Wheel track vehicle submarine vacuum pipeline traffic system suitable for strait channel

A transportation system and vacuum pipeline technology, applied in tunnel systems, vehicle components, electric braking systems, etc., can solve problems such as high cost and difficult construction, reduce uncertainty, reduce construction and operating costs, and reduce technology Effects of Difficulty and Uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

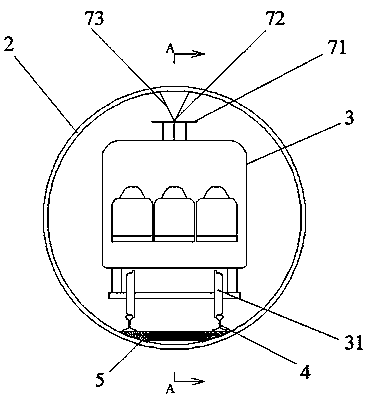

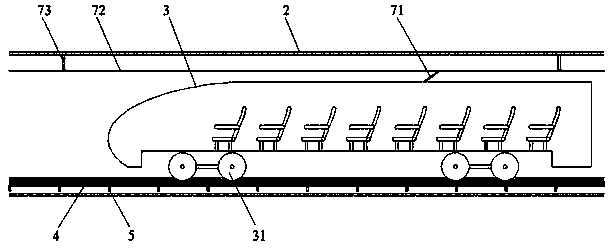

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings.

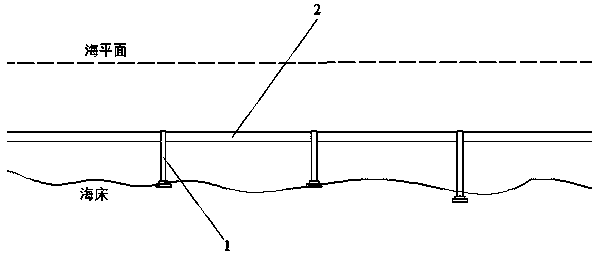

[0042] Such as figure 1 , figure 2 , image 3 As shown, the applicable conditions and scope of the wheel-rail vehicle submarine vacuum pipeline transportation system across the strait and the bay are:

[0043] 1) There are sea areas with a continuous length of more than 1km and a depth greater than 30m, but the maximum depth is less than 1000m. Because when the water depth is less than 30m, the underwater wave force is significant, so it is not suitable for the construction of vacuum pipelines, and cross-sea bridges or immersed tube tunnels will be cheaper; when the depth is large, such as greater than 1000m, the water pressure is very high, plus In the vacuum environment with negative pressure inside the pipeline, the external pressure on the pipe wall will be very large, and the economy of the submarine vacuum pipeline scheme will be reduced.

[0044] 2) The w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com