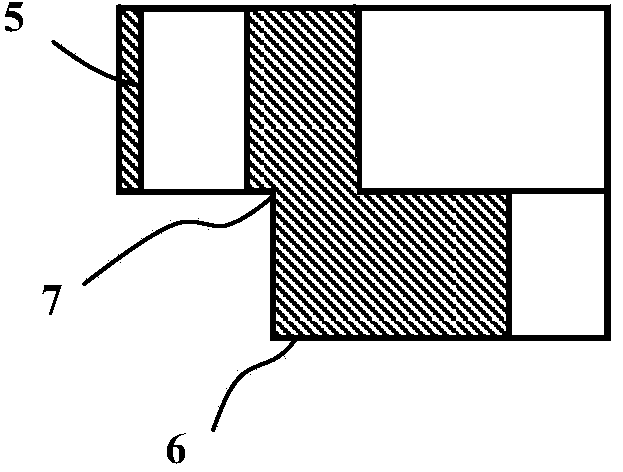

[0023] Two arc-shaped seat covers with the same structure, the seat co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com