Surface polishing device for metal plate for electronic product processing

A technology for electronic products and surface polishing, which is applied to surface polishing machine tools, metal processing equipment, grinding workpiece supports, etc. The effect of improving the range and grinding the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

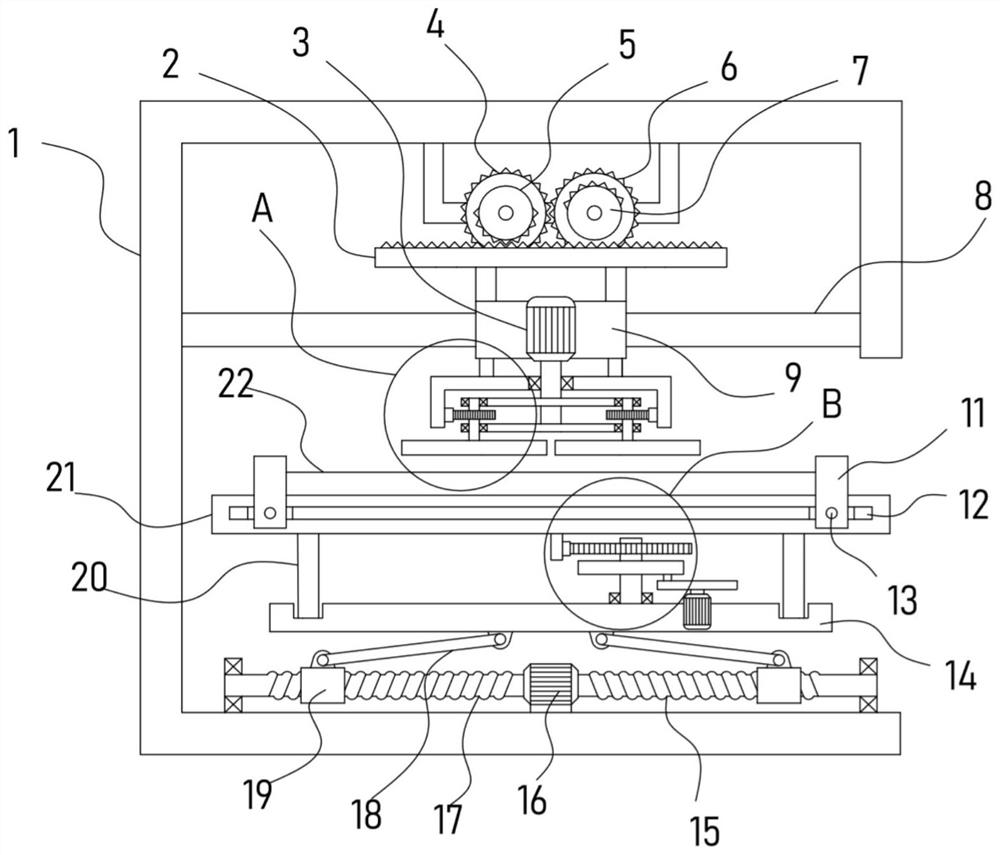

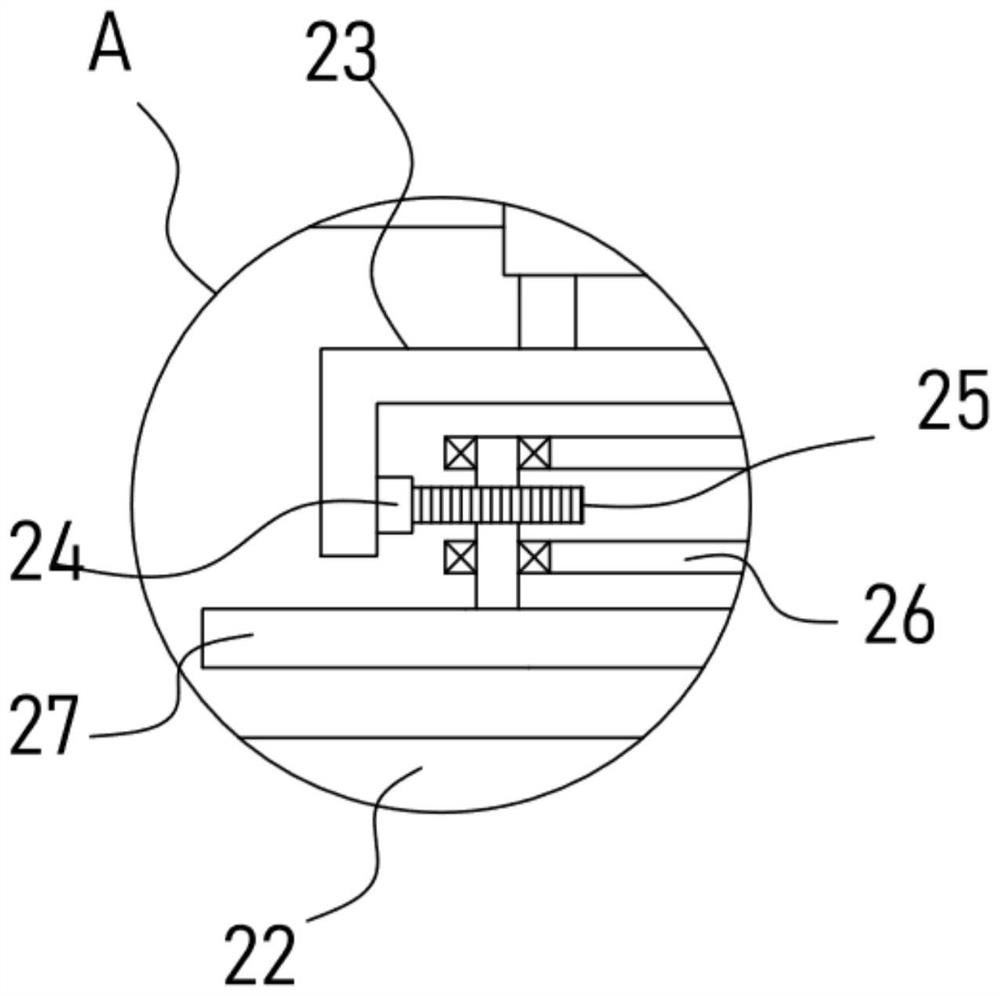

[0026] see Figure 1-5 , a metal plate surface polishing device for electronic product processing, comprising a support frame 1, a support platform 21 for supporting a metal plate 22 is horizontally provided on the support frame 1, and a support platform 21 for supporting a metal plate 22 fixed clamping mechanism, the support frame 1 is provided with a fixed frame 23, the fixed frame 23 is provided with a polishing mechanism for grinding the metal plate 22, and the support frame 1 is provided with a horizontal reciprocating mechanism for driving the polishing mechanism The horizontal translation mechanism of the movement, the support frame 1 is provided with a lift plate 14 for carrying the support platform 21, and the lift plate 14 is provided with a longitudinal translation mechanism for driving the vertical position adjustment of the support platform 21, the support frame 1 and the lift A lifting mechanism is connected between the plates 14 .

[0027] The support table 21 ...

Embodiment 2

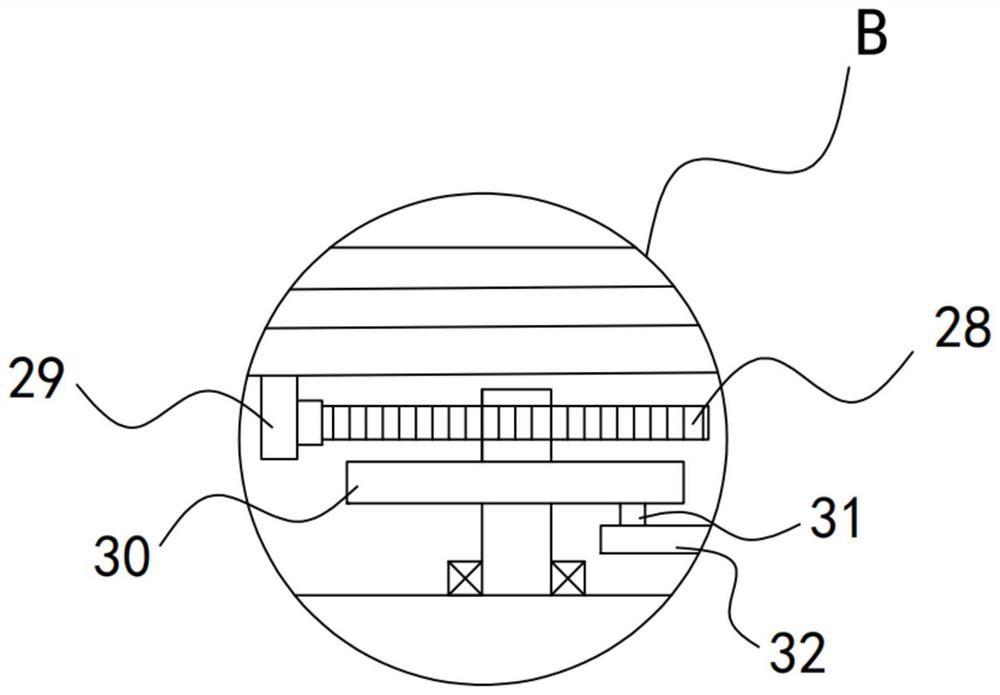

[0034] On the basis of Embodiment 1, in addition, this device is also provided with a longitudinal translation mechanism, which includes a turntable 32 that is rotatably mounted on the lifting plate 14. A transmission column 31 is eccentrically fixed on the turntable 32, and a groove is rotatably installed on the lifting plate 14. There are several radial grooves 10 evenly opened on the sheave 30, and the transmission column 31 is intermittently slidably adapted to the radial grooves 10. The bottom of the support platform 21 is fixed with a running rack 29, which is meshed and connected There is a travel gear 28 coaxially fixed with the sheave 30 , and a guide plate 20 fixed on the bottom of the supporting platform 21 is slidably embedded on the lifting plate 14 .

[0035] The rotation of the turntable 32 can drive the transmission column 31 on it to rotate, and the transmission column 31 is alternately slidably connected with a plurality of radial grooves 10 on the sheave 30 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com