Automatic assembling system for standard test motor and assembling method

A standard test and automatic assembly technology, applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve the problems of heavy workload and labor, low production efficiency, difficult assembly, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0054] Example 1:

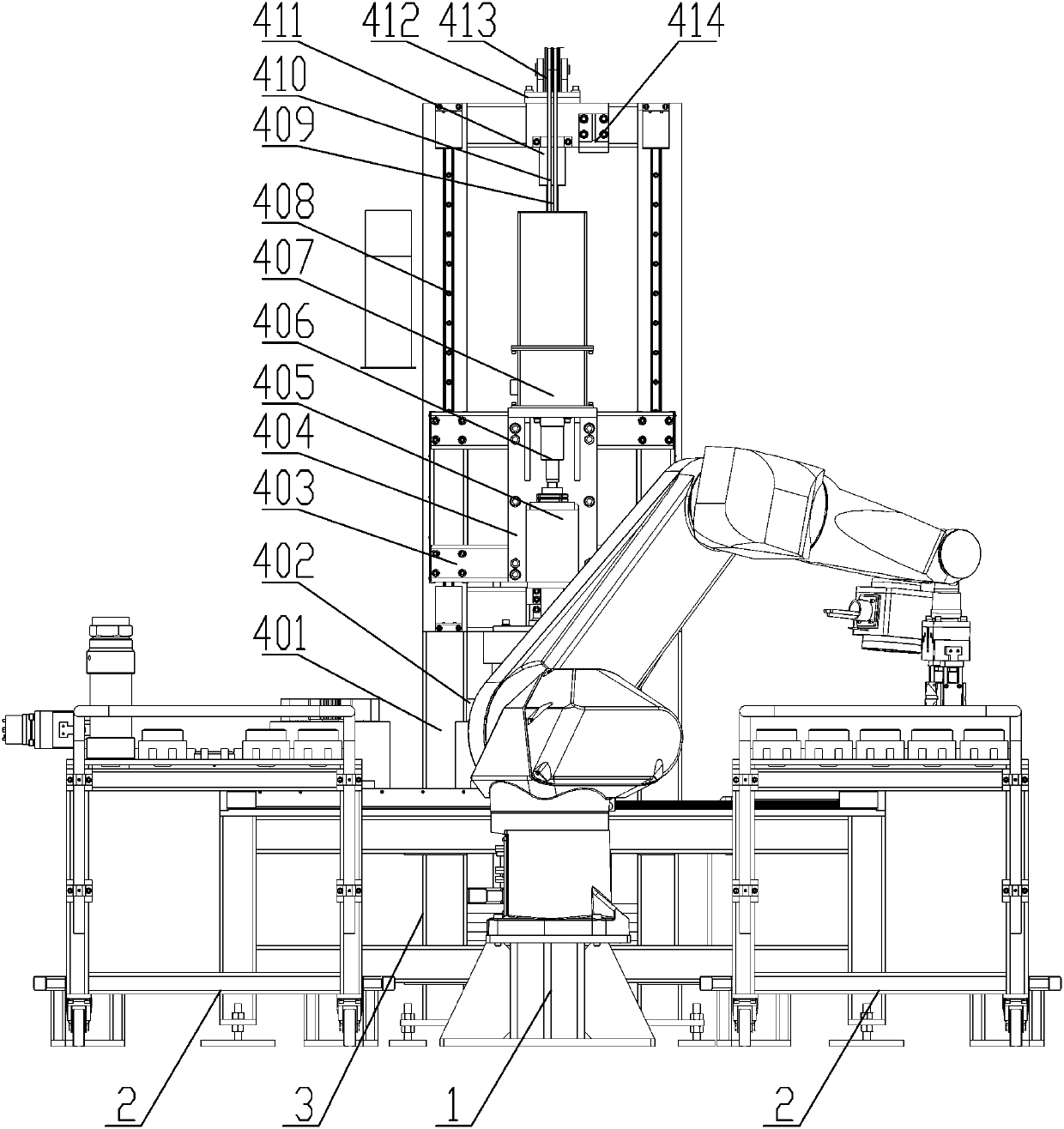

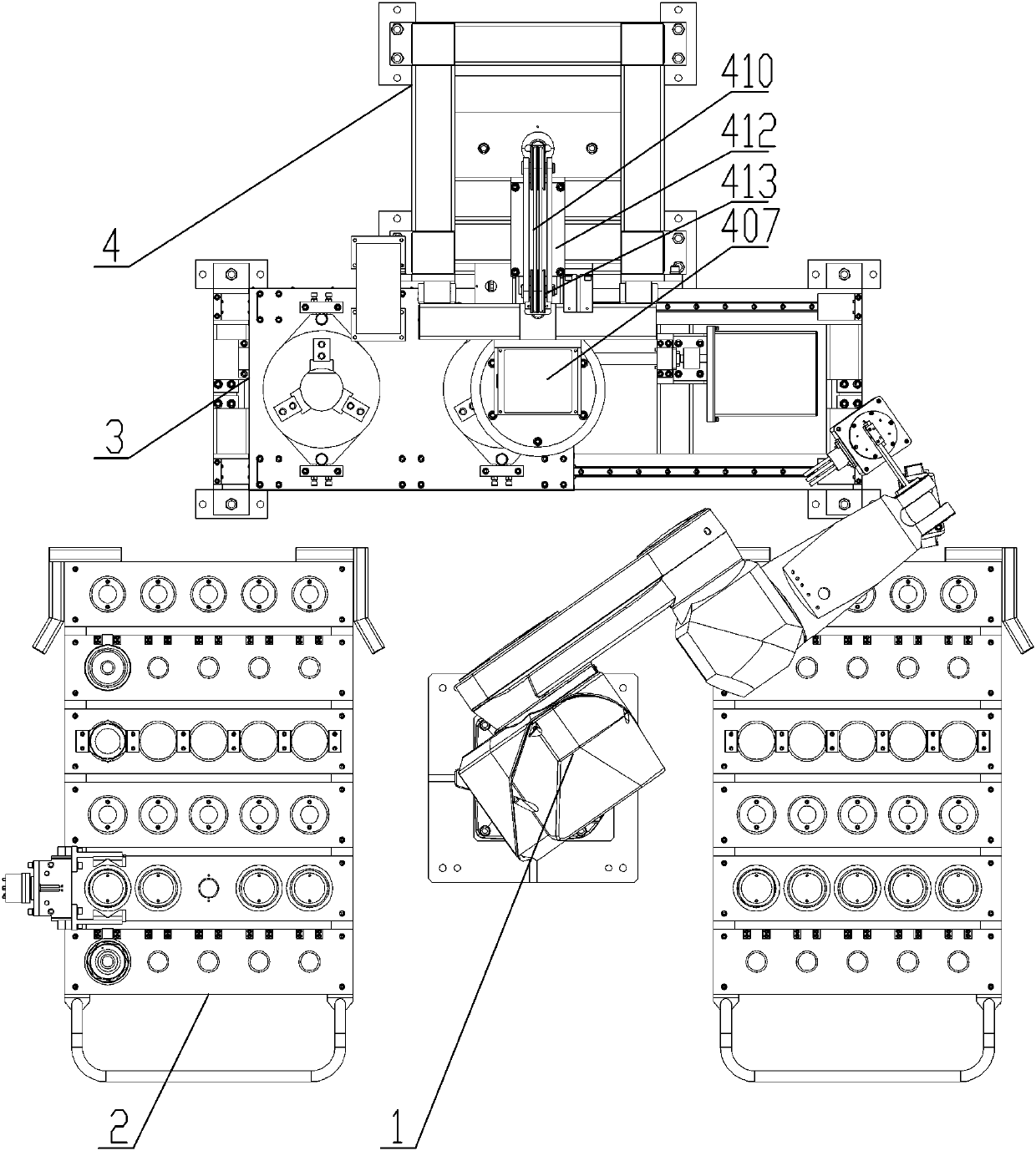

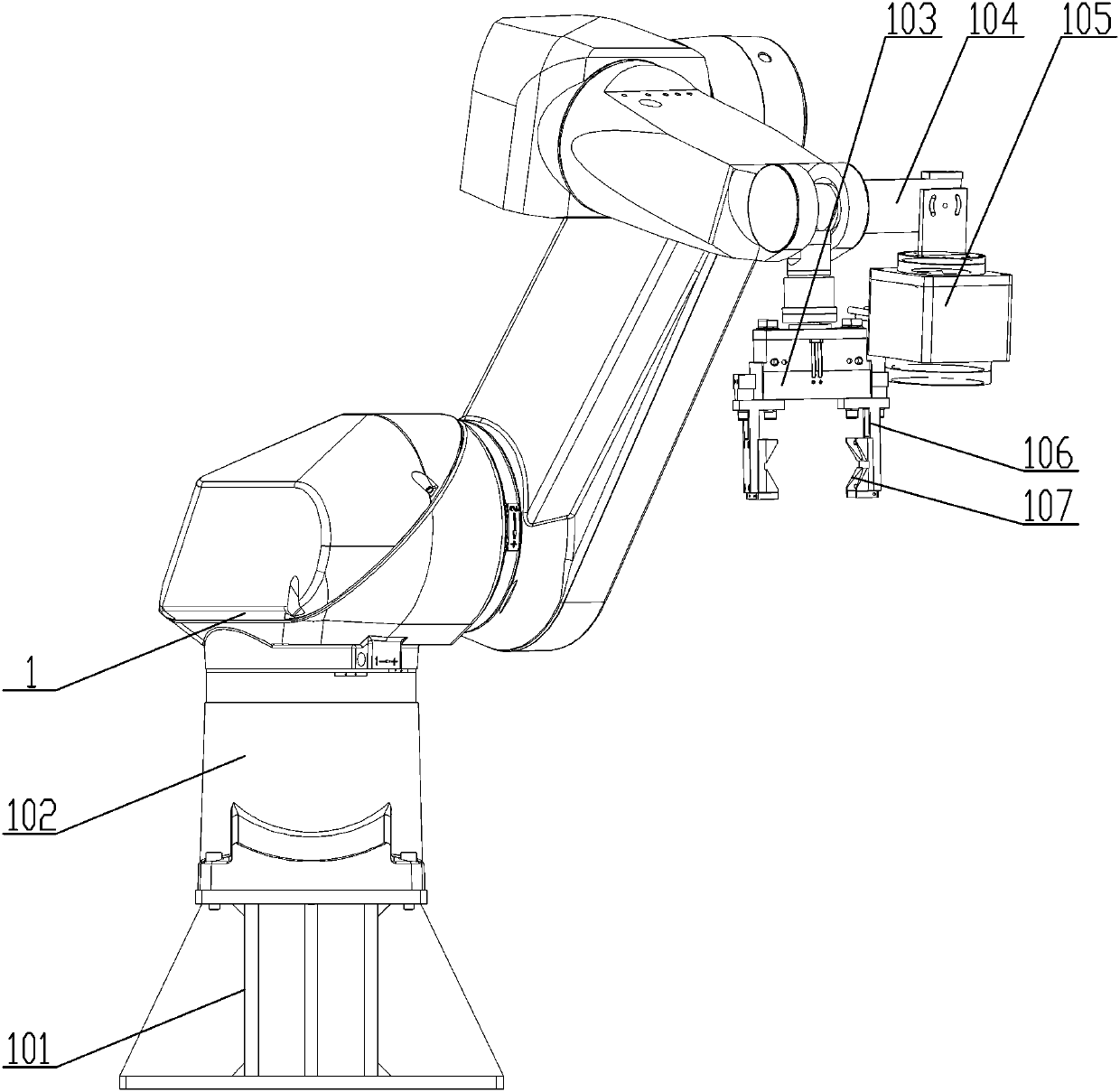

[0055] see Figure 1-4 , a standard test engine automatic assembly system, which includes a plurality of mobile tooling platforms 2 for placing and carrying various parts of the standard test engine to be assembled, the middle position of the mobile tooling platform 2 is fixedly installed for A multi-free manipulator 1 for clamping and placing parts, the side of the multi-free manipulator 1 and the mobile tooling platform 2 is provided with a transmission line body 3 for clamping and fixing parts to be assembled, and the transmission line body 3 The rear side is provided with a tightening device 4 for tightening the components to be assembled. The automatic assembly system with the above structure can be used for the connection and tightening of threaded connectors and threaded fasteners in the automatic production process of standard test engines, and can be automatically tightened at a constant torque with the cooperation of the transmission line body 3 ...

Example Embodiment

[0079] Example 2:

[0080] The method for engine assembly performed by the standard test engine automatic assembly system includes the following steps:

[0081] Step1: Place the nozzle and nozzle seat to be assembled on the nozzle tooling 206 of the mobile tooling platform 2 after pre-assembly, and respectively place the connecting sleeve, engine body, gasket and pressure measuring seat on the connecting sleeve tooling 208, Body tooling 210, gasket tooling 212 and pressure measuring seat tooling 214; and place two mobile tooling platforms 2;

[0082] Step2: Manually push the mobile tooling platform 2 full of parts to the isolation room, and set it on both sides of the multi-free manipulator 1 after being positioned by the platform limit frame 201;

[0083] Step3: Start the multi-free manipulator 1. The multi-free manipulator 1 recognizes and grabs the parts through the industrial camera 105 and the manipulator claw 103 at the end according to the assembly process, and then ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com