Clay numerical control milling clamping platform and clamping method

A CNC milling and platform technology, applied in the direction of clamping, positioning device, support, etc., can solve the problems of poor repeat positioning accuracy, waste of time, large human influence factors, etc., and achieve the effect of fast clamping and alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

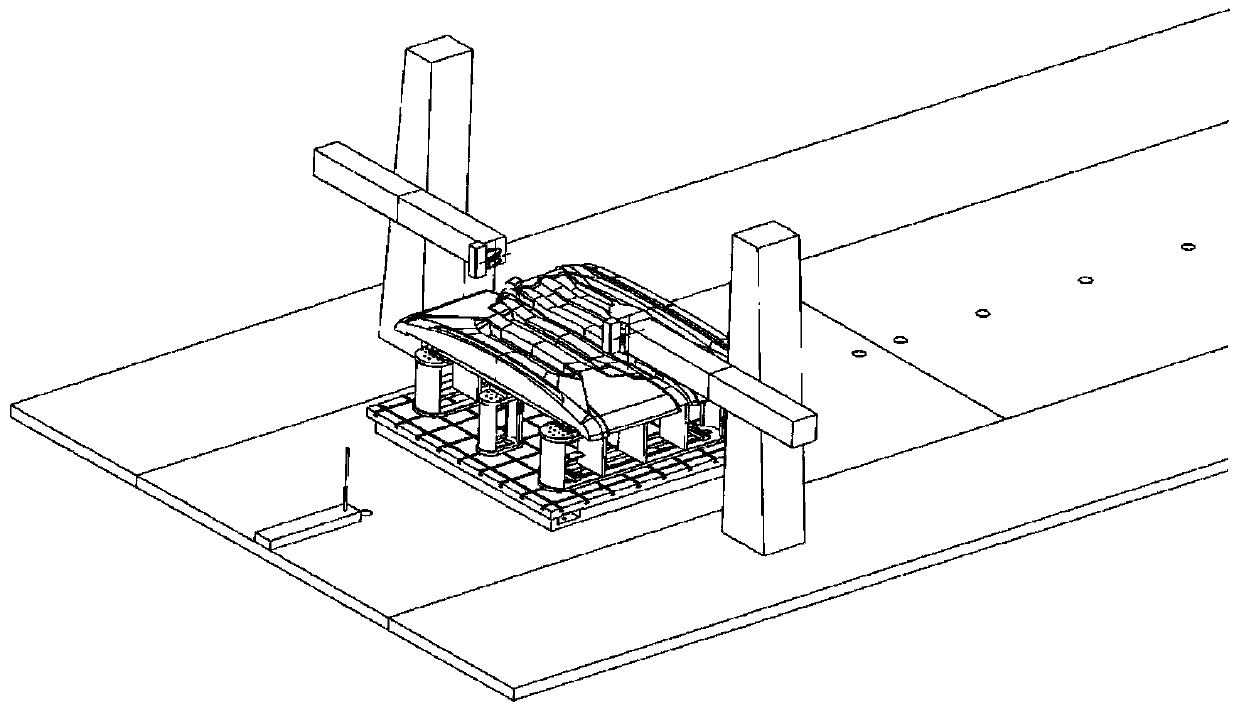

[0036] The technical solutions of the present invention will be further explained and illustrated in the form of specific embodiments in conjunction with the accompanying drawings.

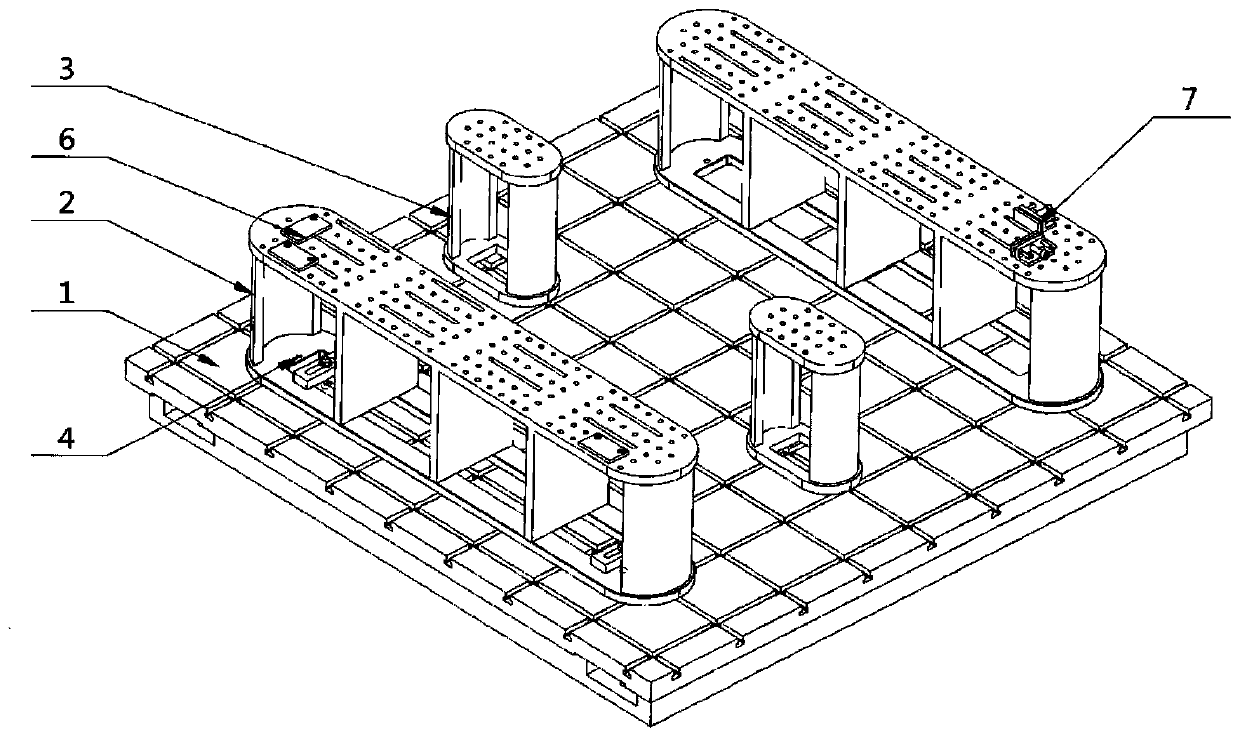

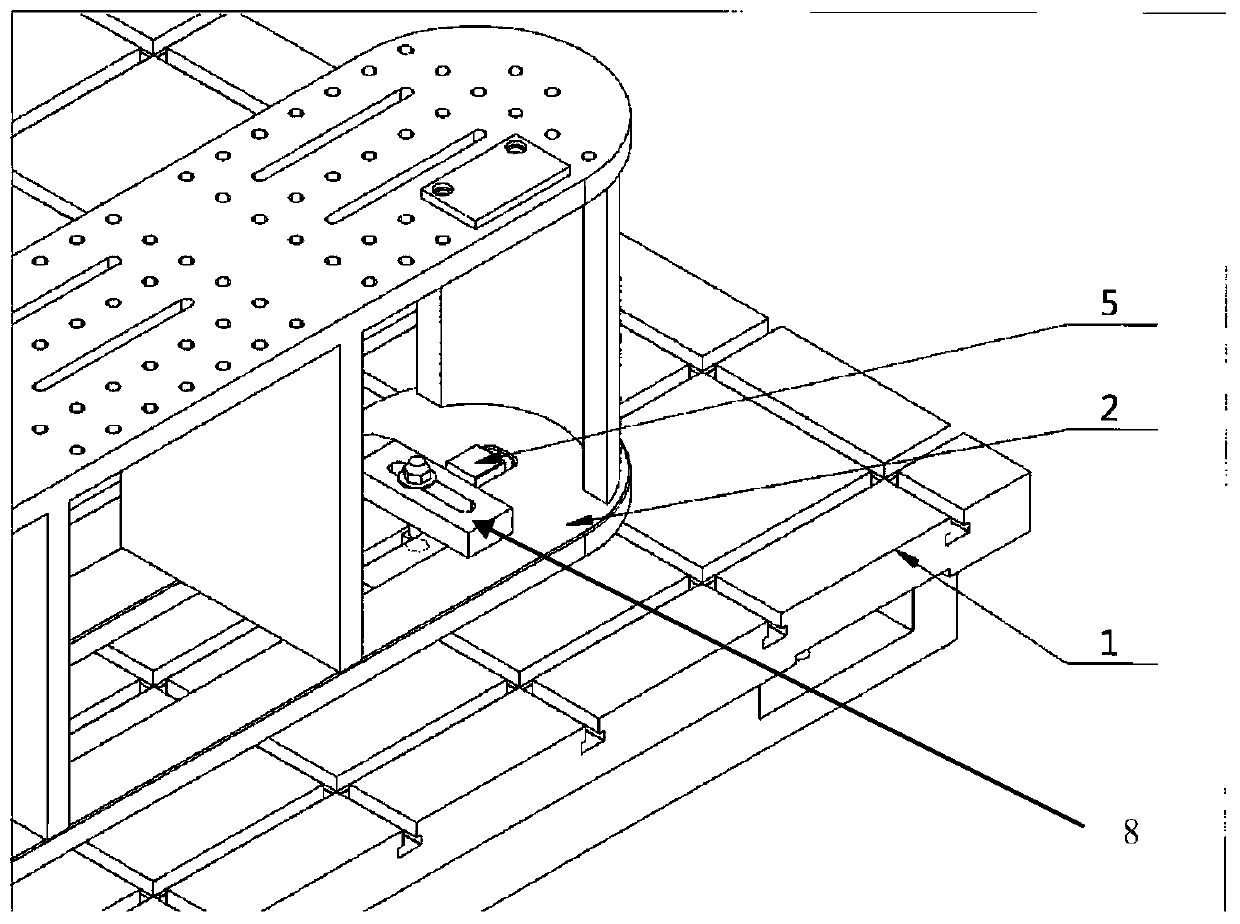

[0037] Such as figure 2 As shown, a clamping platform for oil sludge CNC milling, the platform includes a T-slot platform 1, a long stool 2, a short stool 3, a rotating shaft 4, a limit block 5, a fixed positioning block 6, a movable positioning block 7 and a fixed block 8;

[0038] Wherein, said bench 2 is as Figure 5a ~ Figure 5d As shown, the upper and lower end faces are oblate, and the upper and lower end faces are fixed by several support columns; image 3 As shown, the center of one end of the flat circle is the center of rotation, and a mounting hole for the rotation shaft 4 is opened on the center of rotation of the lower end face, as shown in Figure 7a ~ Figure 7c As shown, the upper end of the rotating shaft 4 is installed in the mounting hole, and the lower end is installed at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com