Manufacturing method and application of pressed film material functional appliance

A manufacturing method and a technology of an orthodontic device, which are applied in the field of oral treatment, can solve problems such as affecting pronunciation, blocking tongue movement, and affecting aesthetics, and achieve the effect of little impact on pronunciation, extreme impact on pronunciation, and comfortable wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The manufacturing method of the laminated material functional appliance comprises the following steps:

[0029] 1) Making an impression: Make an impression of the upper and lower teeth with the impression material, and pour a plaster model.

[0030] 2) Making the retention film of the upper and lower teeth: using the model of the upper and lower teeth and the finished thermoplastic diaphragm, the retention film that is completely fitted to the dentition is produced through hot-pressing and vacuum-absorbing technology.

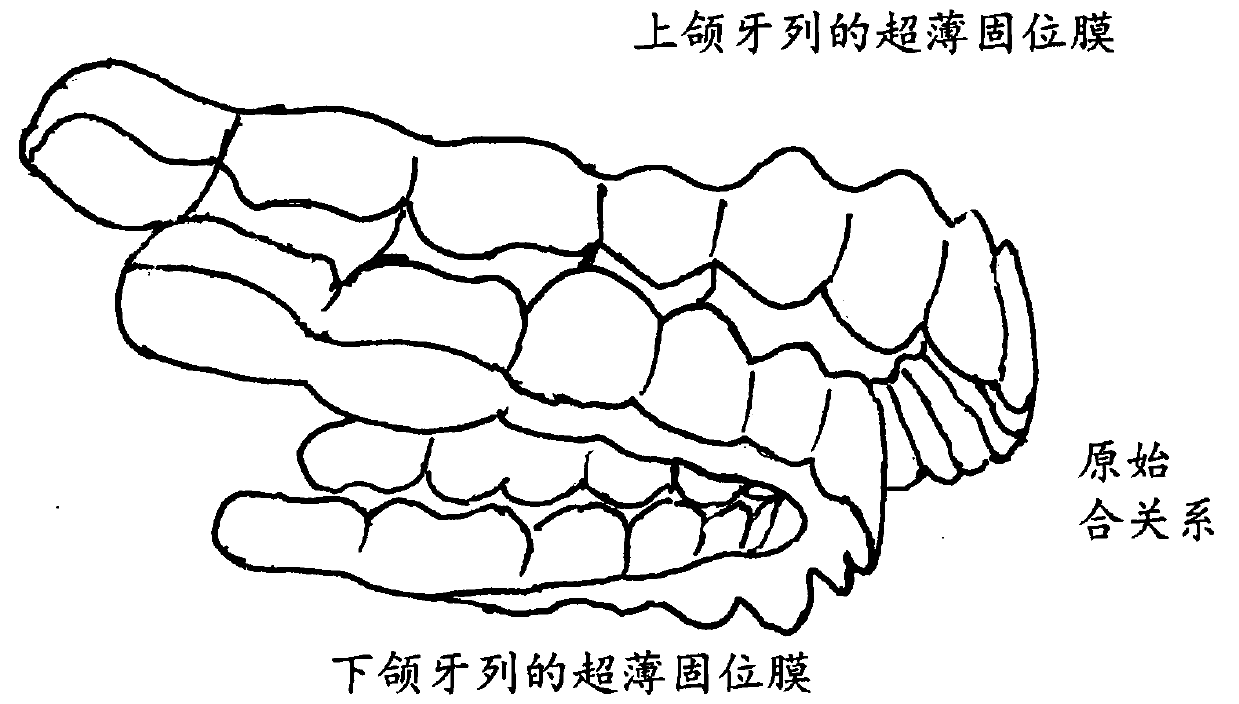

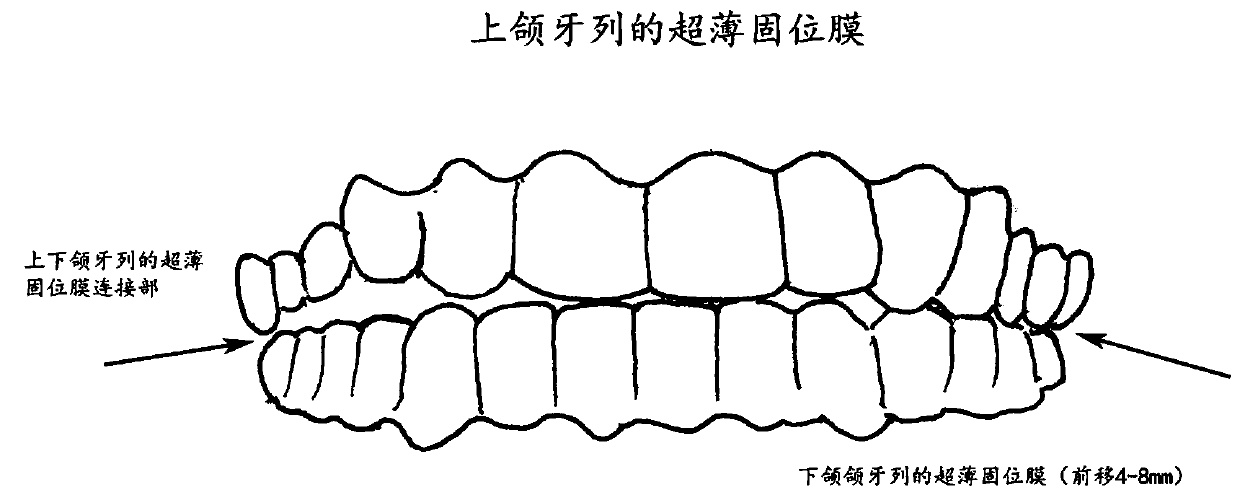

[0031] 3) Transfer of joint relationship: Bring the upper and lower teeth retention film into the oral cavity, and use heated and softened wax sheets to make the joint wax to determine the original joint position. Use this occlusal wax to transfer the occlusal relationship of the upper and lower teeth retention membranes to the adjustable multifunctional jaw frame.

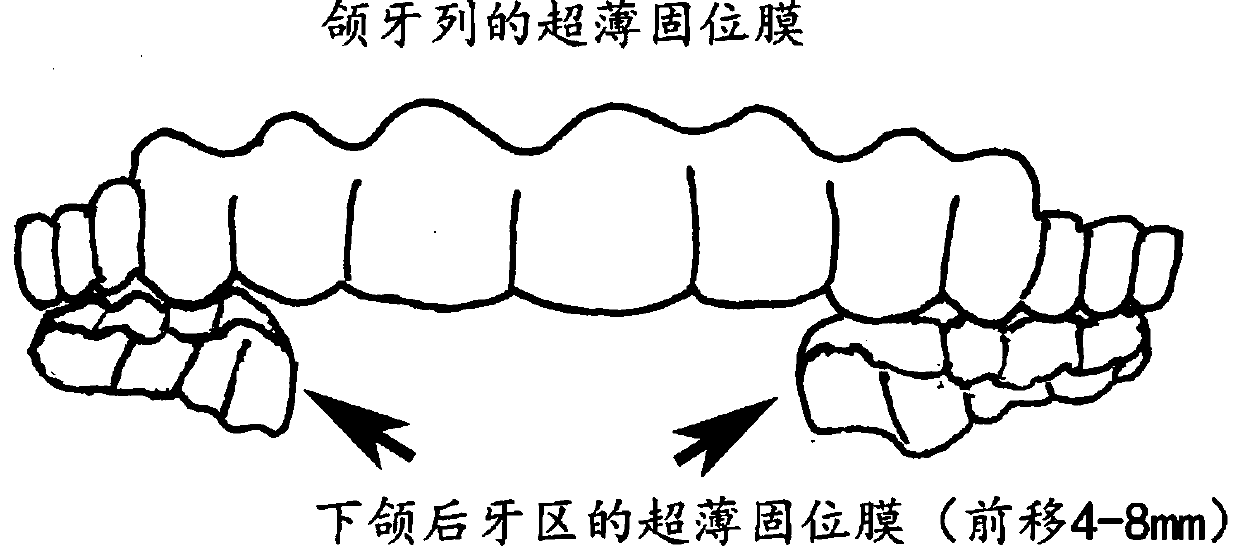

[0032] 4) Occlusal reconstruction: remove the occlusal wax, adjust the jaw frame to adv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com