Combined high-temperature and durable creeping clamp

A combination and fixture technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of increasing the cost of testing, and achieve the effects of reducing test costs, avoiding replacement, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

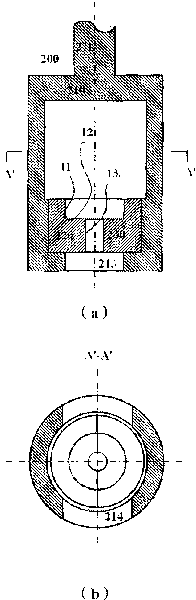

Embodiment 1

[0019] First, refer to figure 2 (a) and figure 2 (b). Such as figure 2 (a) and figure 2 As shown in (b), the combined permanent creep clamp 200 includes a clamp body 210 and a pair of force transmission members 220 and 230 . The clamp body 210 is used to connect with a durability or creep testing machine and carry the tensile load from the testing machine. The clamp main body includes a connecting rod 211 directly connected to the testing machine and a frame member integrated with the connecting rod 211, in which a cavity 212 for accommodating the force transmission members 220 and 230 is formed and is used for receiving and The through hole 213 at the end of the sample is taken out. The cavity 212 has a side opening 214 for receiving and taking out the force transmission members 220 and 230 , and the opening 214 has a size corresponding to or slightly larger than the outer contour size of the force transmission members 220 and 230 . At the bottom of the cavity 212, ...

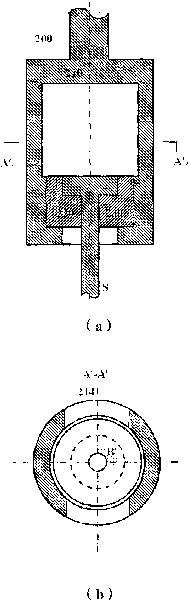

Embodiment 2

[0024] Below, refer to Figure 4 Another structure of the combined permanent creep clamp according to the present invention is described. The difference between this structure and the above structure is that the groove of the cavity of the clamp body 410 is designed to present a certain angle with the loading direction, and the range of the angle is 40° to 90°, preferably 45° to 80°, more preferably 50-70°. Corresponding to this angle, the bottom surfaces of the grooves of the force transmission members 420 and 430 can also be designed to present a certain angle with the loading direction, and the angle ranges from 40° to 90°, preferably from 45° to 80°, more preferably from 50° to 70°. The bottom surfaces of the grooves of the force transmission members 420 and 430 are preferably parallel to the bottom surfaces of the grooves of the cavity of the jig body 410 . In this example, if Figure 4 As shown, the end of the sample P' has a slope that matches the bottom of the groo...

example 1

[0028] The shoulder at the end of the sample is a cylinder with a diameter of 12 mm and a height of 6 mm, and the middle section is a cylinder with a diameter of 5 mm and a height of 32 mm. The surface 11 of the force transmission member is 6 mm high, and the surface 13 is 6 mm high. Two identical force transmission members are combined to form a cylinder with an outer diameter of 14mm and a height of 12mm. The inside of the cylinder includes a hollow portion with a diameter of 12 mm and a height of 6 mm and a hollow portion of 12 mm in diameter and a height of 6 mm in a concentric manner. The jig main body is a cylinder with an outer diameter of 25 mm, the height of the bottom of the cylinder is 6 mm, and the diameter of the through hole 213 is 5 mm. The clamp body and the force transmission member are manufactured from DZ125 alloy by known casting and machining methods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com