Range-adjustable equipment for wiping glass

A glass and scope technology, applied in the field of adjustable scope equipment, can solve the problems of not being able to recycle and completely wipe the glass, and achieve the effect of improving the working scope and eliminating the operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

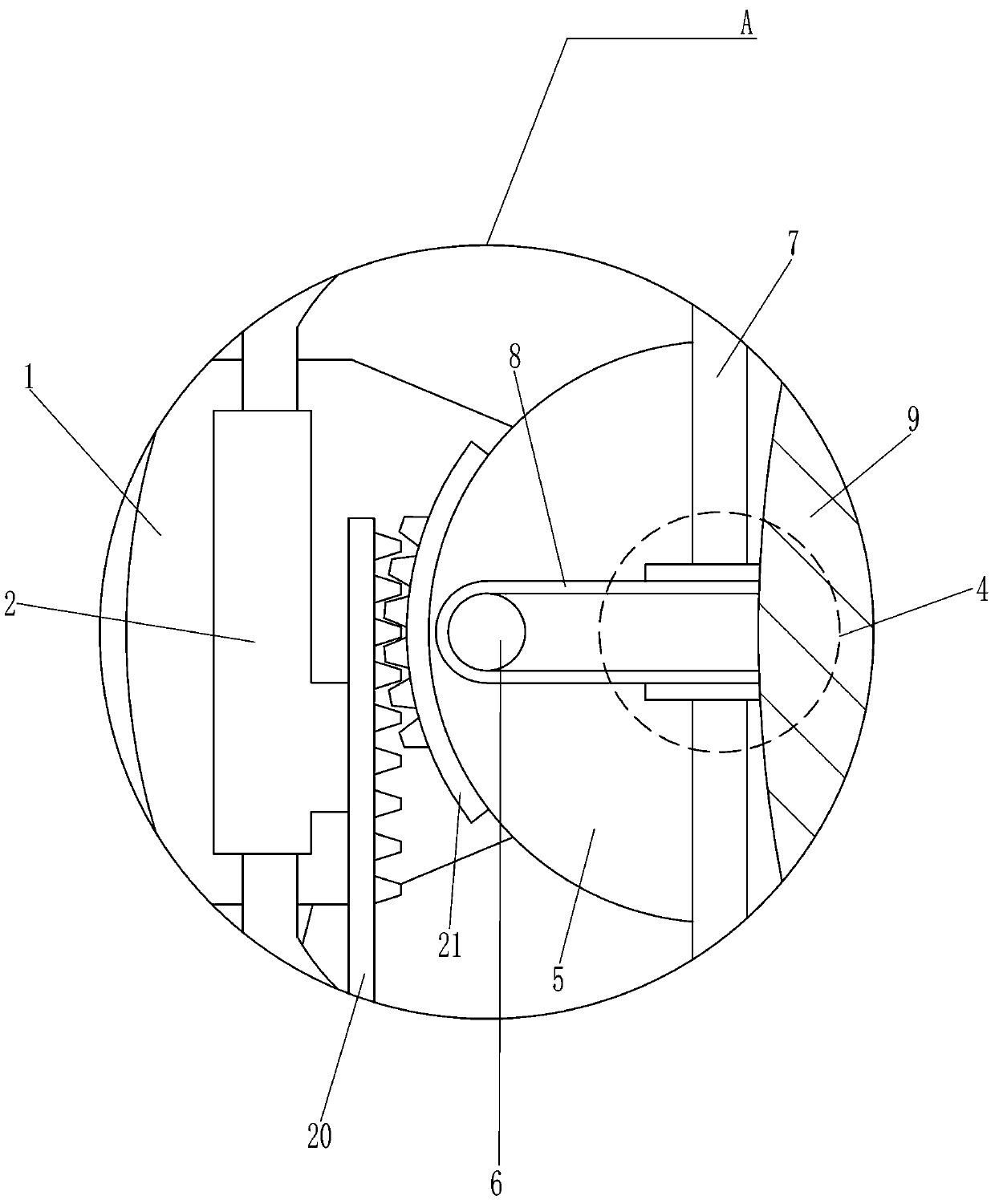

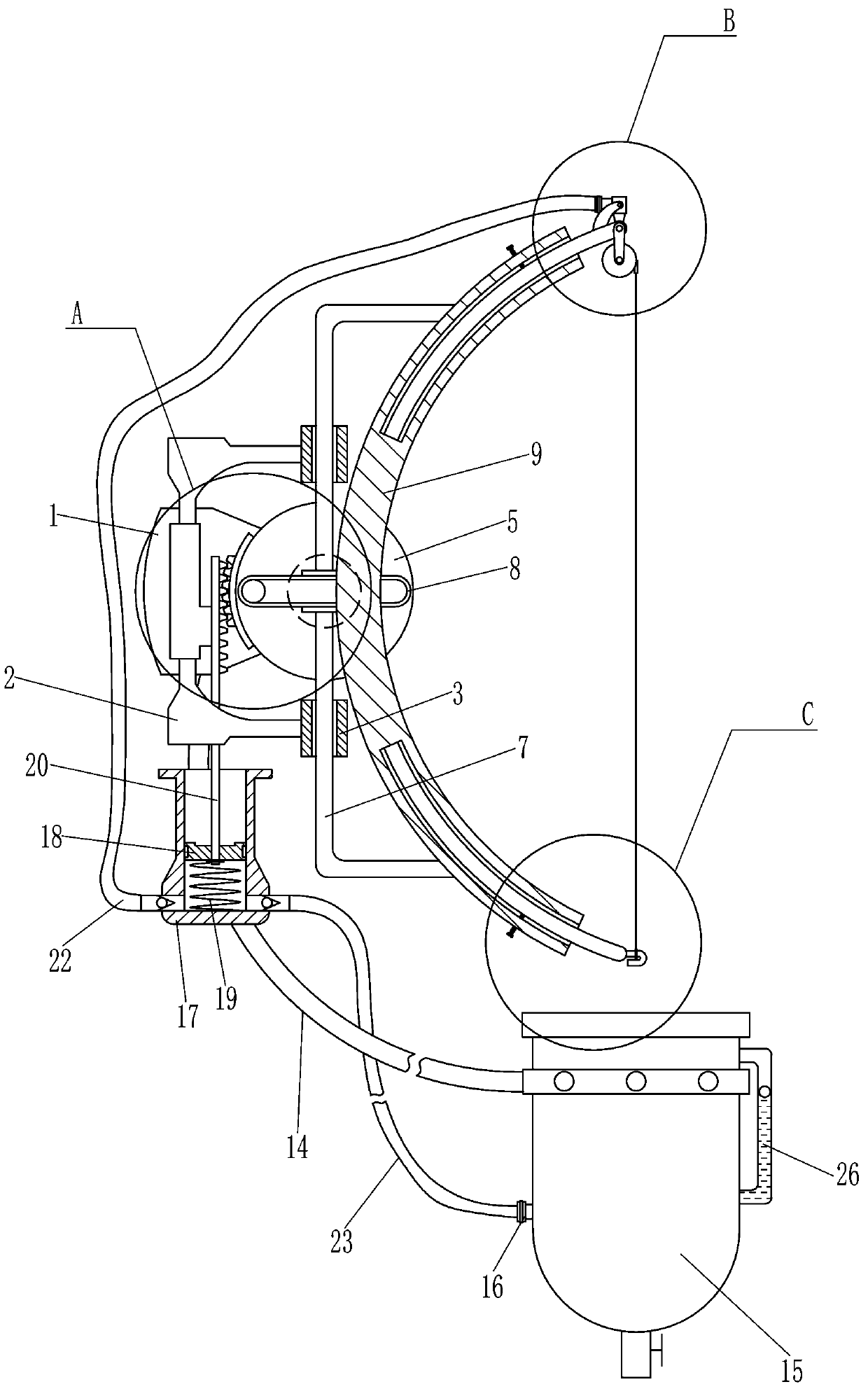

[0020] A range-adjustable device for wiping glass, such as Figure 1-4 As shown, it includes a mounting plate 1, a mounting frame 2, a guide sleeve 3, a driving motor 4, a turntable 5, a push rod 6, an L-shaped sliding rod 7, a sliding frame 8, an arc-shaped plate 9, an arc-shaped sliding rod 11, a tight Fixing bolts 12 and wiping device 13, mounting frame 2 is provided on the front side of mounting plate 1, guide sleeves 3 are provided on both sides of mounting frame 2, driving motor 4 is provided on the front of mounting plate 1 side, and the output shaft of driving motor 4 is connected Turntable 5 is arranged, and push rod 6 is arranged on the turntable 5, and L-shaped sliding rod 7 is slidably connected in the guide sleeves 3 on both sides, and a sliding frame 8 is arranged at the inner end of the L-shaped sliding rod 7 on both sides, and the sliding frame 8 is connected to the push rod. The rod 6 is slidingly matched, and the front side of the L-shaped sliding rod 7 on bo...

Embodiment 2

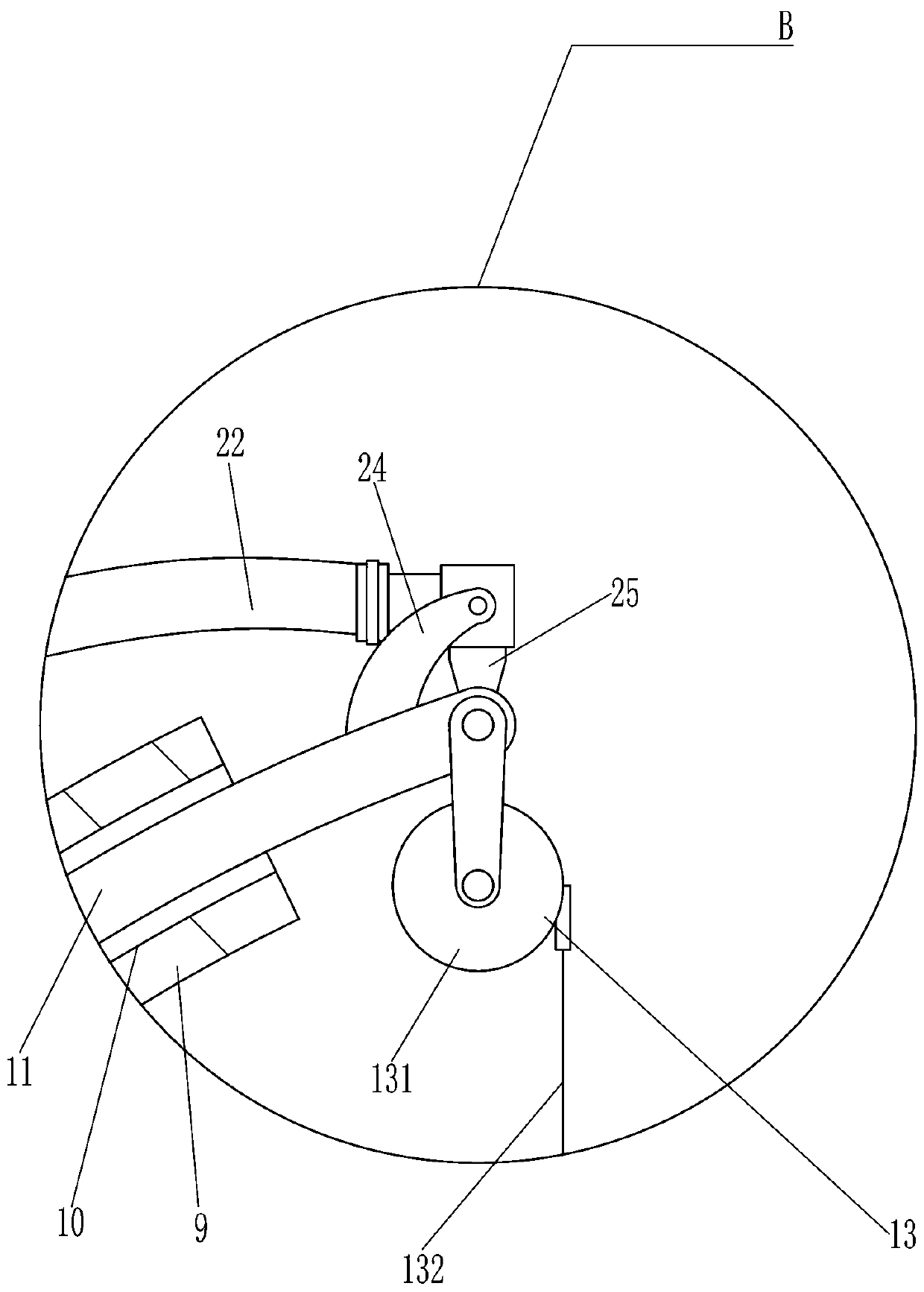

[0024] On the basis of Example 1, such as Figure 1-2 As shown, it also includes an arc-shaped support rod 14, a liquid storage frame 15, a strainer 16, a cylinder body 17, a piston 18, a return spring 19, a rack 20, a sector gear 21, a drain pipe 22, and a liquid inlet pipe 23 , mounting base 24 and liquid spray pipe 25, the bottom of mounting plate 1 is provided with arc-shaped support bar 14, and one end of arc-shaped support bar 14 is provided with liquid storage frame 15, and one side of liquid storage frame 15 is provided with strainer 16, arc-shaped The front side of the support rod 14 is provided with a cylinder body 17, a piston 18 is slidably connected in the cylinder body 17, and a return spring 19 is connected between the piston 18 and the inner bottom of the cylinder body 17, and the piston 18 is provided with a rack 20, and the rack 20 One side is in contact with the mounting frame 2, the rear side of the turntable 5 is provided with a sector gear 21, the sector ...

Embodiment 3

[0027] On the basis of Example 2, such as figure 1 As shown, a liquid level gauge 26 is also included, and a liquid level gauge 26 is provided on one side of the liquid storage frame 15 .

[0028] Although the water containing the wiper can be recycled and collected during the operation of the equipment, the water containing the wiper will still be lost due to various reasons during the operation of the equipment. Through the liquid level gauge 26, it can be visually judged The water content in the frame 15 has reached the effect of being convenient to remind the worker to add water in time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com