Device and method for removing ions in water of cooling water tank

A technology of cooling water tanks and ion devices, which is applied in the direction of light water/sewage treatment, etc., can solve the problems of inability to effectively reduce the ion concentration and the increase of ion concentration, so as to meet the needs of equipment operation, reduce ion concentration, and reduce ion concentration in cooling water. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

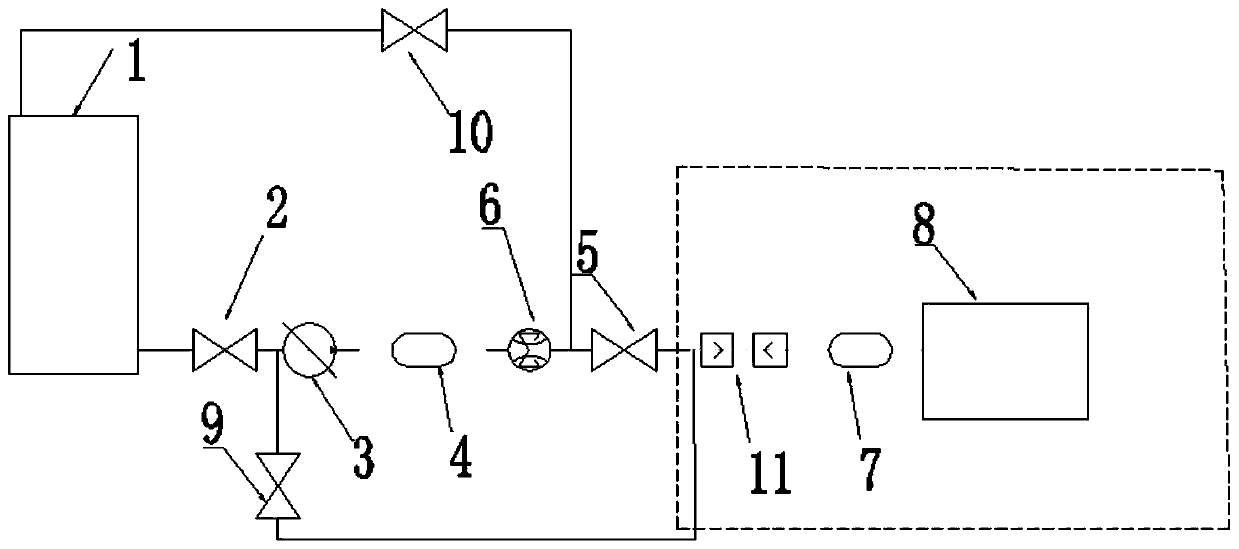

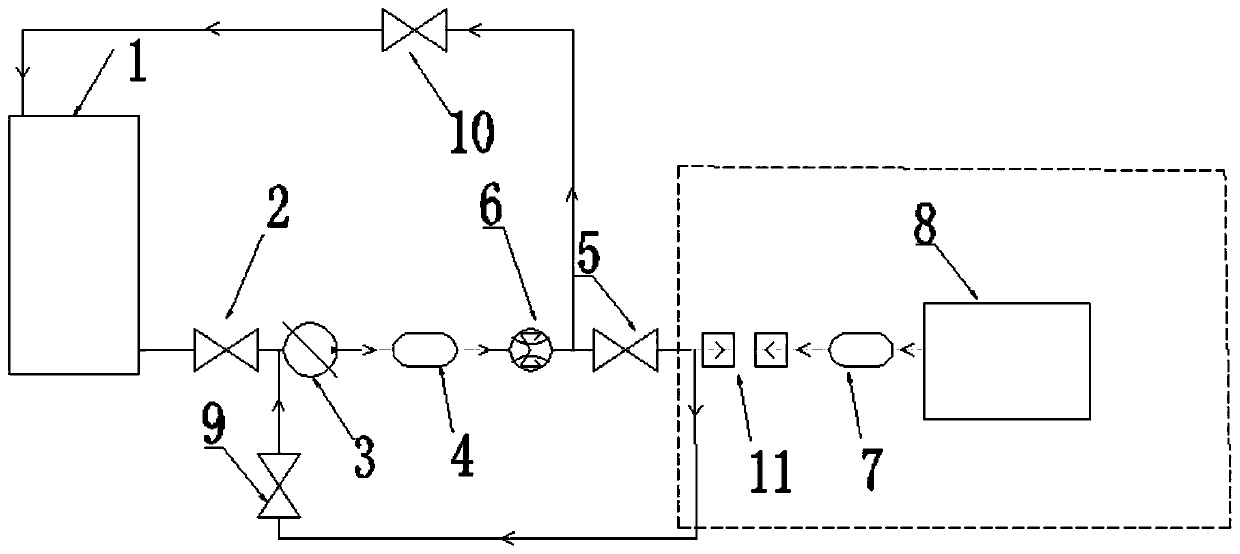

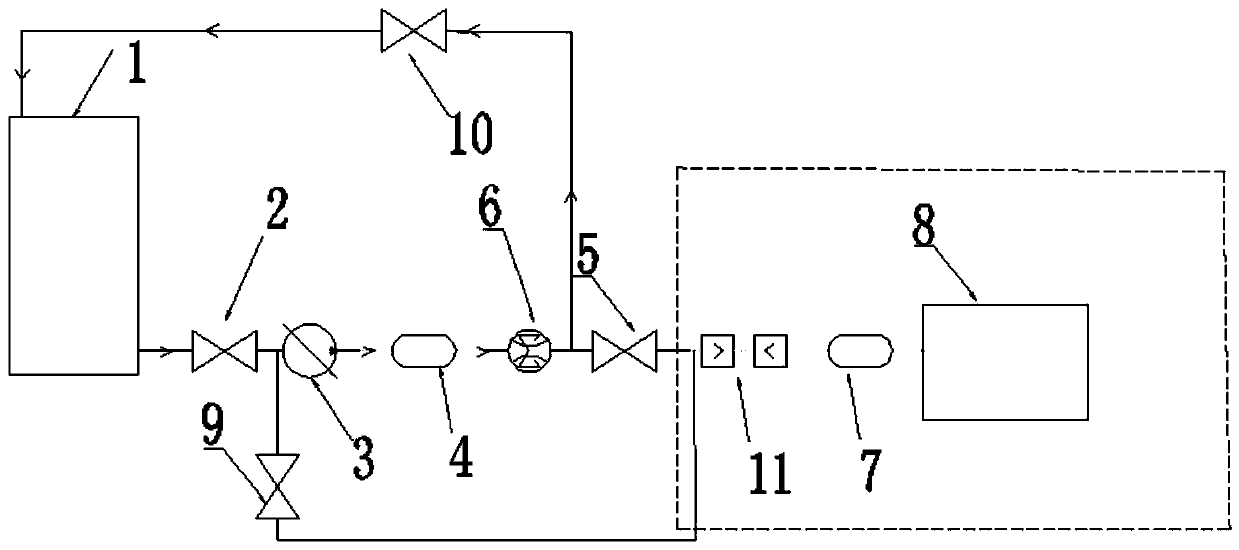

[0017] Specific implementation mode one: combine Figure 1 to Figure 4 Describe the embodiment of this city, a water ion removal device for a cooling water tank in this embodiment, which includes a water tank 1, a power pump 3, a deionization tank 4, an ion concentration display meter 6, a deionization tank 2 7 and a cooling water tank 8 ;

[0018] The water outlet of the water tank 1 is connected with the water inlet of the ball valve one 2, the water outlet of the ball valve one 2 is connected with the water inlet of the power pump 3, the water outlet of the power pump 3 is connected with the water inlet of the deionization tank one 4, and the deionization tank one 4 The water outlet is connected to the water inlet of the ion concentration display meter 6, the water outlet of the ion concentration display meter 6 is connected to the water inlet of the ball valve 2 5, the water outlet of the ball valve 2 5 is connected to the water inlet of the ion tank 2 7, and the deionizat...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination Figure 1 to Figure 4 Describe the implementation mode in this city. The difference between this implementation mode and the specific embodiment one is that the power pump 3 is a DC pump and adopts 24DC direct current. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination Figure 1 to Figure 4 Describe the embodiment of this city, the difference between this embodiment and the specific embodiment one is: the pumping flow rate of the power pump 3 is 20L / min. Others are the same as in the first embodiment.

[0022] Specific implementation mode four: combination Figure 1 to Figure 4 Describe the embodiment of this city. The difference between this embodiment and the first embodiment is that the water tank is divided into a water inlet chamber and a water outlet chamber. Others are the same as in the first embodiment.

[0023] Specific implementation mode five: combination Figure 1 to Figure 4 Describe this city's implementation mode, the difference of this implementation mode and specific embodiment one is: be provided with water absorption filter, liquid level gauge, quick connector and hand valve in the water tank. Others are the same as in the first embodiment.

[0024] Specific impl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com