A calibration system for smart tracking camera modules

A technology of intelligent tracking and calibration system, applied in stereo systems, components of TV systems, image communication, etc., can solve the problems of low calibration accuracy and poor efficiency, and achieve the effect of improving calibration accuracy, simple structure and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

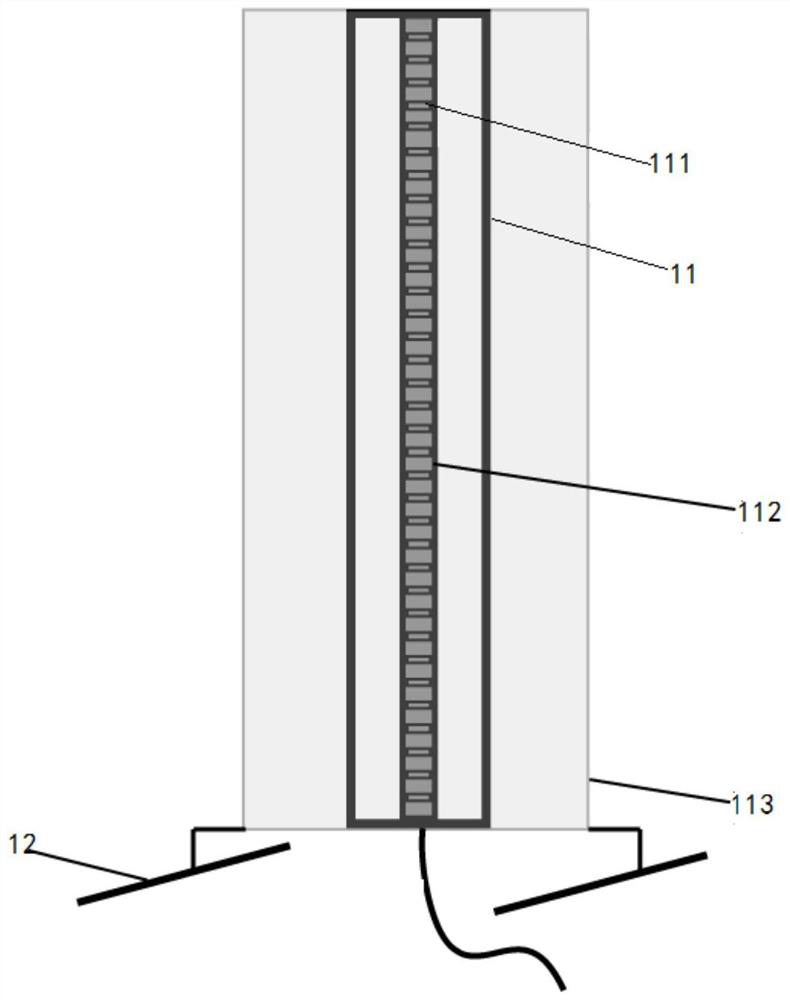

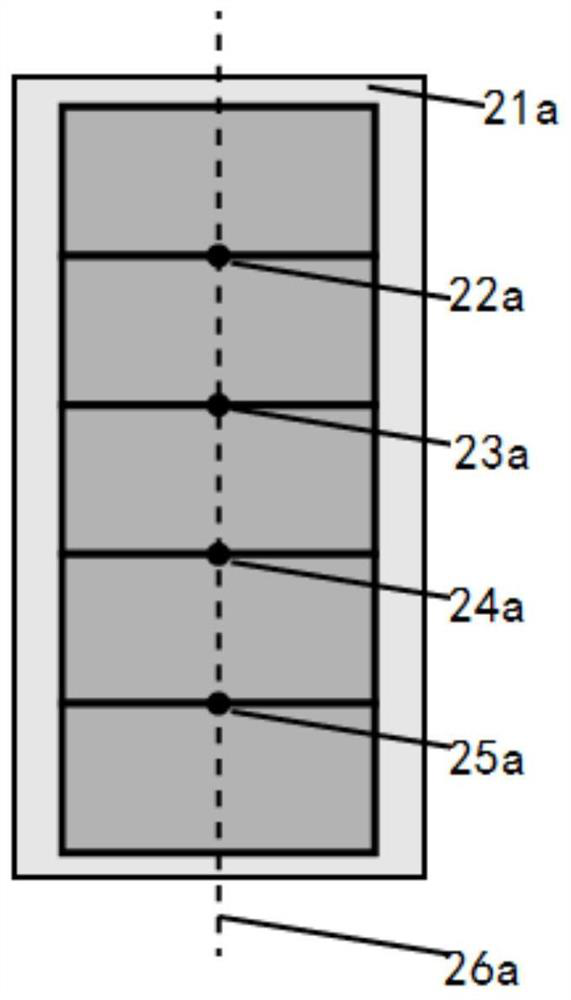

[0036] This embodiment provides a kind of calibration system for intelligent tracking camera module 2, such as Figure 7 As shown, the calibration system includes a calibration beam module 1, an intelligent tracking camera module 2, a control module 4, and a data integration module 3; the intelligent tracking camera module 2 is an internal component in an autostereoscopic display system, including a fixed tooling camera Match the spatial dimensions of the multi-degree-of-freedom detection device; the autostereoscopic display system uses a dual-camera system; wherein in this embodiment, the control module 4 and the data integration module 3 also directly use the internal components of the autostereoscopic display system without additional purchases these modules;

[0037] In the autostereoscopic display system, the position of the audience is detected in real time through the intelligent tracking camera module 2. Once the audience moves, the system will immediately adjust the p...

Embodiment 2

[0052] This embodiment 2 is a modification example of embodiment 1, the difference is that the light column 11 in the calibration light column module 1 is replaced by a light rod 13 with an appropriate length, such as Figure 5 As shown, it is only necessary to make it meet the requirement that it can emit extremely thin continuous light, that is, the effect obtained by the combination of the LED lamp array and the linear diffusion sheet 113 in Embodiment 1 is equivalent.

Embodiment 3

[0054] This embodiment 3 is based on the description of the calibration process for the calibration system for the intelligent tracking camera module 2 provided in embodiment 1. In this description, the LED backlight unit in the autostereoscopic display system is introduced together, but in the autostereoscopic display system The LED backlight unit does not belong to the content of the invention of the present invention; Image 6 As shown, the calibration process is as follows:

[0055] S1. System preparation: the calibration light column module 1, intelligent tracking camera module 2, data integration module 3 and control module 4 of the system enter the ready state; at this time, the calibration light column module 1 emits continuous light as a calibration image;

[0056] S2. The system lights up the LED backlight: the LED backlight unit of the system is composed of multiple columns of sequentially numbered LED units, and the control module 4 in the system lights up all the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com