An Ejection Mechanism of a Two-way Combined Die

A technology of ejection mechanism and combined mold, which is applied in the direction of presses, manufacturing tools, etc., can solve the problems of low picking efficiency and high risk factor, and achieve the effect of reducing risk factor and improving picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

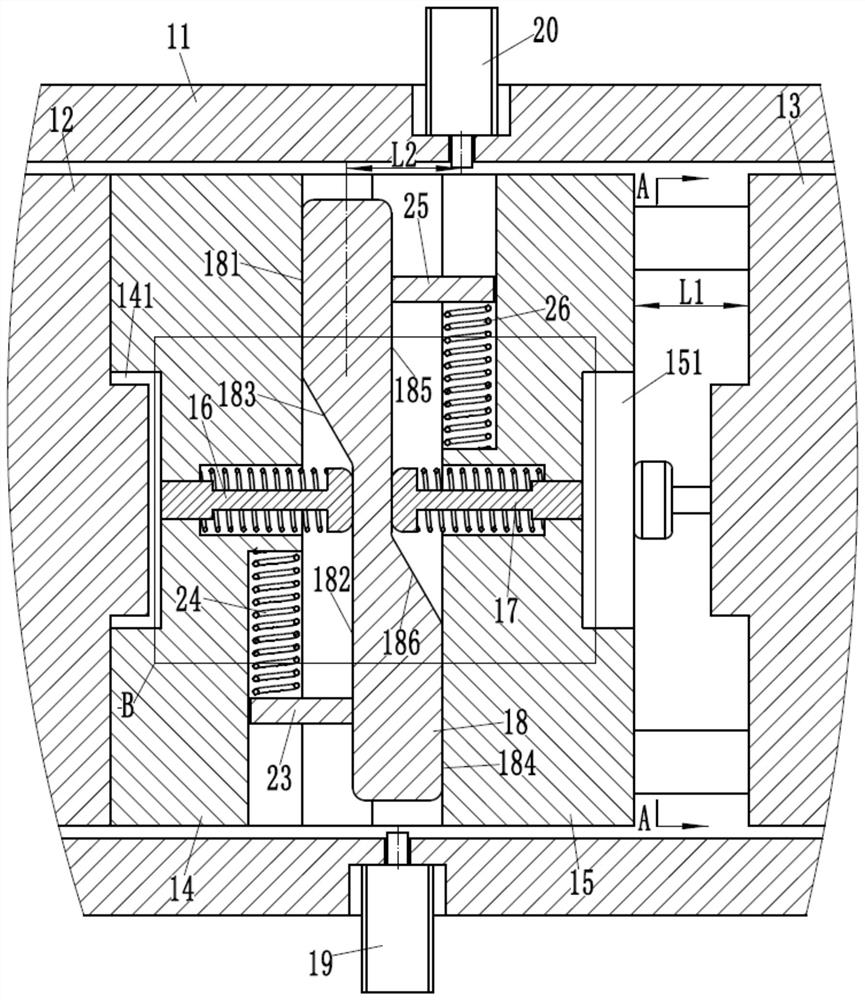

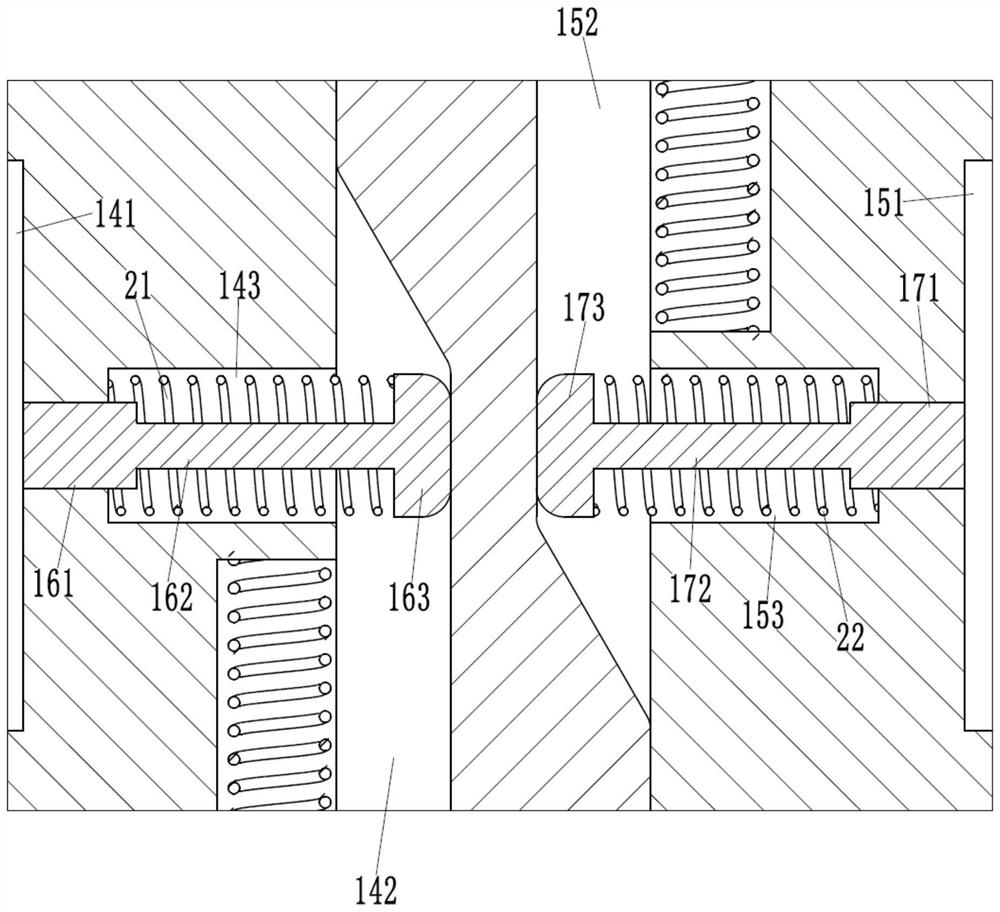

[0021] Examples, see e.g. Figure 1 to Figure 4 Shown, the ejection mechanism of a kind of two-way combined mould, comprises frame 11, the first punch 12 and the second punch 13 that are fixedly connected with frame 11, the right side of described first punch 12 is provided with and The first die 14 corresponding to the first punch 12, the left side of the second punch 13 is provided with the second die 15 corresponding to the second punch 13, the first die 14 and the second die The mold 15 is fixedly connected; the first die 14 is sleeved with a first thimble 16, the second die 15 is sleeved with a second thimble 17, and a front and back movement is provided between the first thimble 16 and the second thimble 17. The moving drive bar 18, the left side wall of the drive bar 18 is formed with a left rear high plane 181, a left front low plane 182 and a left slope 183 connecting the left rear high plane 181 and the left front low plane 182, the first thimble 16 is pressed again...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com