Automatic wiring structure for wire coiler

A technology of automatic wiring and wire reel, which is applied in the direction of using reel/photosensitive drum arrangement, cable arrangement between relative moving parts, cable installation, etc., which can solve the problem of power cord winding and slipping to other positions , can not be pulled out and other problems to achieve the effect of avoiding entanglement and improving satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The cable reel with automatic wiring function of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments, wherein the same structure as the prior art will continue to use its labels and will not be described in detail again:

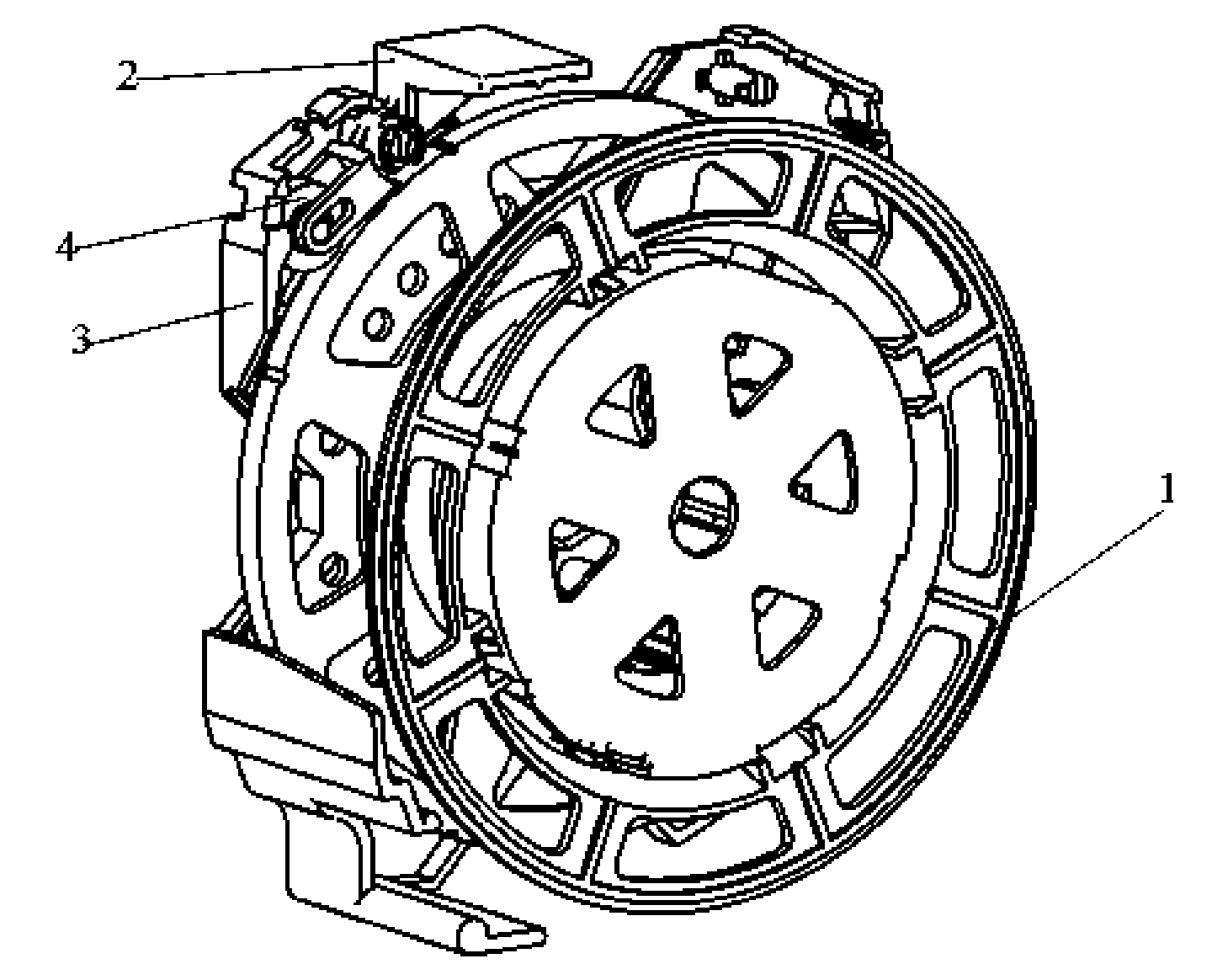

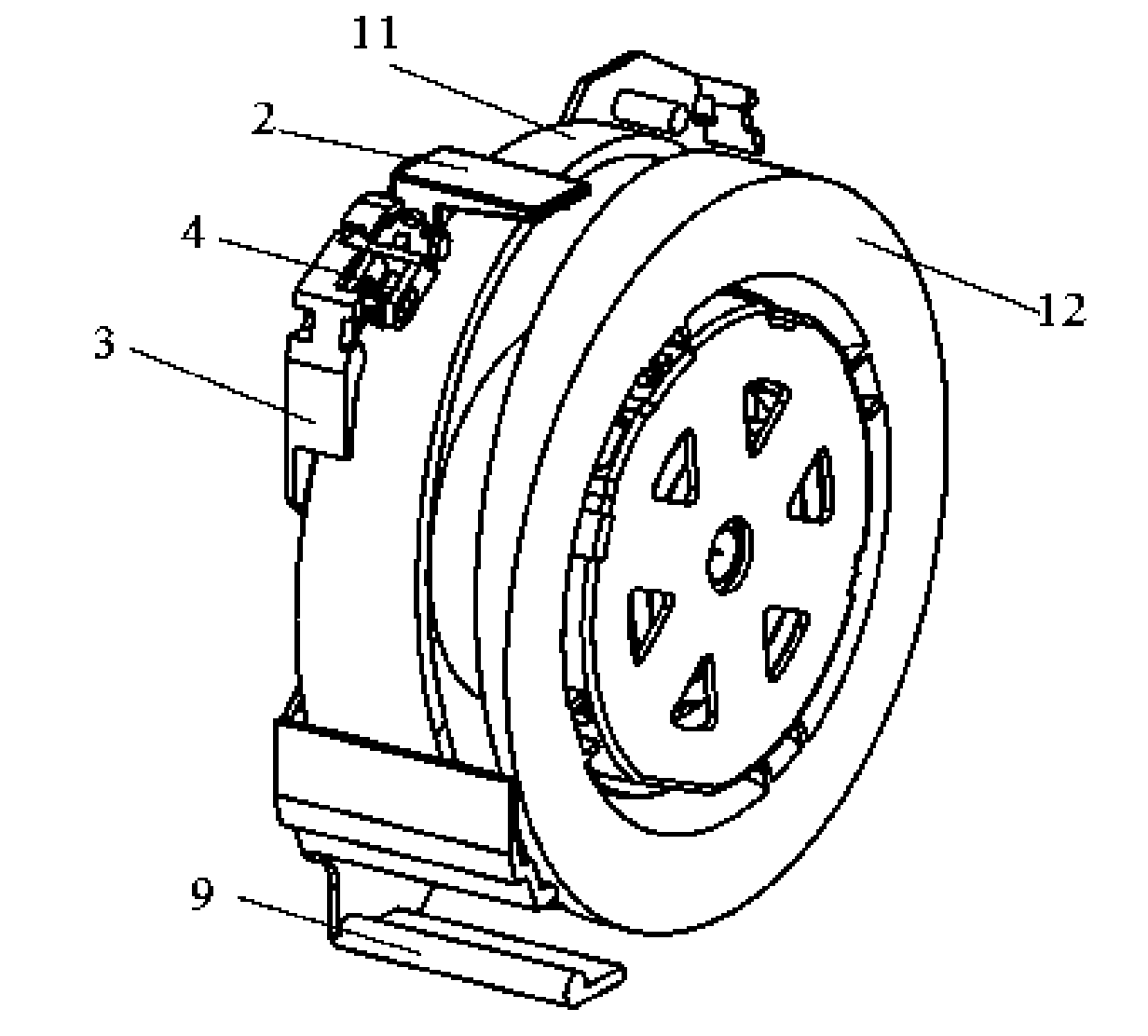

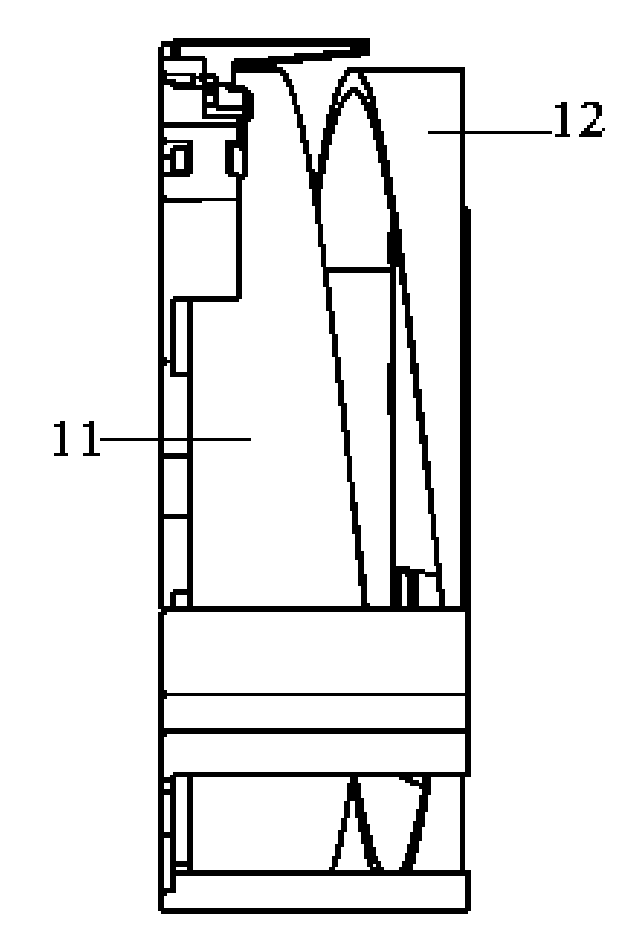

[0029] Such as Figure 2 to Figure 4 As shown, the wire reel of the present invention includes a left wheel disk and a right wheel disk forming a wire reel, and a bobbin (not shown) that connects the two in the middle and is provided with a concentric rotating shaft hole, so that it can be wound on The power cord (not shown) on the bobbin will not come out or mess up between the left wheel disc and the right wheel disc. The tops of the left and right roulettes protrude inwardly to form a left limit baffle 11 and a right limit baffle 12. Of course, the two limit baffles can also be fixedly arranged on the outer edges of the left and right roulettes. . The limit baffles on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com