Novel tread mouth-shaped plate heating device

A technology of heating device and mouth plate, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of limited heat pipe power and insufficient heat conduction outer mouth plate, and achieve the effect of improving component quality and reducing bad return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

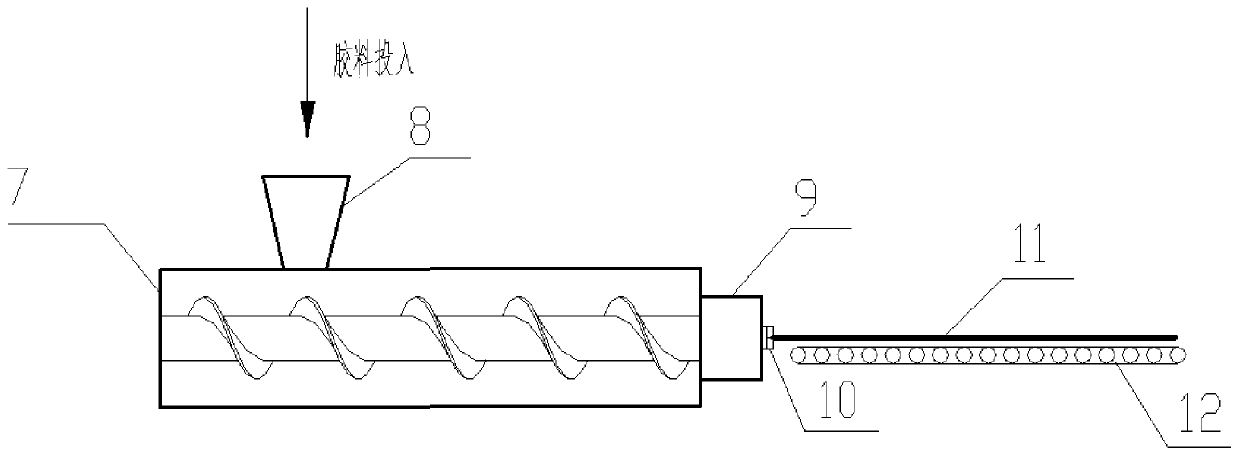

[0018] Such as Figure 1-3 Shown: screw extruder 7, feeding port 8, machine head 9, die 10, tread 11, tread conveyor belt 12, tread outlet 13, the tread is discharged through the die plate, and the die plate is divided into It is an inner mouth type and an outer mouth type, and the inner mouth shape is fixed, and an electric heating tube is embedded inside. The outer opening plate is detachable and divided into upper and lower outer opening plates. The inner and outer mouth plates are separated, and it is difficult for the heat of the electric heating tube of the inner mouth plate to be completely transferred to the outer mouth plate.

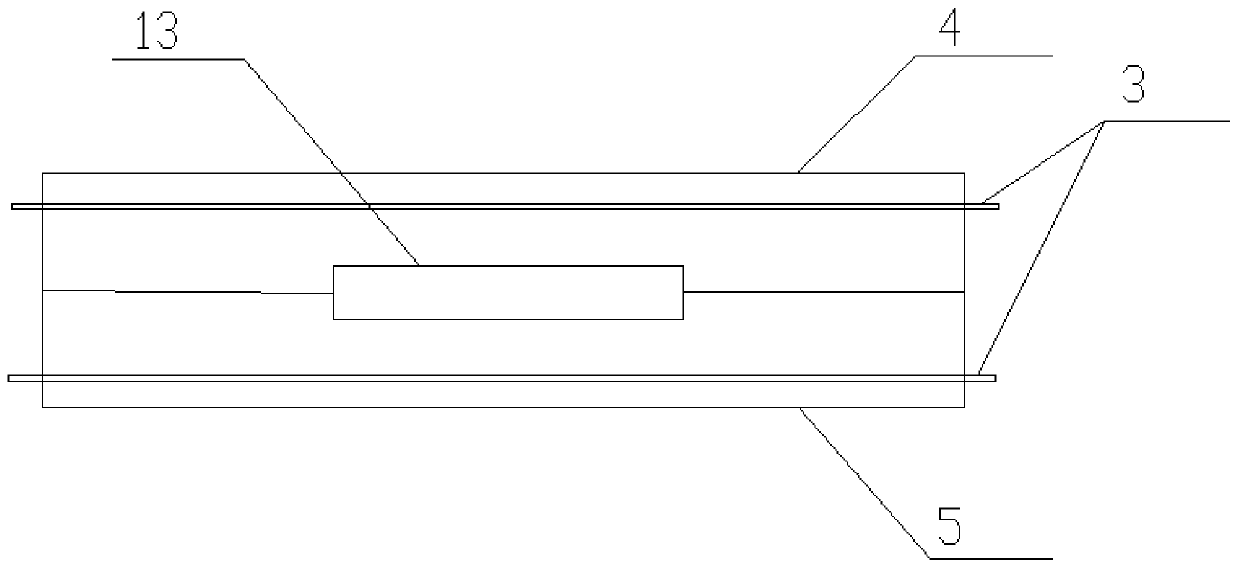

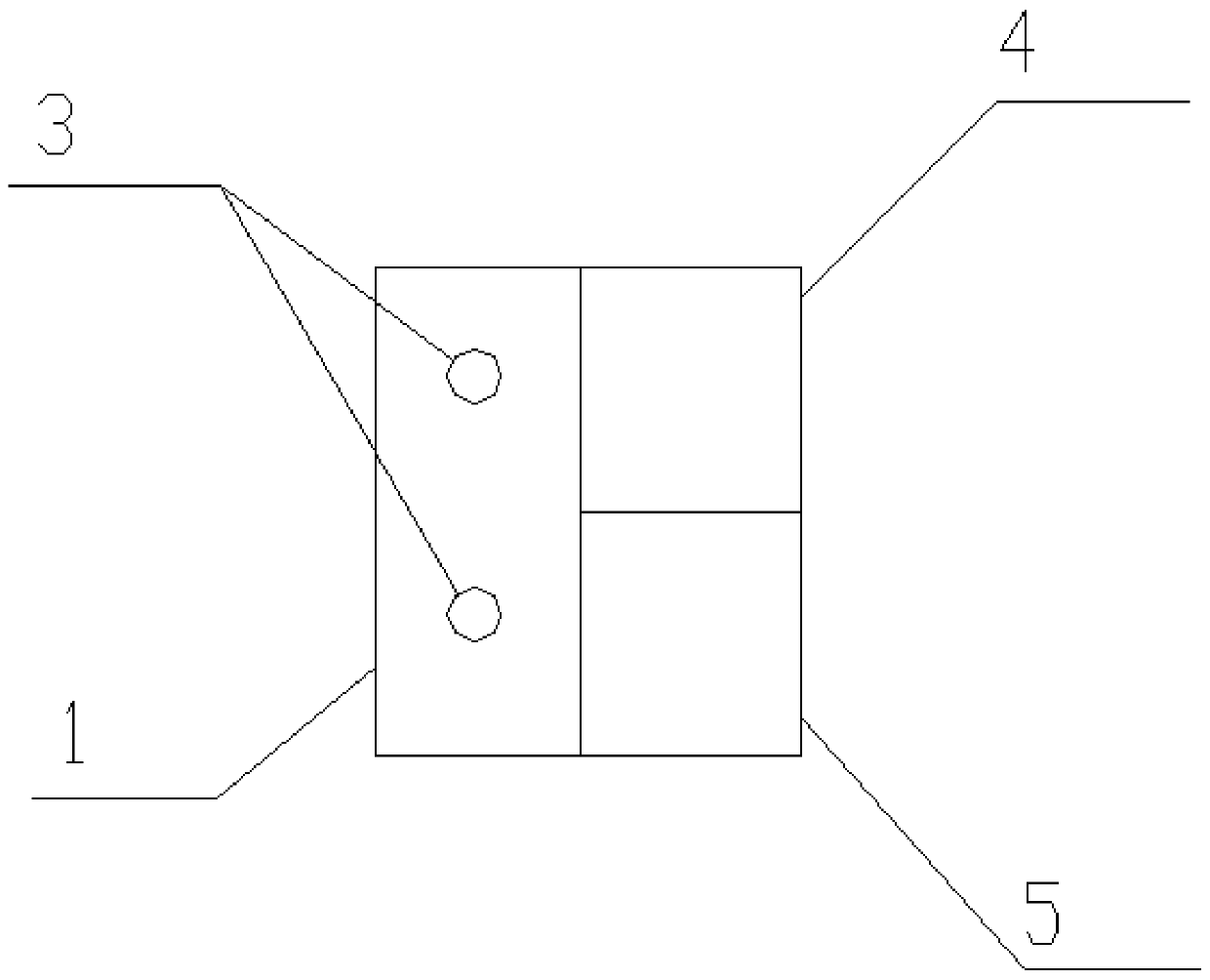

[0019] Such as Figure 4-5 As shown, a tread plate heating device is fixed on one side of the machine head and can be opened and closed flexibly.

[0020] The tread is molded through a die plate, which is divided into an inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com