Blowout preventer of rod type defueling pump

A technology of blowout preventer and oil well pump, which is applied in variable capacity pump parts, parts of pumping devices for elastic fluids, pumps, etc., and can solve the problems of installing blowout preventer and inability to install screw pump blowout preventer , to achieve the effects of energy saving, good blowout prevention effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

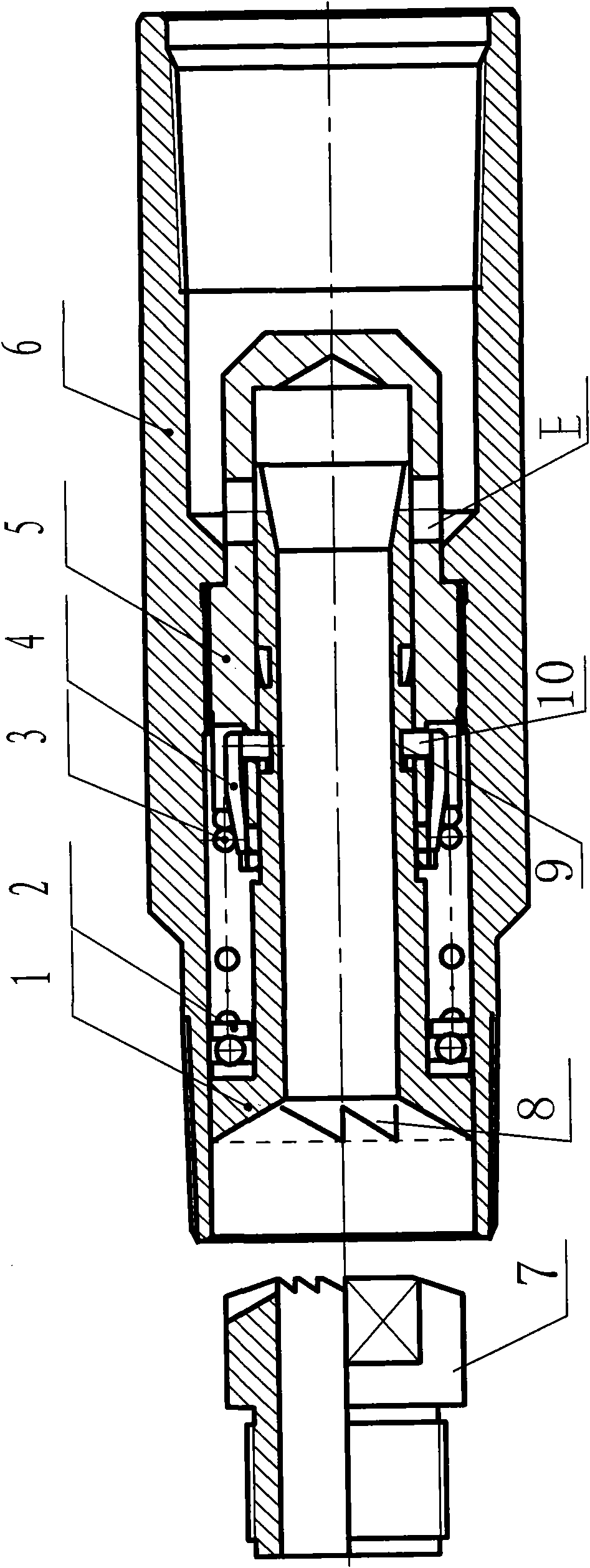

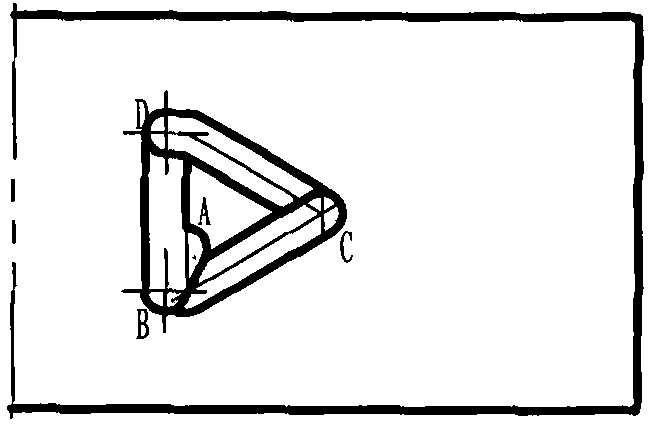

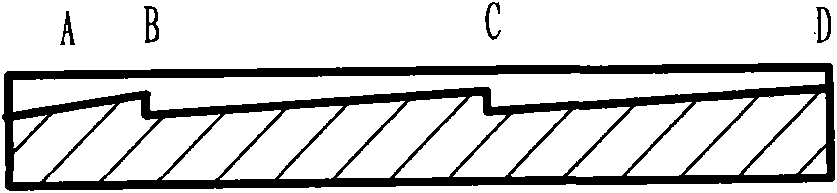

[0015] See Figure 1-8 , The specific structure of the present invention is as follows: the upper end of the cylindrical outer cover 6 has an external taper thread, which is connected with the oil well pump barrel, and the lower end has an internal taper thread, which is connected with the valve seat. The positioning sleeve 5 is fixedly connected with the connecting thread and the stopper in the outer sleeve 6, the lower end of the positioning sleeve 5 is closed and an oil inlet E is opened on the side wall; a symmetrical bayonet connection hole 11 is arranged on the outer periphery of the upper end of the positioning sleeve 5 (see Figure 6 ), the hook-shaped bayonet 4 is assembled on the bayonet connecting hole 11, the cylindrical anti-blowout sliding sleeve 1 is assembled in the positioning sleeve 5, and two symmetrical curved chutes 9 are arranged on the outer peripheral surface of the anti-blowout sliding sleeve 1, and the curved chute 9 is the circumferential closed type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com