Fixing part used for fixing water heater pipeline

A technology for fixing parts and water heaters, applied in the directions of fluid heaters, pipes/pipe joints/pipe fittings, passing elements, etc., can solve the problems of high rigidity, poor sealing, and short service life at the joints between the fixing parts and pipes. Strengthen the overall sealing effect, reduce the probability of water leakage, and the overall structure is beautiful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

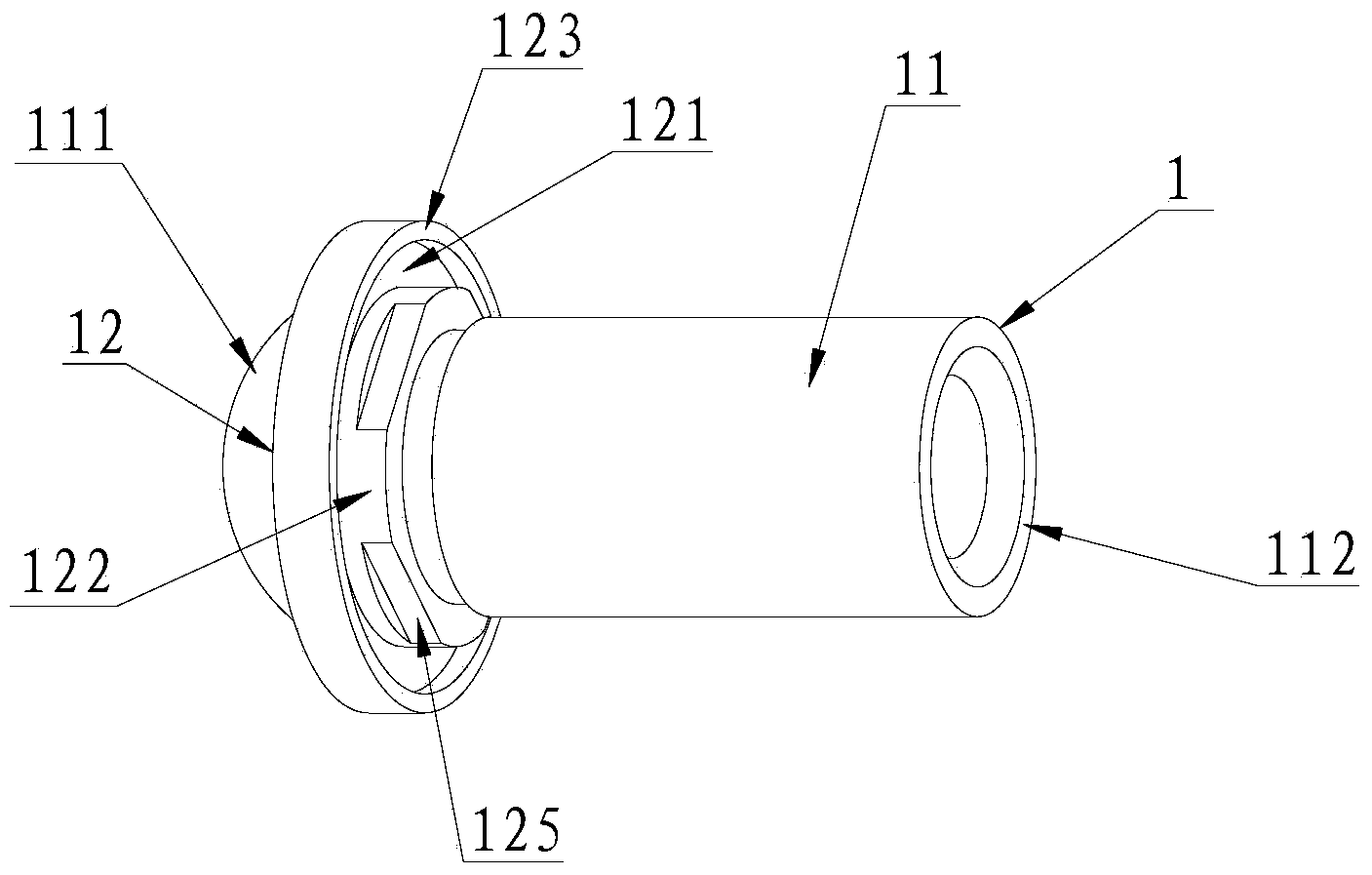

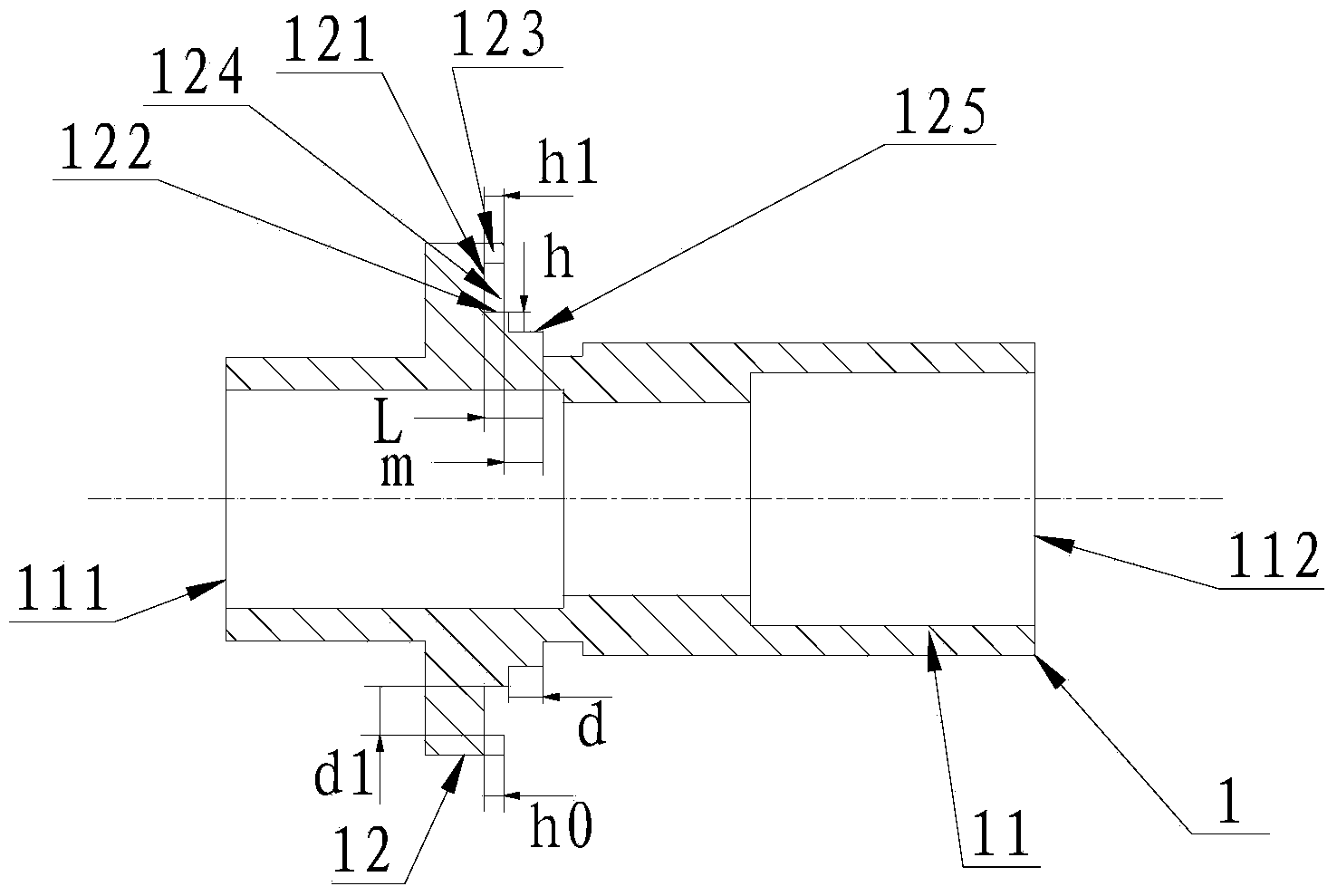

[0034] A fixture for fixing water heater pipes, see figure 1 , figure 2 As shown, the fixing part 1 includes a body 11 and a boss 12 .

[0035] The body 11 is a hollow structure, and pipes and the like pass through the hollow part for fixing.

[0036] The body 11 includes a front end 111 and an end 112, the boss 12 is arranged on the outer wall of the front end 111, the boss 12 includes an L-shaped side formed by a first side 121 and a second side 122, the The top of the first side 121 is provided with a protrusion 123 towards the end 112, and a first groove 124 is formed between the protrusion 123 and the first side 121 and the second side 122 of the boss; The depth h1 of a groove 124 is 30mm, and the width d1 is 40mm; the length of the protrusion 123 is 30mm, and the width is 20mm, and components such as a sealing ring can be arranged in the first groove 124 for sealing, and the sealing effect is good.

[0037] The circumferential direction of the second side 122 of the ...

Embodiment 2

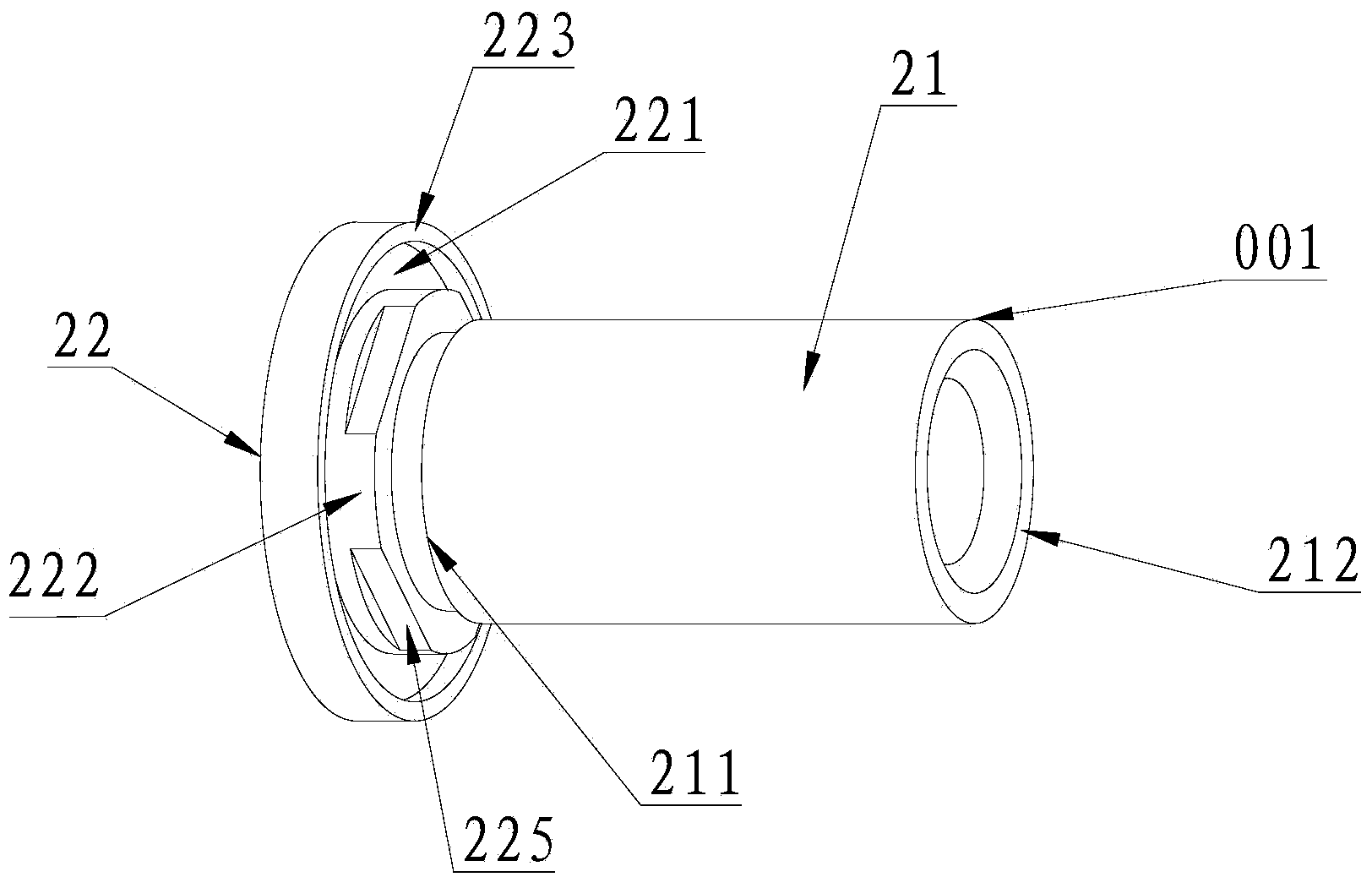

[0040] A fixture for fixing water heater pipes, see image 3 , Figure 4 As shown, the fixing member 001 includes a body 21 and a boss 22 .

[0041] The body 21 is a hollow structure, through which pipes and the like are fixed.

[0042] The body 21 includes a front end 211 and an end 212, the boss 22 is arranged on the outer wall of the front end 211, the boss 22 includes an L-shaped side formed by a first side 221 and a second side 222, the The top of the first side 221 is provided with a protrusion 223 towards the end 212, and a first groove 224 is formed between the protrusion 223, the first side 221 and the second side 222; The depth h1 is 30mm, and the width d1 is 40mm; the length of the protrusion 223 is 30mm, and the width is 20mm, and components such as a sealing ring can be arranged in the first groove 224 for sealing, and the sealing effect is good.

[0043] The second side 222 of the boss 22 is milled with a number of mating surfaces 225 greater than or equal to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com