Clay scarifier for cofferdam downward release

A technology of lowering cofferdams and rippers, which is applied in earth movers/shovels, buildings, and infrastructure engineering, etc., can solve problems such as difficult water scour and absorption, good clay cohesion, and increased cofferdam buoyancy, etc. To achieve the effect of improving the efficiency of mud suction and speeding up the lowering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

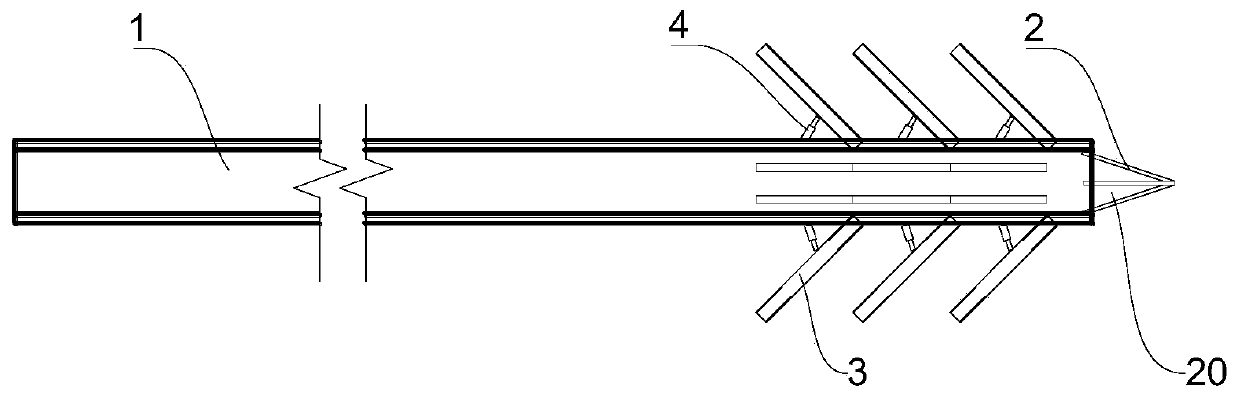

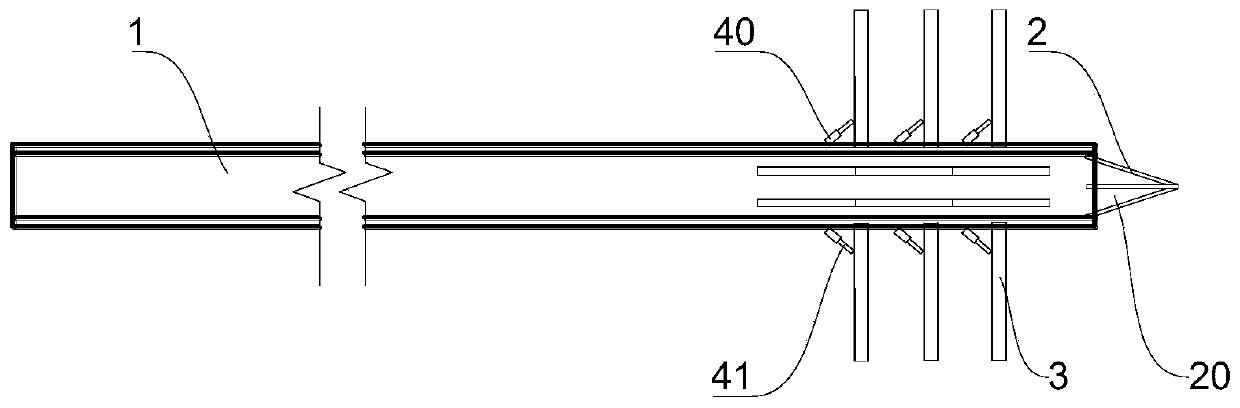

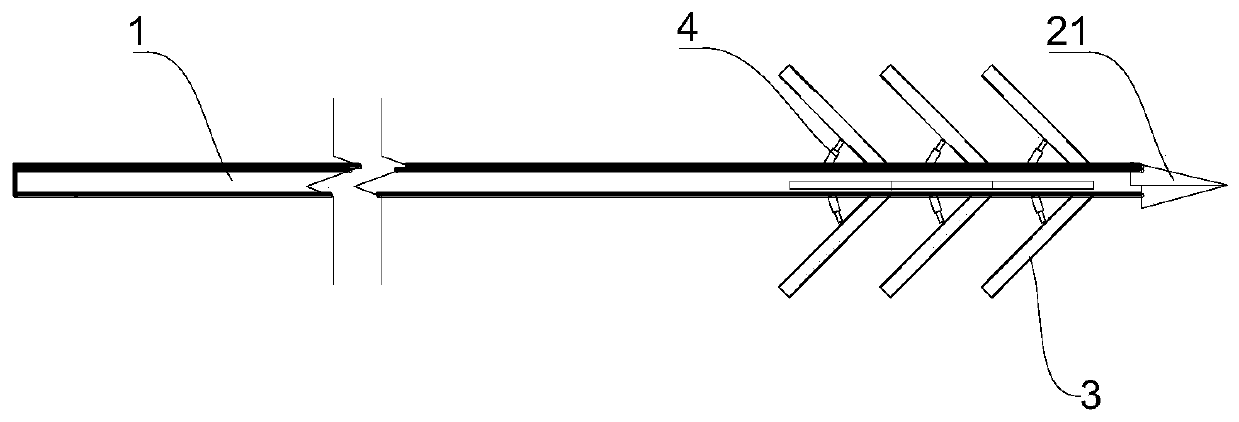

[0033] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a clay ripper for lowering the cofferdam, which includes a rod body 1, an insertion part 2 and a plurality of loose soil rods 3, the insertion part 2 is arranged at one end of the rod body 1, and the other end of the rod body 1 One end is a pressure-bearing end, and the insertion part 2 is vertically inserted into the clay by applying pressure to the pressure-bearing end; a plurality of loosening rods 3 are distributed at intervals along the axial direction of the rod body 1, and the loosening rods 3 are rotatably arranged on the rod body 1 near the end of the insertion part 2, the loosening rod 3 is inserted into the clay together with the insertion part 2, and loosens the clay; the clay loosening device includes an inserted state and a pulled out st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com