Fabricated building teaching model

A teaching model and prefabricated technology, applied in teaching models, educational appliances, instruments, etc., can solve the problem of not being able to display the upper and lower structures of prefabricated buildings and the connection relationship of components, and achieve good display effects and good learning effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

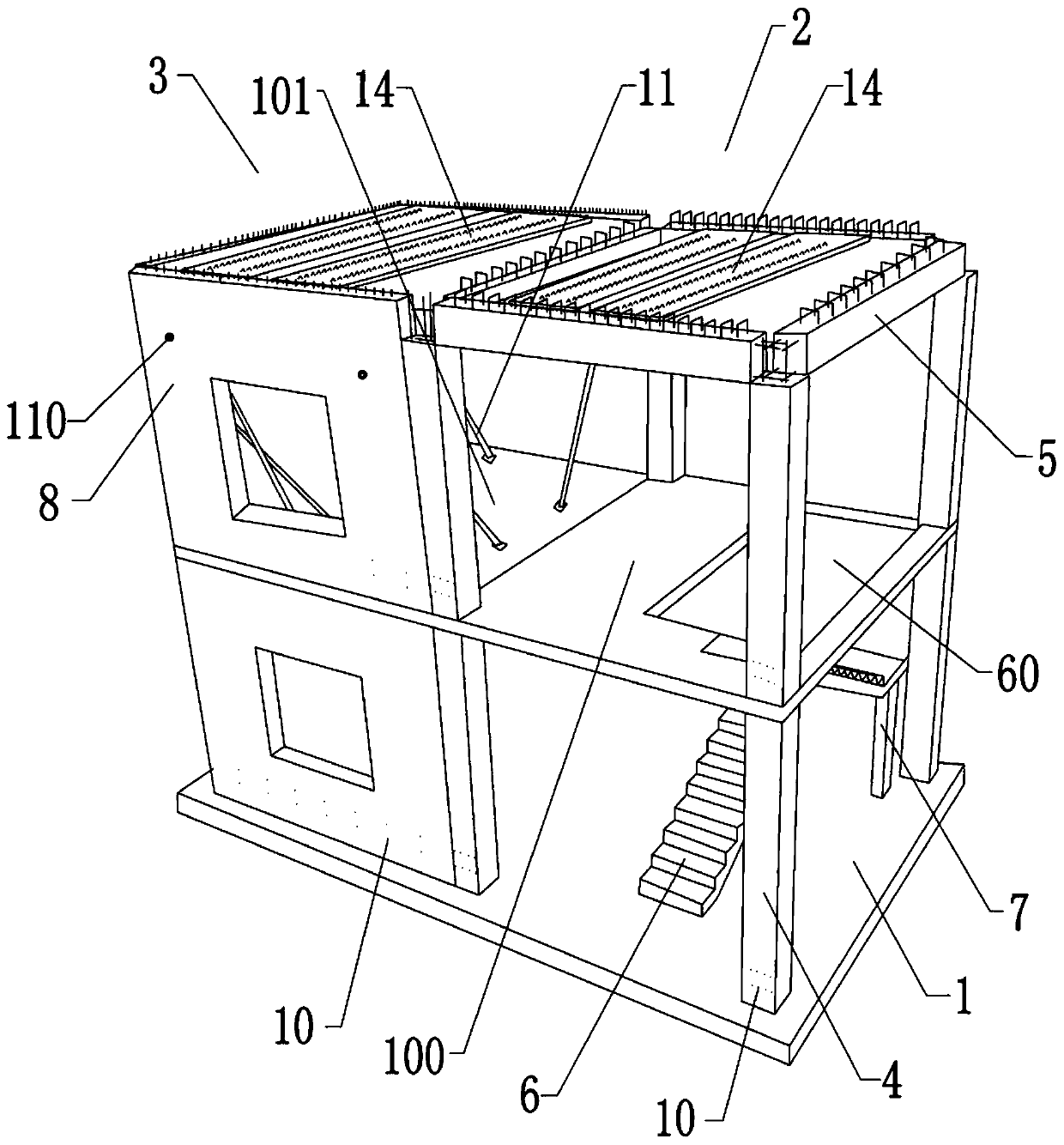

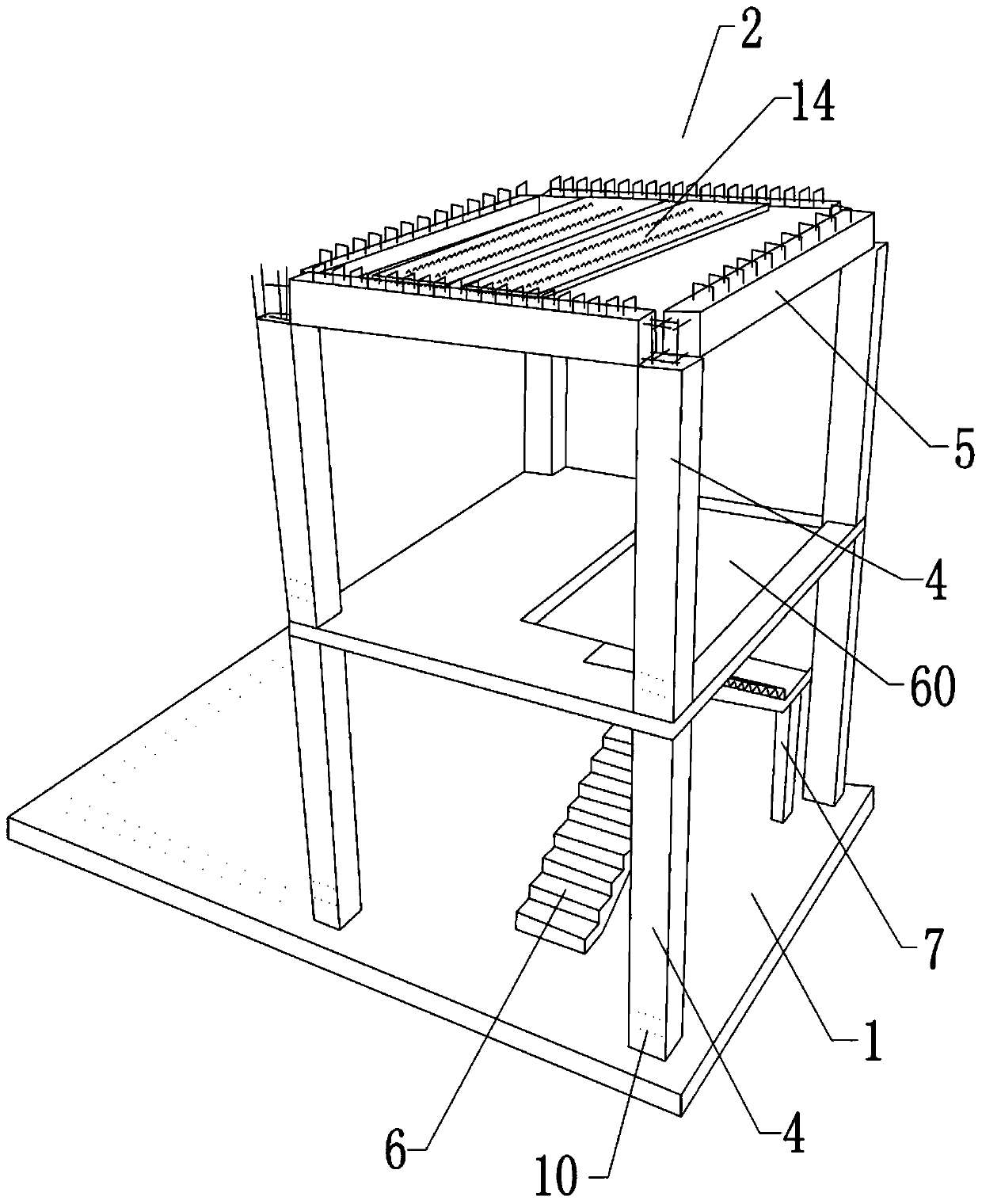

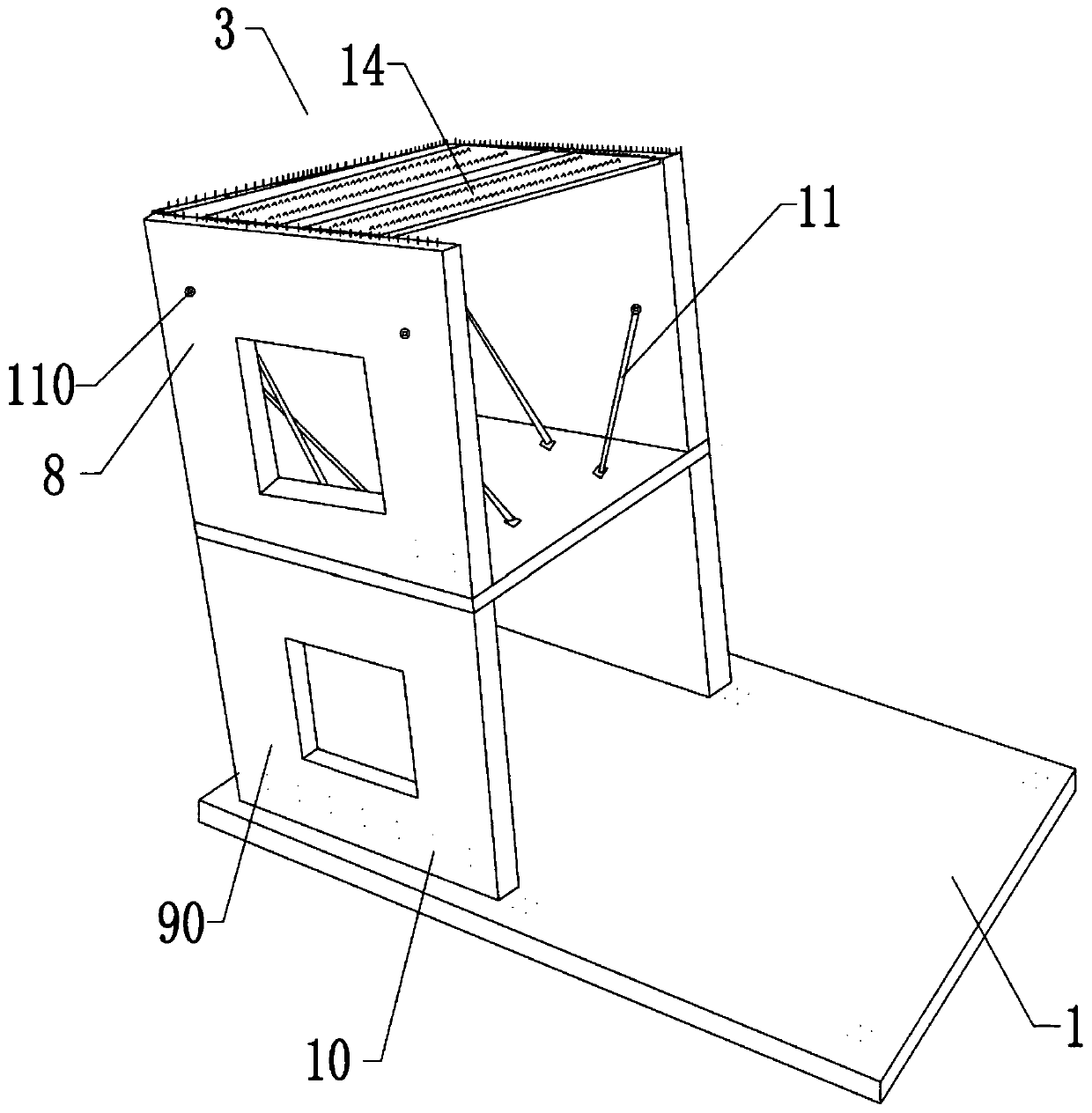

[0039] Such as figure 1 As shown, a solid model of a prefabricated building with a dual-structure system includes a base plate 1 and a prefabricated shear wall structure display area 3 and a prefabricated frame display area 2 horizontally arranged on the base plate 1. The prefabricated shear wall structure display area 3 and the prefabricated frame display area 2 both include the first floor and the second floor, and the height of each floor is 0.2-0.25m (preferably 0.22m or 0.23m).

[0040] combine figure 1 and Figure 4 As shown, the first and second floors of the prefabricated frame display area 2 both include four prefabricated columns 4 distributed in a matrix, and the axes of the prefabricated columns 4 on the first and second floors are aligned.

[0041] The prefabricated column 4 structure of the first floor of the prefabricated frame display area 2 is as follows Figure 9 As shown, the top and bottom of the prefabricated column 4 on the first floor are provided wit...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 is that: Figure 12 and Figure 13 As shown, the present embodiment adds a packaging mechanism on the basis of Embodiment 1. The packaging mechanism includes four side panels 20 that are rotatably connected to the four edges of the bottom panel 1 through hinges 200, and the edge of one side panel 20 The cover plate 21 is rotatably connected to the hinge 200, and the three edges of the cover plate 21 are rotatably connected to the fixing strip 210 through the hinge 200, and the fixing strip 210 is fixed to the other three side panels 20 by magnetic buckles, that is, fixed A magnetic female buckle 2100 is arranged on the bar 210 , and a magnetic sub-buckle 2101 is arranged on the side plate 20 .

[0053] Magnets are provided on the inner sides of the side plates 20, and the components in the prefabricated shear wall structure display area and the prefabricated frame structure display area are provided with an adsorp...

Embodiment 3

[0057] The difference between the present embodiment and the second embodiment is that: Figure 14 As shown, in the present embodiment, handles 16 are installed on two opposite side panels 20, and the two side panels are provided with fasteners for locking the fixing strip 210, and the fasteners include fixing on the side panels 20 The threaded sleeve 17 on the top, the threaded sleeve 17 is threadedly connected with the screw rod 15, and the fixing bar 210 is provided with a threaded hole for the top of the screw rod 15 to penetrate.

[0058] When carrying the whole model, people hold two handles 16 for carrying. In order to prevent the magnetic buckle from being untied, the screw rod 17 is screwed upwards, and the screw rod 17 is screwed into the threaded hole on the fixing bar 210, thereby realizing further locking of the fixing bar 210 and avoiding the magnetic force between the fixing bar 210 and the side plate 20. The clasp is undone to prevent the model from unraveling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com