Lowing control system for movable arm of hydraulic excavator for mines

A technology of control system and mobile arm, which is applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of energy waste, failure to impact energy utilization, etc., and achieve the effects of improving work efficiency, reducing heat generation, and accelerating decentralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

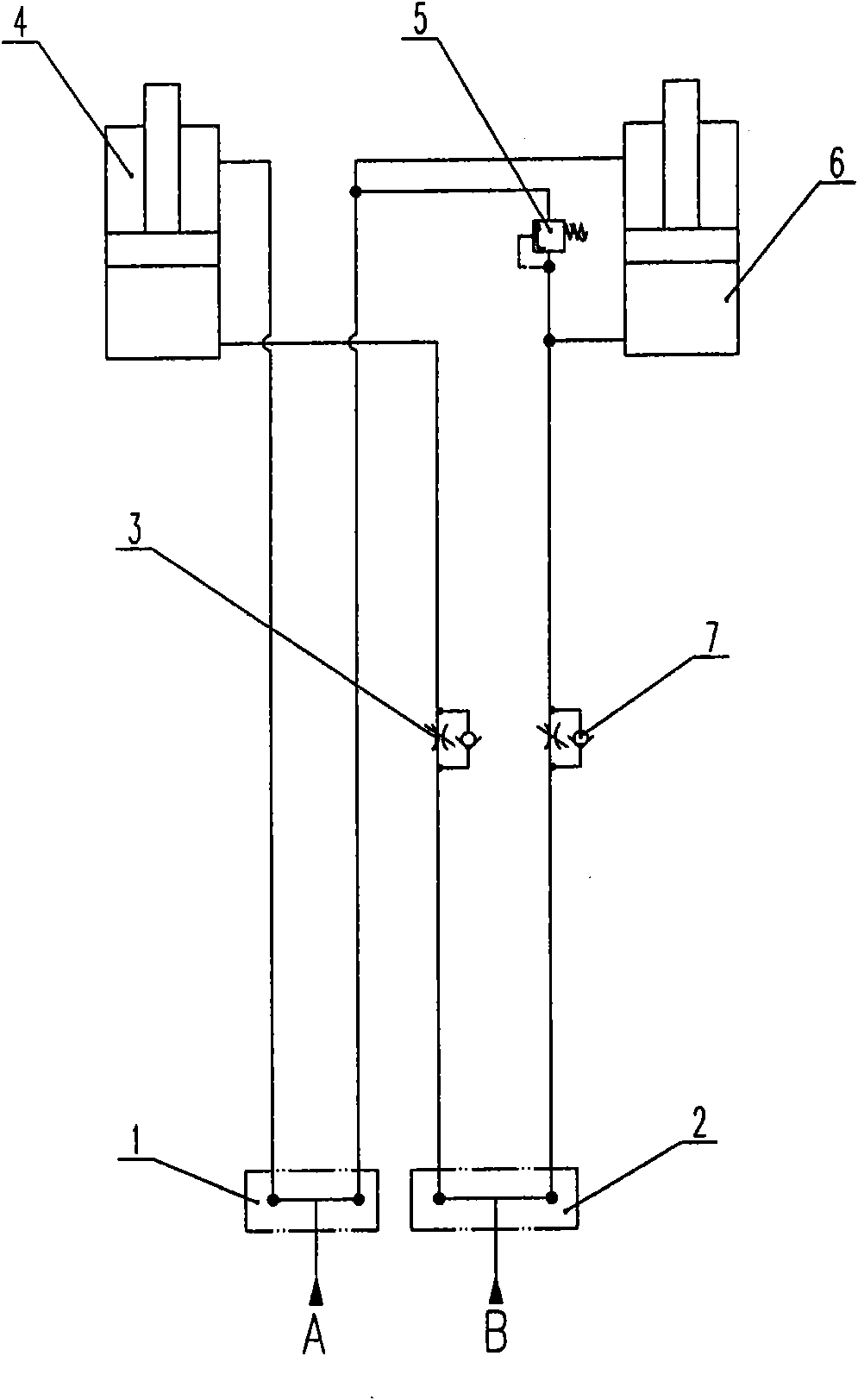

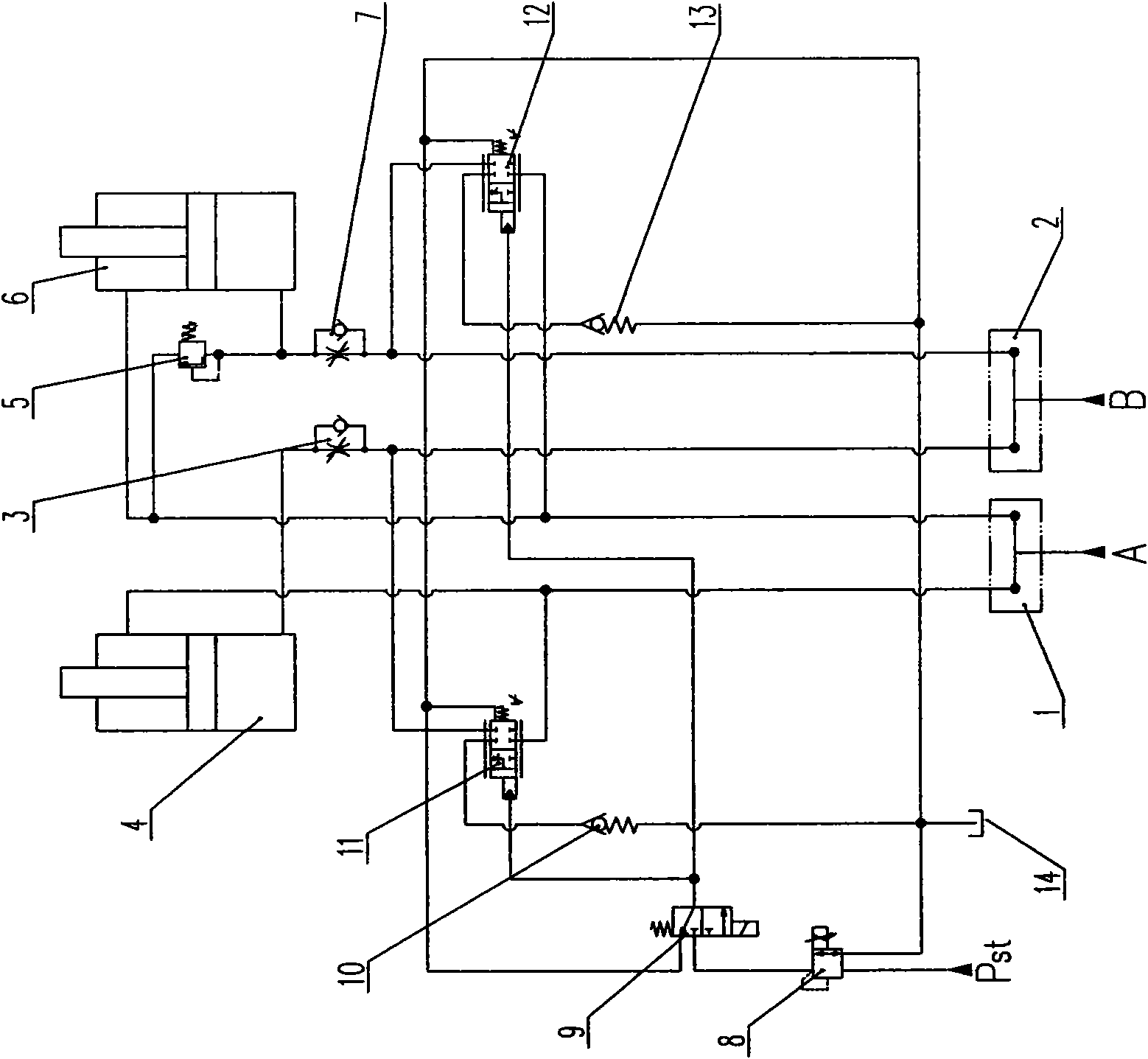

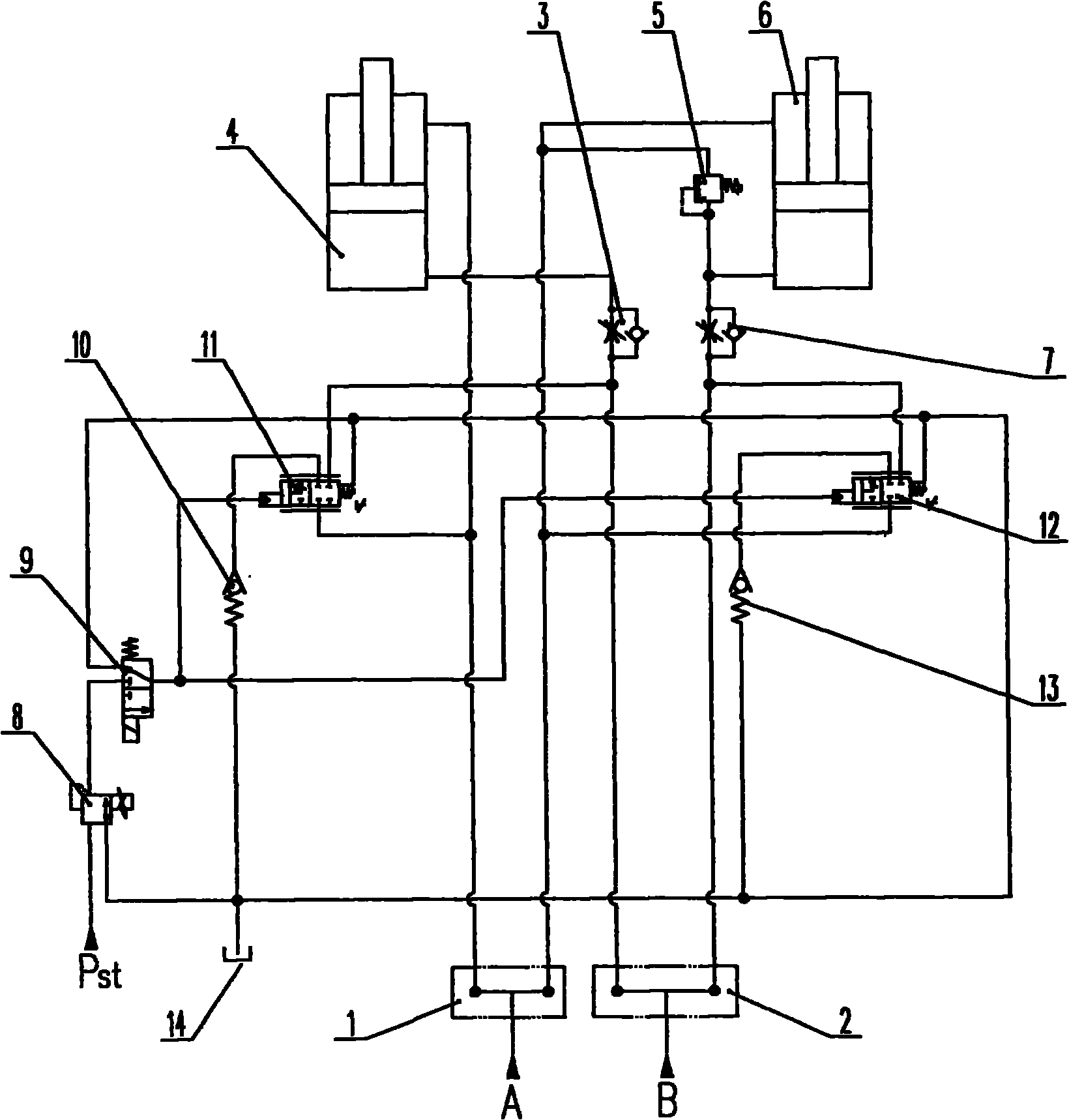

[0011] Such as figure 2 As shown, a mining hydraulic excavator arm lowering control system consists of a left diverter block 1, a right diverter block 2, a left one-way throttle valve 3, a left boom cylinder 4, a safety valve 5, and a right movable arm cylinder. The main pressure oil circuit composed of the arm cylinder 6, the right one-way throttle valve 7 and the hydraulic pipeline, and the remote control valve 8, the electromagnetic switching valve 9, the left boom cylinder one-way valve 10, and the left boom cylinder regeneration valve 11. The right boom cylinder regeneration valve 12, the right boom cylinder one-way valve 13, the oil tank 14 and the pilot control oil circuit composed of hydraulic pipelines are composed of two parts.

[0012] The specific connection of the main pressure oil circuit is: the main pressure oil from the A port is connected to the rod chambers of the left boom cylinder 4 and the right boom cylinder 6 through the pipeline at the same time; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com