Exhausting type water outlet pipe for engine

A water outlet and engine technology, applied in engine components, machines/engines, engine cooling, etc., can solve the problems of high water leakage, waste of coolant, waste of fuel, etc., to reduce the probability of water leakage, simple cooling circuit, reduce development effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

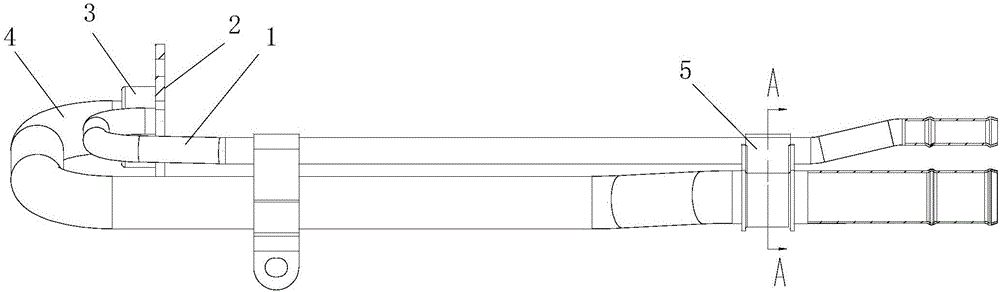

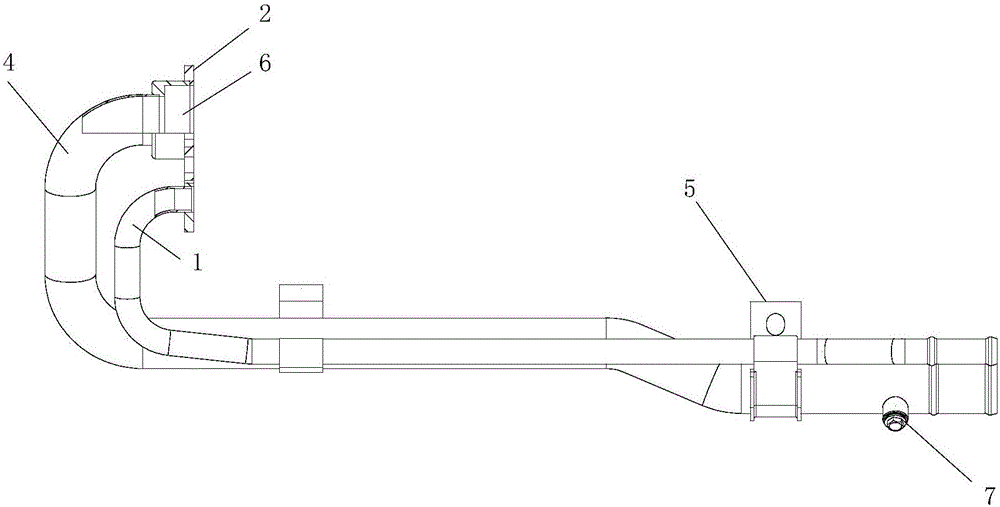

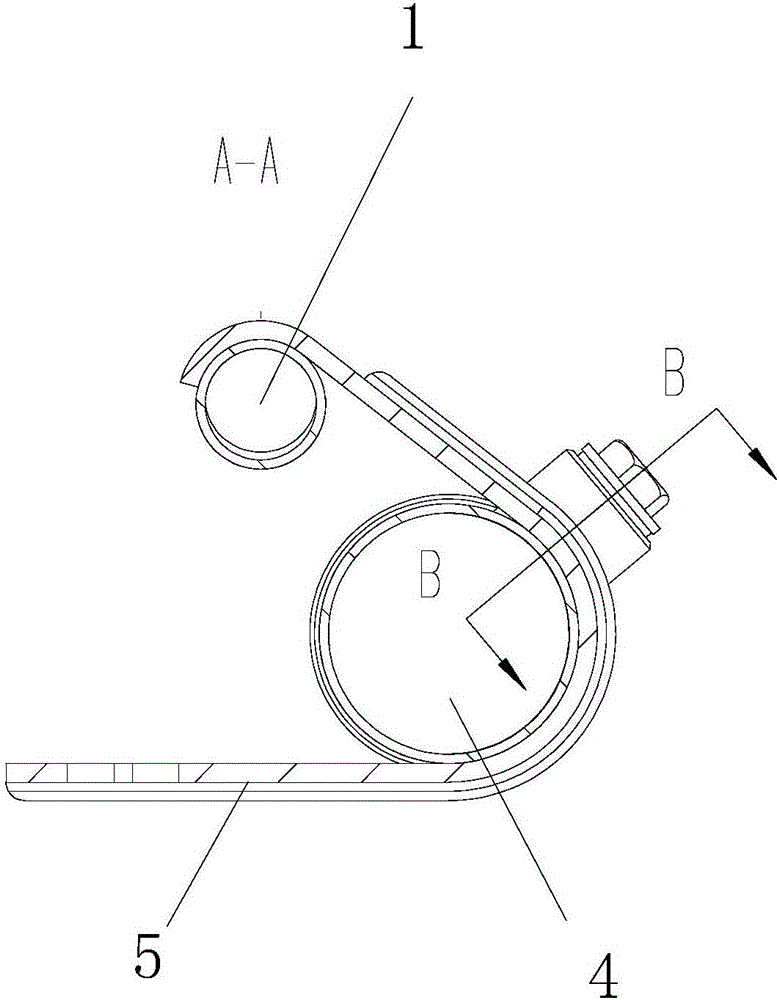

[0019] figure 1 It is a structural schematic diagram of the present invention. As shown in the figure, the ventable engine water outlet pipe of this embodiment includes a large circulation pipe and 4 small circulation pipes 1 fixed to each other; the pipe wall of the large circulation pipe 4 is provided with an exhaust hole, and the exhaust pipe The air hole is closed by the exhaust screw 7, and the large circulation pipe 4 and the small circulation pipe 1 are fixed and integrated with each other, which reduces the development of special parts for the cooling system, makes the cooling circuit simpler, lowers the cost, and reduces the chance of water leakage in the cooling system. , the large circulation pipe 4 is provided with a vent hole and is closed by the vent screw 7, because the cooling system is easy to accumulate gas during the working process, and the outlet pipe part is at the highest point of the engine cooling system, the gas is easy to accumulate near the vent scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com