Pickup truck rear door fatigue endurance performance test device, control system thereof and test method thereof

A test device and rear door technology, which is applied in the direction of measuring device, vehicle test, machine/structural component test, etc., can solve the problems of inability to effectively detect the matching performance of functional parts related to the reliability of the door system and durability test defects, etc. Achieve the effects of size applicable range guarantee, stability and reliability guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, the present invention is described in further detail:

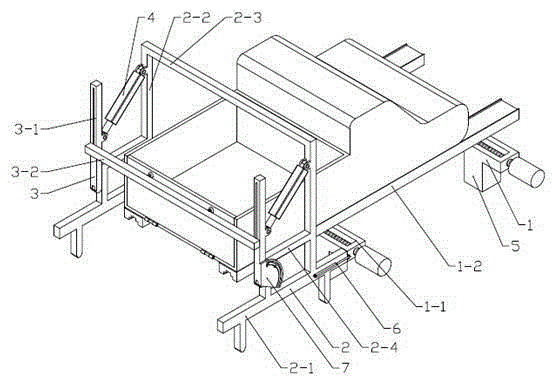

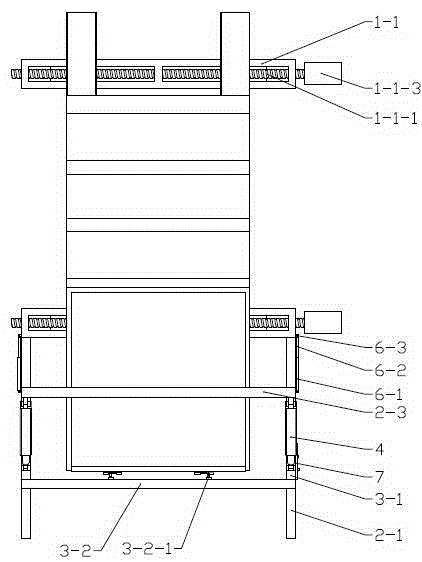

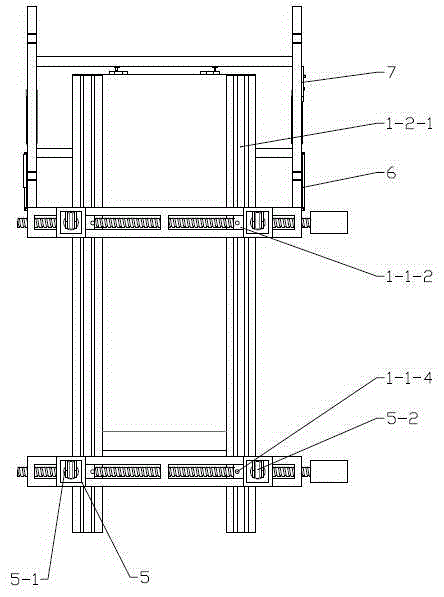

[0038] The pickup truck rear door fatigue durability testing device of the present invention includes a frame 1, a test bench 2, a turning mechanism 3, a turning driving electric cylinder 4, a supporting foot 5, a locking mechanism 6, and a turning angle limiter 7. The supporting foot 5 is set under the frame 1, the test bench 2 and the turning mechanism 3 are set at one end of the frame 1, the locking mechanism 6 is set between the frame 1 and the test bench 2, the turning driving electric cylinder 4 and the turning angle The limiter 7 is arranged between the test bench 2 and the turning mechanism 3 .

[0039] The frame 1 of the present invention includes a crossbeam 1-1 and a longitudinal beam 1-2, the crossbeam 1-1 and the longitudinal beam 1-2 are connected to each other, the number of the crossbeam 1-1 is two, and the two crossbeams 1-1 are arranged parallel to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com