Reliability testing device for ablation-resistant materials

An inspection device and ablation-resistant technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of high inspection cost and lack of popularity, and achieve convenient operation, guaranteed service life and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] With the development of technologies such as hypersonic vehicles and transcendental ramjet engines, there are great requirements for the ablation resistance of materials. Therefore, the requirements for the reliability detection technology of ablation-resistant and heat-insulating materials are also increasing. At present, the reliability detection device for ablation-resistant heat insulation materials is only suitable for steady-state long-term ablation conditions, without considering the influencing factor of pressure, and lacks short-term and variable load ablation of ablation-resistant heat insulation materials Reliability test device for shock detection.

[0018] Therefore, the present invention proposes a new reliability detection device for ablation-resistant materials.

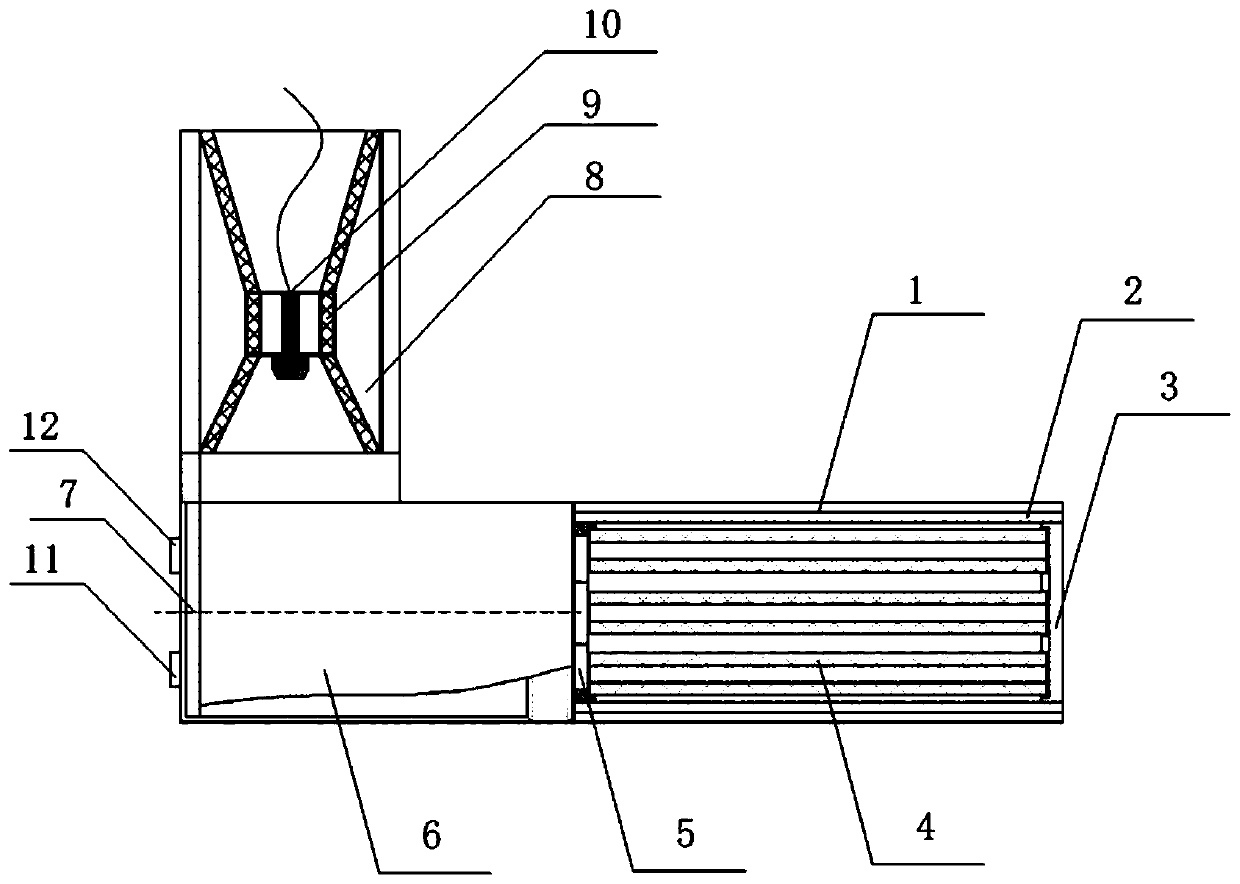

[0019] combine figure 1 , a reliability testing device for ablation-res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com