Liquid Phase Diffusion Bonding Method of Quartz Composite Ceramics and Iron-Nickel Alloy

A composite ceramic, iron-nickel alloy technology, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the problems of low connection efficiency, complex structure, decreased joint strength, etc., to achieve stable and reliable quality and environmental protection. Strong adaptability and the effect of reducing the connection temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

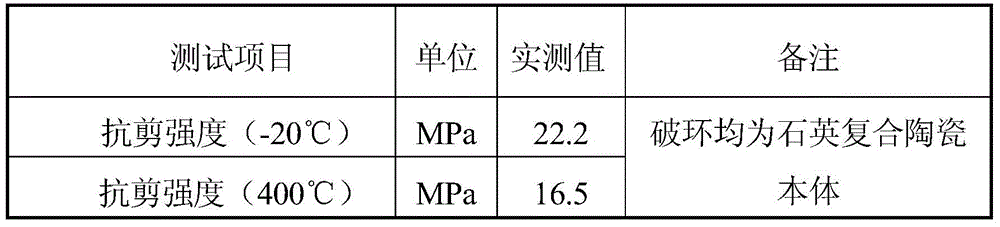

Embodiment 1

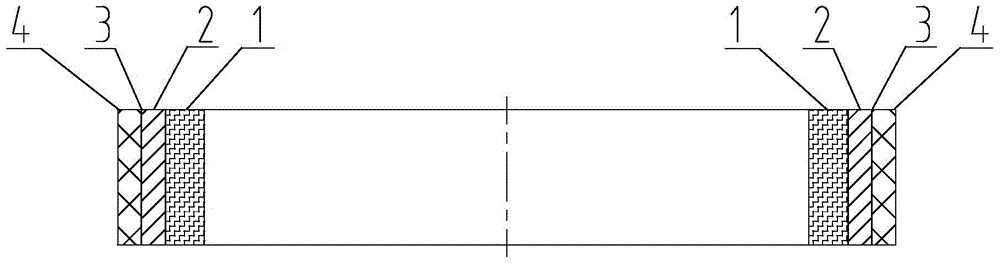

[0026] The liquid phase diffusion connection method of the quartz composite ceramic ring 4 and the iron-nickel alloy ring 2 selected in this embodiment 1 comprises the following steps:

[0027] 1) Surface cleaning: Use acetone to clean the connection surface of the iron-nickel alloy; use the electroless nickel plating process to nickel-plate the connection surface of the quartz composite ceramic. The electroless nickel plating process includes degreasing, roughening, sensitization, activation, and reduction And six steps of plating;

[0028] 2) Intermediate layer alloy foil 3: Au-Ge intermediate layer alloy ring 3 prepared with trace amounts of Ni, Ag, and Cu elements has a thickness of d / 2, wherein the content of Au is 82%, the content of Ge is 15%, the content of Ni is 1.5%, and the content of Ag Content 0.5%, Cu content 1%, d is the assembly gap;

[0029] 3) Joint assembly clearance design: according to the formula L 1 +α 1 ·L 1 (t 2 -t 1 ) = L 2 +α 2 ·L 2 (t 2 -t...

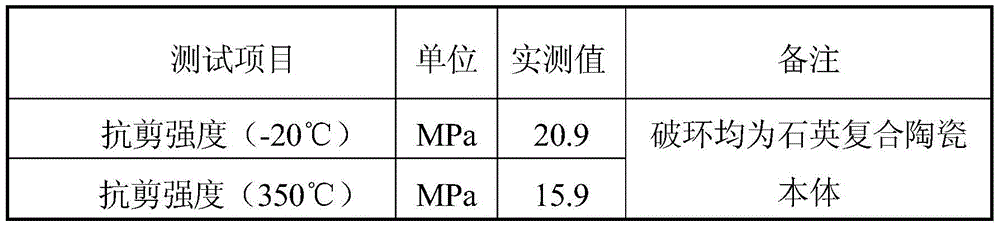

Embodiment 2

[0034] The liquid phase diffusion connection method of the quartz composite ceramic ring 4 and the iron-nickel alloy ring 2 selected in this embodiment 2 comprises the following steps:

[0035] 1) Surface cleaning: Use acetone to clean the connection surface of the iron-nickel alloy; use the electroless nickel plating process to nickel-plate the connection surface of the quartz composite ceramic. The electroless nickel plating process includes degreasing, roughening, sensitization, activation, and reduction And six steps of plating;

[0036] 2) Intermediate layer alloy foil 3: Au-Ge intermediate layer alloy ring 3 prepared with trace amounts of Ni, Ag, and Cu elements has a thickness of d / 2, wherein the content of Au is 75%, the content of Ge is 22%, the content of Ni is 1.5%, and the content of Ag Content 1%, Cu content 0.5%, d is the assembly gap;

[0037] 3) Joint assembly clearance design: according to the formula L 1 +α 1 · L 1 (t 2 -t 1 ) = L 2 +α 2 · L 2 (t 2 ...

Embodiment 3

[0042] The liquid phase diffusion connection method of the quartz composite ceramic ring 4 and the iron-nickel alloy ring 2 selected in this embodiment 3 comprises the following steps:

[0043] 1) Surface cleaning: Use acetone to clean the connection surface of the iron-nickel alloy; use the electroless nickel plating process to nickel-plate the connection surface of the quartz composite ceramic. The electroless nickel plating process includes degreasing, roughening, sensitization, activation, and reduction And six steps of plating;

[0044] 2) Intermediate layer alloy foil 3: Au-Ge intermediate layer alloy ring 3 prepared with trace amounts of Ni, Ag, and Cu elements has a thickness of d / 2, wherein the content of Au is 90%, the content of Ge is 7%, the content of Ni is 1%, and the content of Ag Content 1%, Cu content 1%, d is the assembly gap;

[0045] 3) Joint assembly clearance design: according to the formula L 1 +α 1 · L 1 (t 2 -t 1 ) = L 2 +α 2 · L 2 (t 2 -t 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com