A detection and calculation method for the friction and wear boundary of the tooth flank of a high-feed milling cutter

A technology of friction and wear and boundary detection, which is applied in the direction of measuring/indicating equipment, metal processing equipment, metal processing machinery parts, etc., can solve the problem that the change characteristics of the cumulative friction and wear boundary cannot be known The formation of the cumulative friction and wear boundary of the cutter tooth flank Process and other problems, to solve the problem of thermal coupling field dissipation, solve the large error of evaluation, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

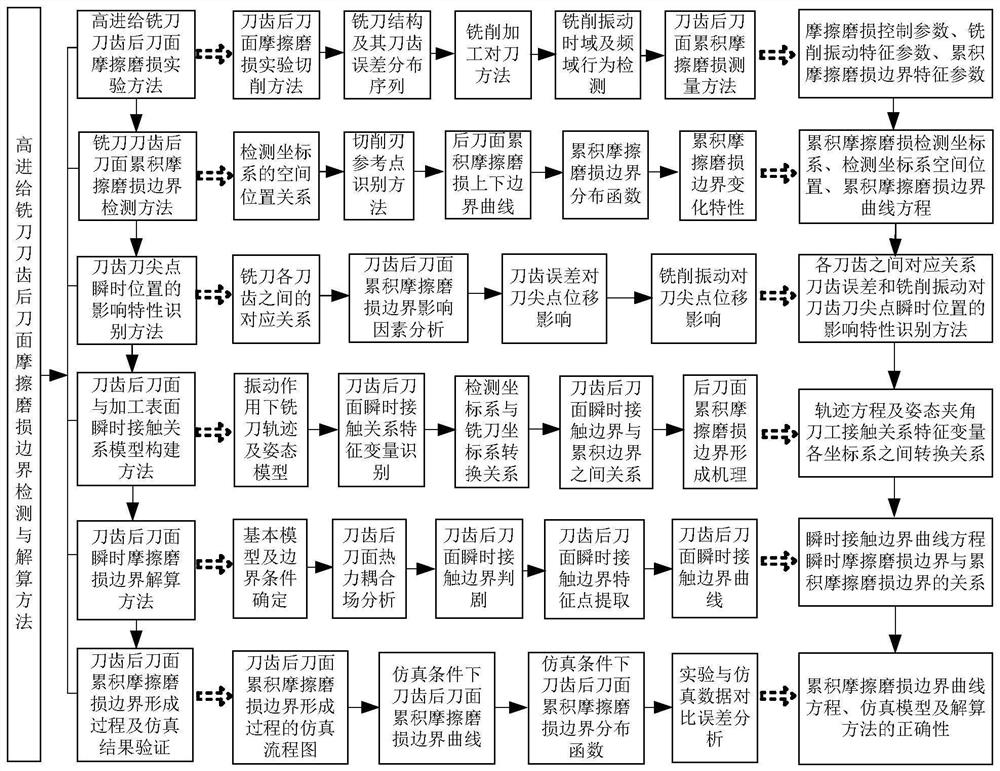

[0099] to combine figure 1 - Fig. 32 illustrates this embodiment. In this embodiment, a high-feed milling cutter tooth flank friction and wear boundary detection and solution method involved in this embodiment includes the following steps:

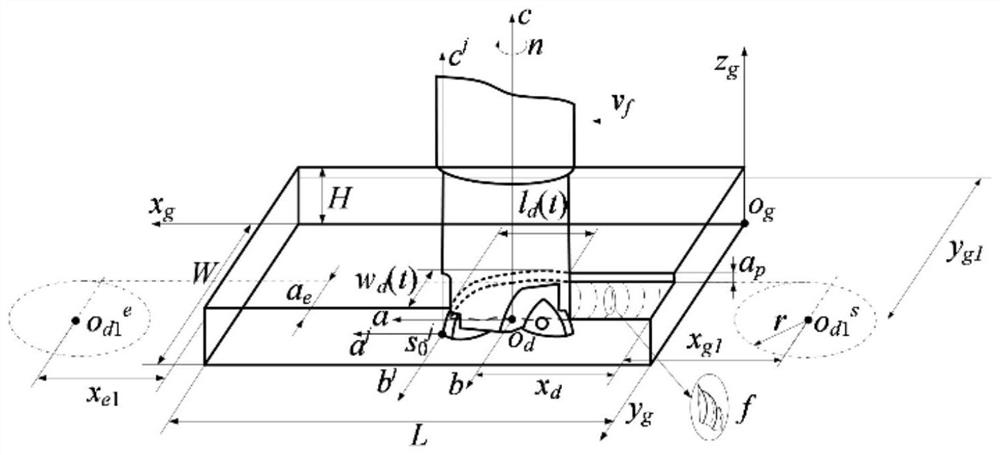

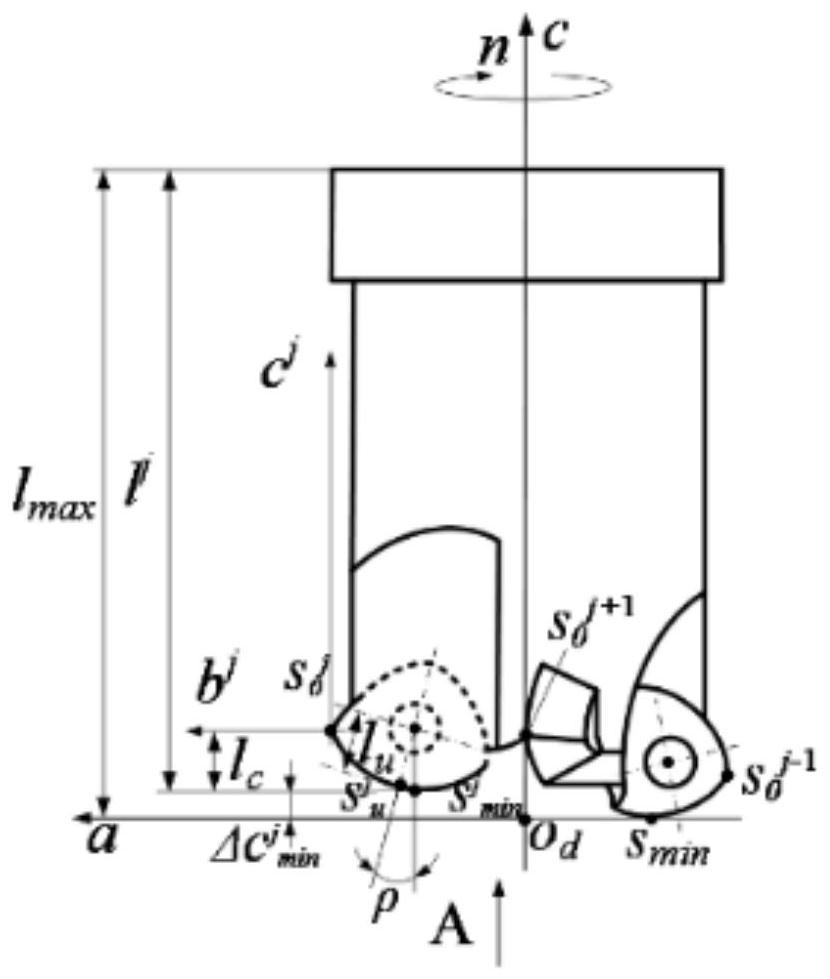

[0100]Step 1. High-feed milling cutter tooth flank friction and wear test method: multiple high-feed milling cutters with the same structure are used to perform milling experiments with different cutting strokes. Extract the geometric structure parameters of the workpiece and the machined surface, and establish the workpiece coordinate system; extract the structural characteristic variables of the milling cutter, and establish the milling cutter coordinate system; extract the characteristic variables of the cutter tooth structure, establish the cutter tooth coordinate system and the cutter tooth error distribution sequence; use the experiment to obtain the vibration Characteristic parameters and friction and wear samples of cutter tooth fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com