Blowout prevention packer capable of rapid pump setting and well completion after fracturing

A post-fracturing and packer technology, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of no blowout prevention measures, increase construction procedures and costs, and shorten production period , to achieve the effect of improving construction efficiency, reducing operation risk, and obvious blowout prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

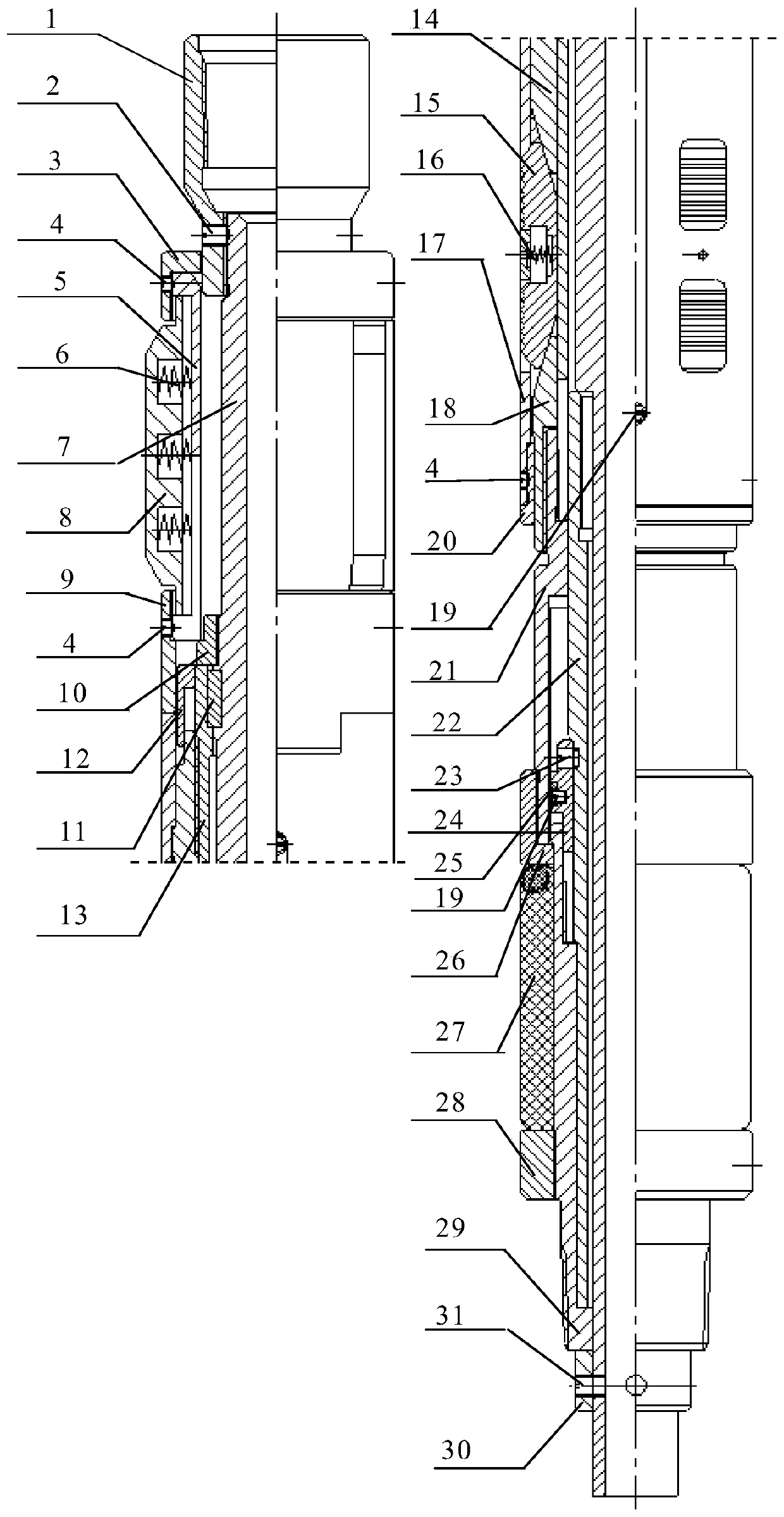

[0013] Specific embodiments: The present invention will be further described below in conjunction with the accompanying drawings: it consists of an upper joint 1, a fixed pin 2, a centering pressure ring 3, a fixed pin 2 4, a centering body 5, a spring 6, a center pipe 7, and a friction block 8 , clutch cover 9, limit sleeve 10, key 11, fixed sleeve 12, slip center tube 13, upper cone 14, slip 15, spring 2 16, slip hanger 17, lower cone 18, anti-rotation pin 19 , Slip hanging limit sleeve 20, setting sleeve 21, salvage sleeve 22, unsealing pin 23, unsealing sleeve 24, locking ring 25, rubber sleeve stop ring 26, rubber sleeve sleeve 27, limit ring 28, lower joint 29. The throwing glove 30 and the throwing pin 31 are composed; the limit sleeve 10 is connected with the central tube 7 with a screw, the upper end of the friction block 8 is connected with the righting pressure ring 3 with a thread, and the spring one 6 is placed on the centralizing body 5 and the friction block 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com